Fully automatic paper tube machine

A paper tube machine, fully automatic technology, applied in the direction of cardboard winding articles, etc., can solve the problems of high manufacturing cost, low production efficiency, large material loss, etc., to eliminate human differences, improve production capacity and labor efficiency, pass rate and quality The effect of indicator improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

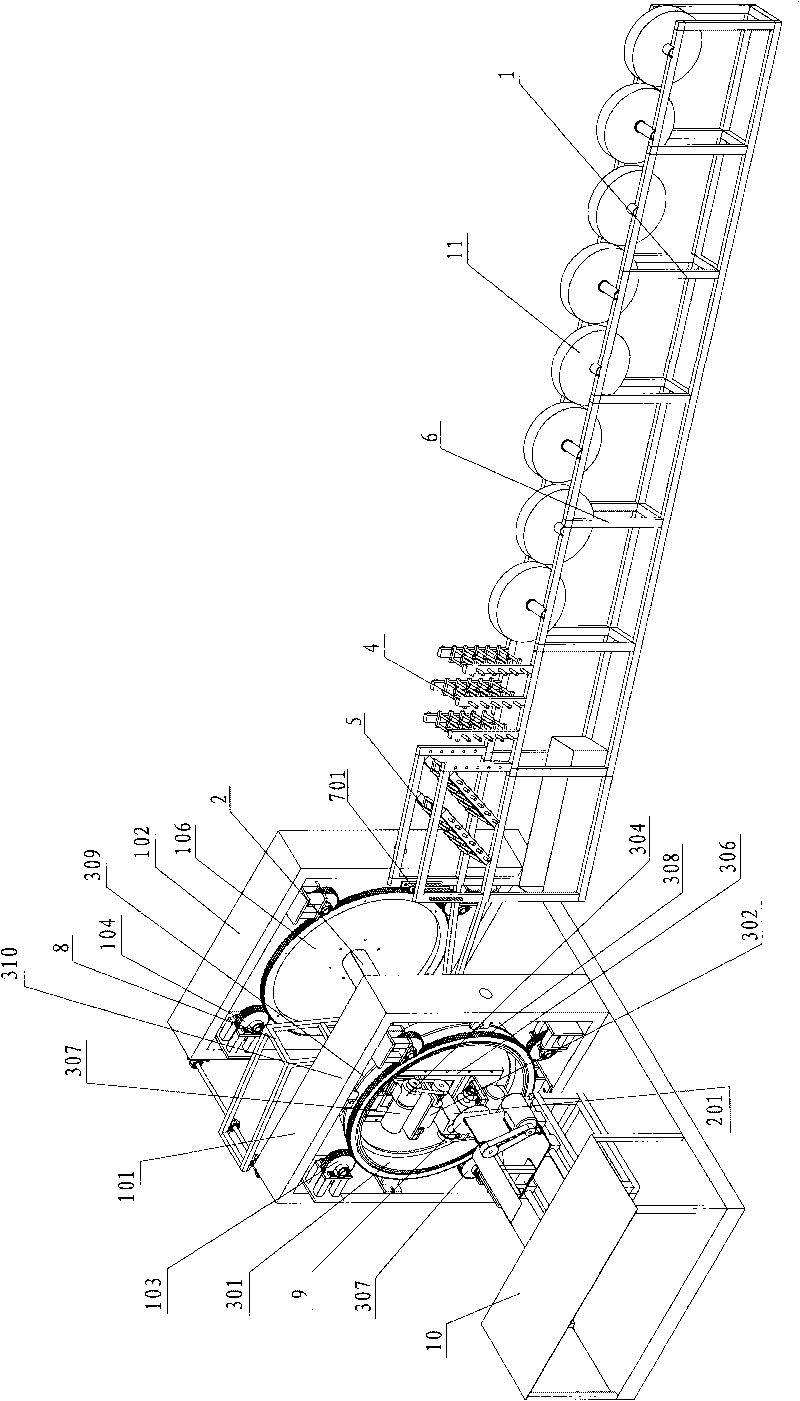

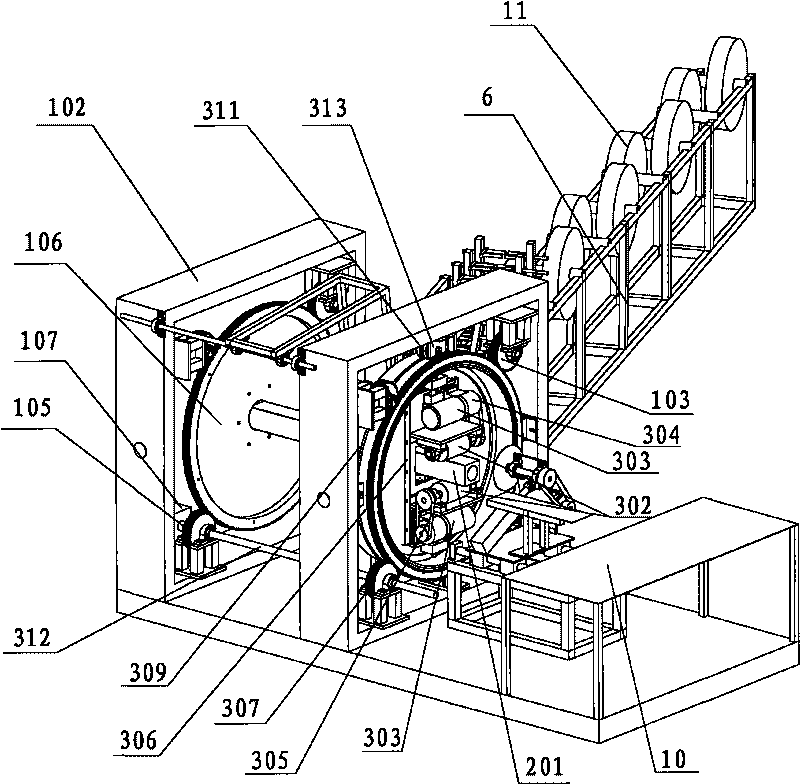

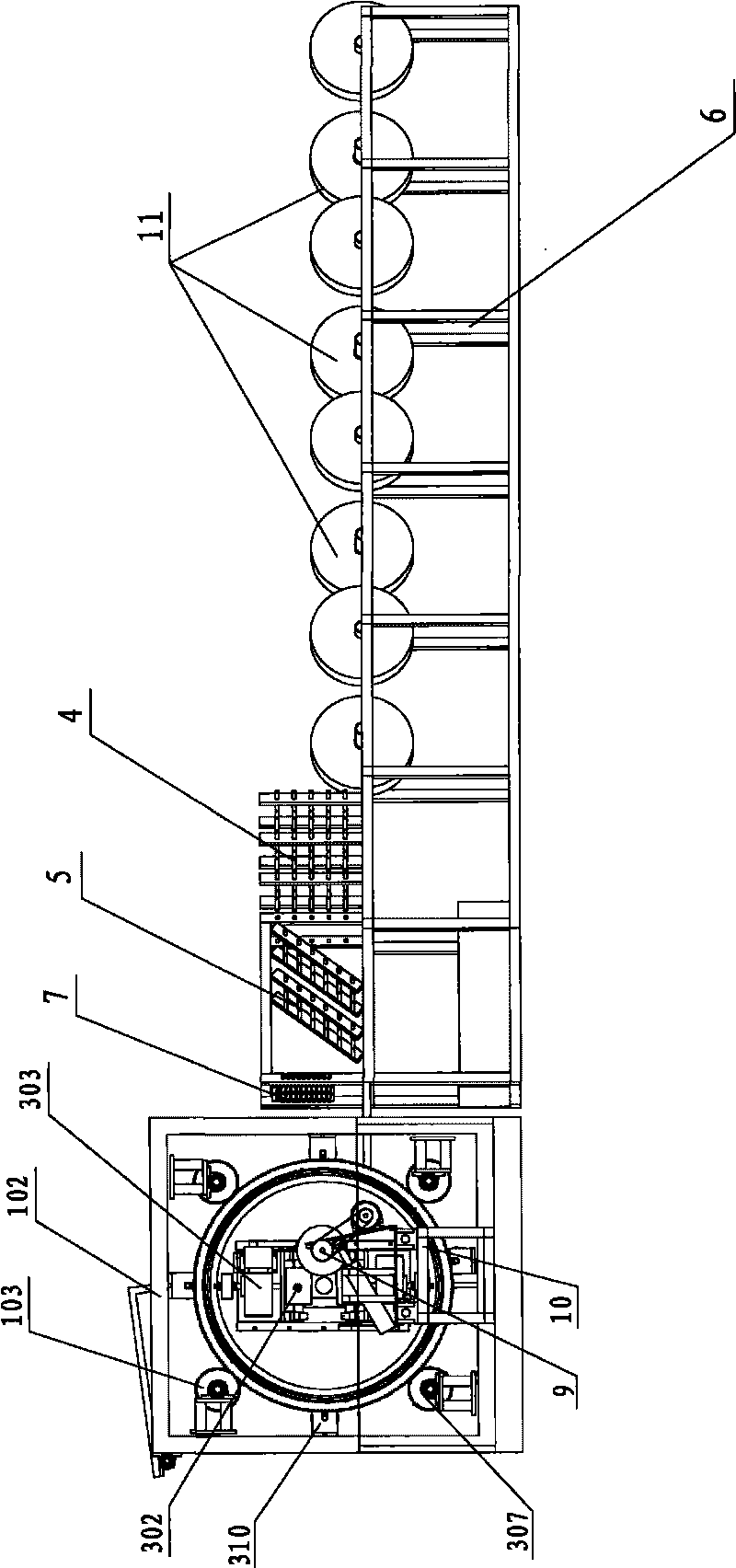

[0063] Such as Figure 1 to Figure 9 As shown, the automatic paper tube machine of the present invention includes: an uncoiling glue coating frame 1, a machine base, a rotating mandrel 2, a damping device 8 and a driving traction device.

[0064] The driving traction device includes a first turntable 301 and a plurality of synchronously rotating drive traction rollers 302 arranged on the surface of the first turntable 301, such as figure 1 , figure 2 As shown, the first motor 303 is connected to the reducer 304 through the belt 305, and the reducer 304 is connected to the driving traction roller 302, and drives the driving traction roller 302 to rotate.

[0065] The base includes two opposite first frames 101 and second frames 102 . The driving traction device is arranged in the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com