Automatic on-line printing machine

A printing machine, automatic technology, applied in the direction of printing machine, printing, general parts of printing machinery, etc., can solve the problems affecting the development of automatic casting/printing methods, low efficiency of automatic casting/printing, etc., to shorten the production cycle, The effect of avoiding human error and improving unit production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is implemented like this:

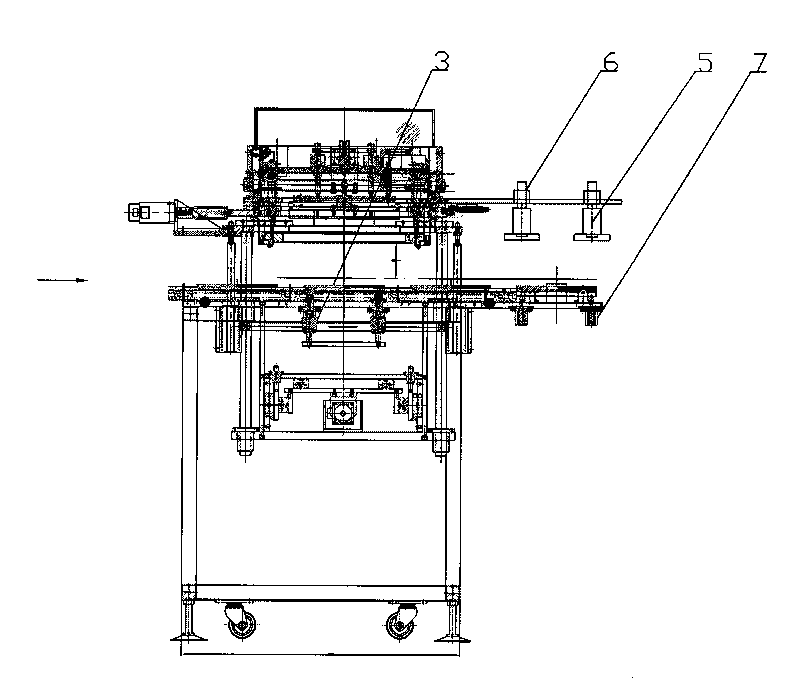

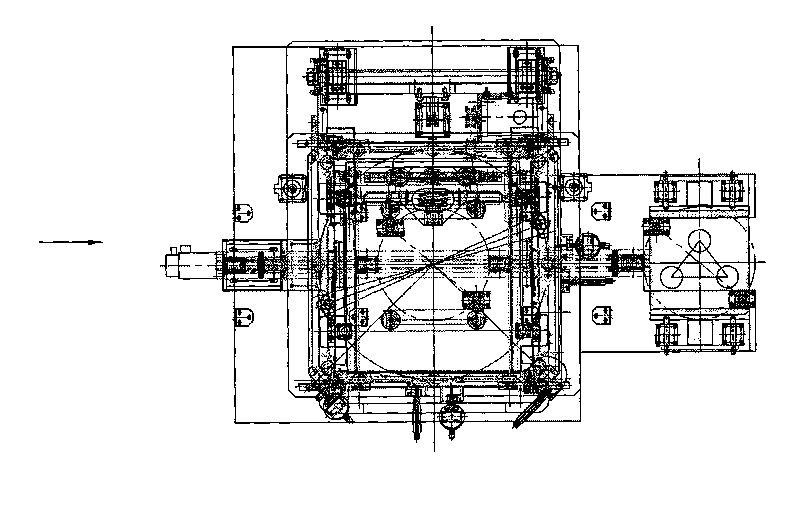

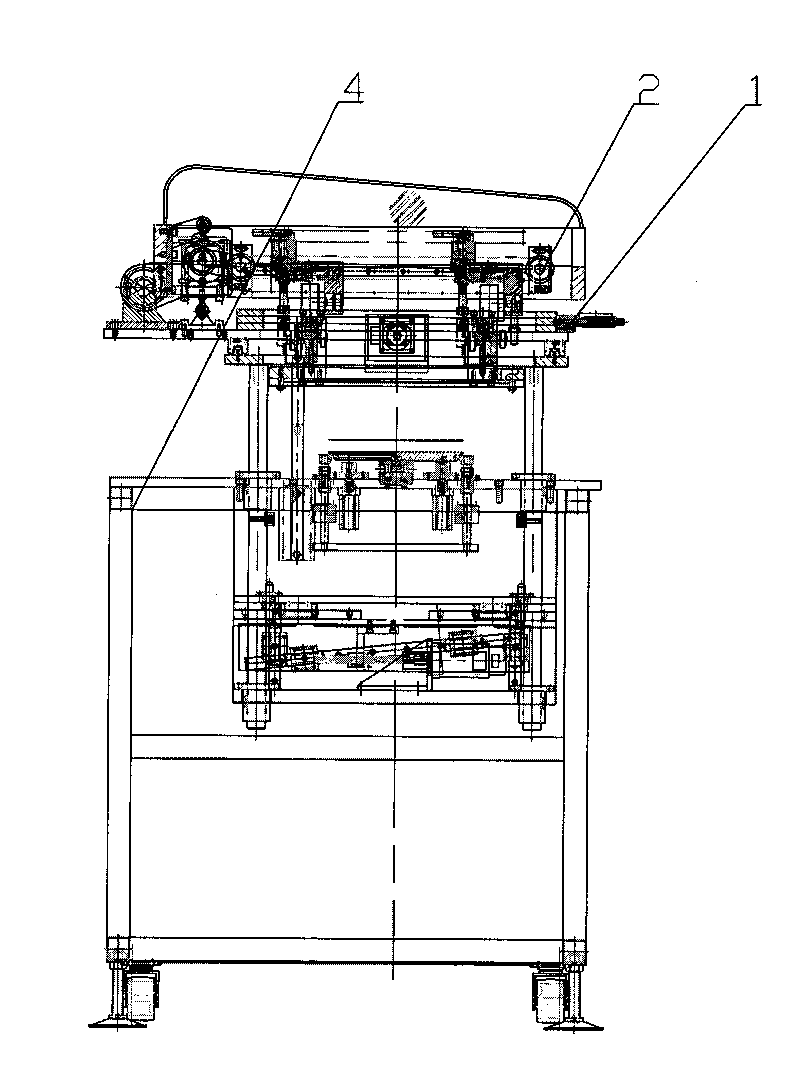

[0024] An automatic online printing machine for automatic printing of substrates, which includes a frame 4 and a support portion 21 for placing the substrate, the support portion 21 is arranged above the frame 4, and the frame 4 is provided with:

[0025] 1), the printing system 2, the printing system 2 spreads materials on the screen through a steel knife, and the rubber knife prints patterns on the substrate;

[0026] 2), three-dimensional correction system 1, the three-dimensional correction system is used to adjust the X, Y and α angles of the pattern;

[0027] 3), lifting system 3, the lifting system 3 is used to make the overall upper part of the equipment lift up and down, and is used to adjust the Gap value of printing;

[0028] 4), the positioning mechanism 7, the positioning mechanism 7 adopts 2-point cone positioning to ensure the consistency of the printed pattern.

[0029] In this embodiment, the frame 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com