Swing table on self-hardening sand molding production line

A vibrating table and production line technology, which is applied in the direction of molding machines, casting molding equipment, manufacturing tools, etc., can solve the problems of unsatisfactory use effect and unreasonable structural design of the vibrating table, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail in conjunction with the illustrated embodiments thereof.

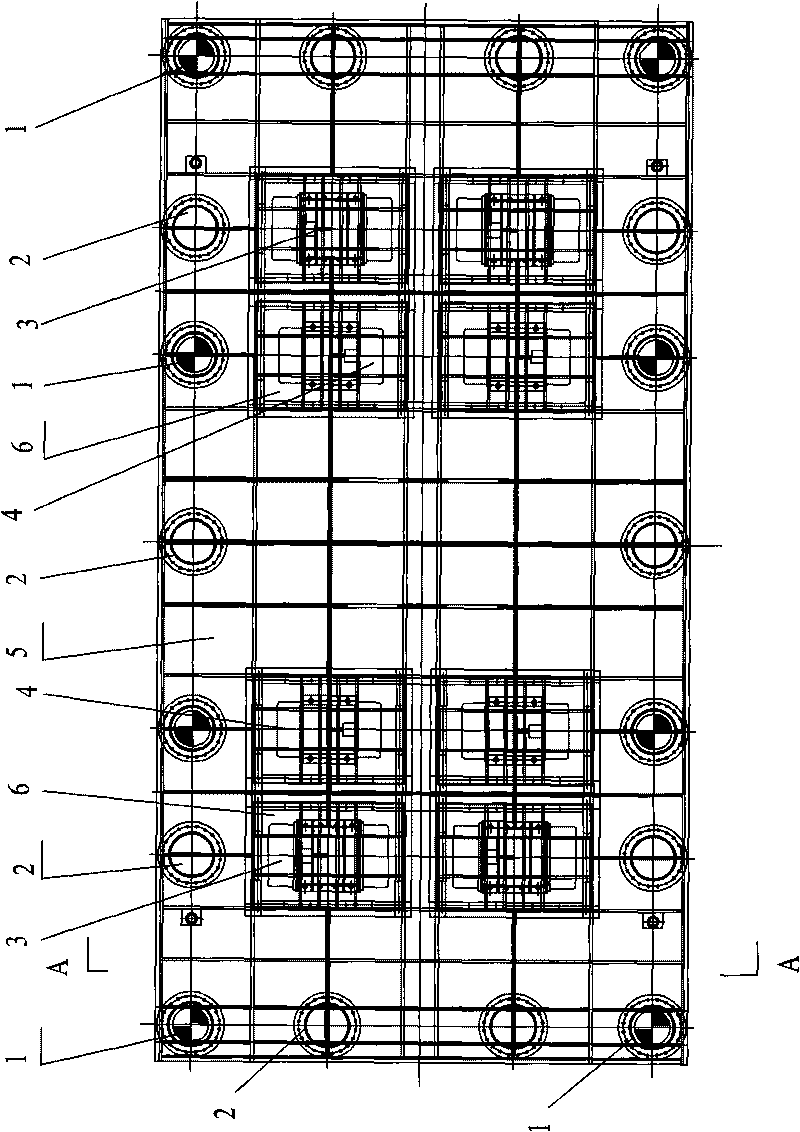

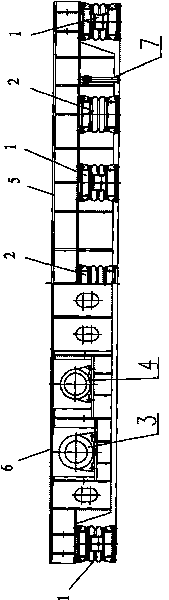

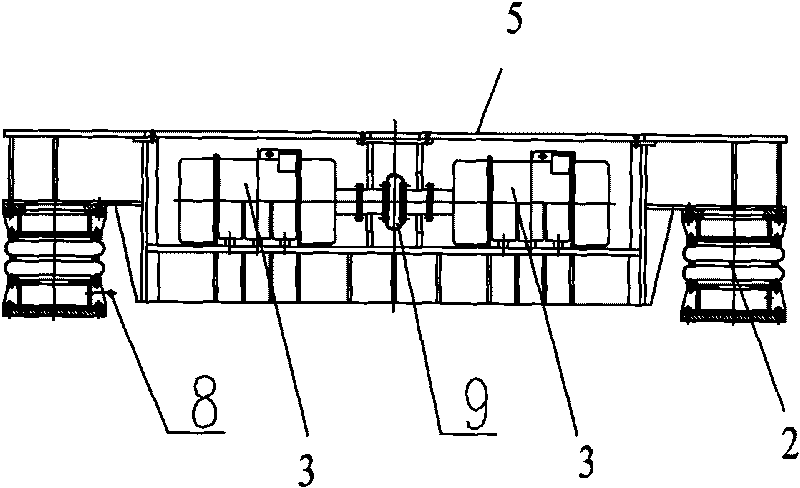

[0014] As shown in the figure, a vibrating motor is arranged in the vibrating table 5, and an inspection guard plate 6 for overhauling and protecting the vibrating motor is arranged on the vibrating table 5 above the vibrating motor; Spring 2 and air spring 1 with support, universal connector 9 is arranged between the main shafts of two adjacent vibrating motors on the same axis; 2 and the supported air spring 1 provide the air supply line 8 of the air source.

[0015] The vibration motor includes a high frequency vibration motor 3 and a frequency modulation vibration motor 4 . A detection device 7 is arranged on the vibration table 5 . Rubber springs are included in the supported air spring 1 .

[0016] There are two groups of vibration motors, each group of vibration motors has two high-frequency vibration motors 3 and two frequency modulation vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com