Bushing assembly of stabilizer rod and assembling method thereof

A stabilizer bushing and assembly method technology, which is applied to vehicle components, transportation and packaging, interconnection systems, etc., can solve problems such as easy noise, excessive wear, oil stains and muddy water erosion, etc., to improve life and avoid noise and the effects of excessive wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

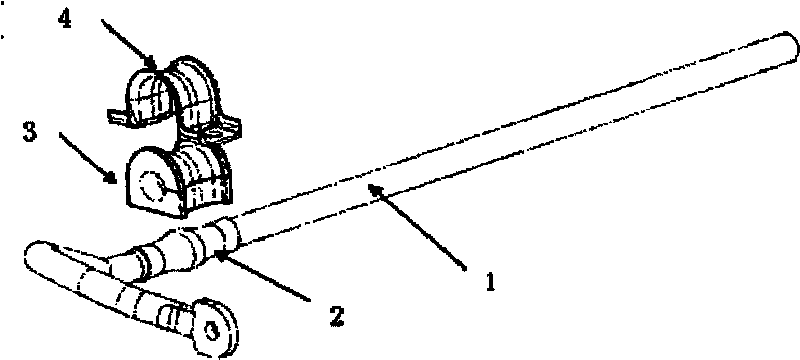

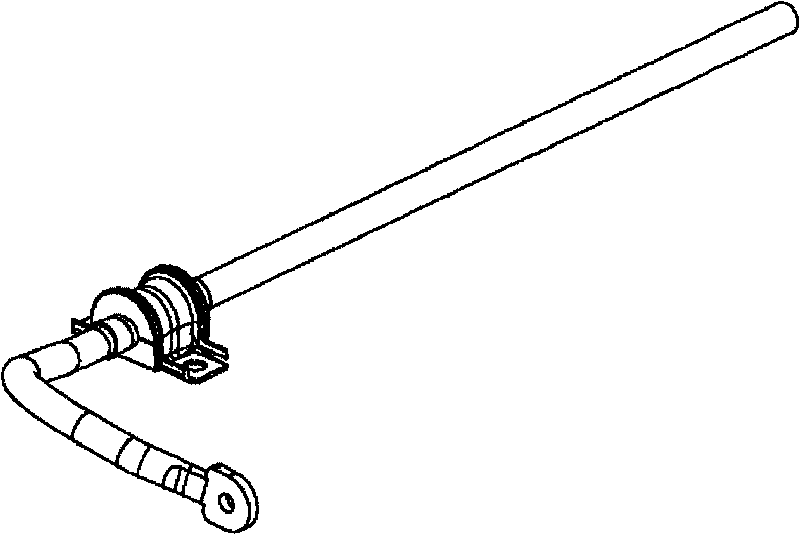

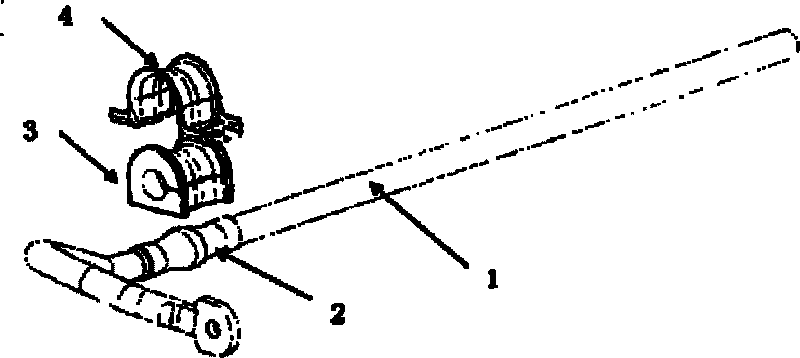

[0029] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

[0030] This embodiment is different from the previous method of adding limit rings on both sides or one side of the bush to limit the position, but by adding special-shaped injection molded parts on the stabilizer bar, the middle is large, the two ends are small, and the bush is connected with it. Cooperate to achieve the purpose of left and right limit. At the same time, oil dirt and muddy water are not easy to invade the inside of the bushing. Special-shaped injection molding parts are added to the stabilizer bar body. The middle is large and the ends are small. At the same time, the bushing with the same shape inside cooperates with it to form a closed limit structure, avoiding oily dirt and muddy water. pollution, thereby improving the service life of the bushing, and avoiding the ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com