A kind of polyester composition for preparing pipes and its preparation method and application

A composition, polyester technology, applied in applications, tubular articles, pipes, etc., can solve the problems of difficult extrusion of pipes, low melt strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

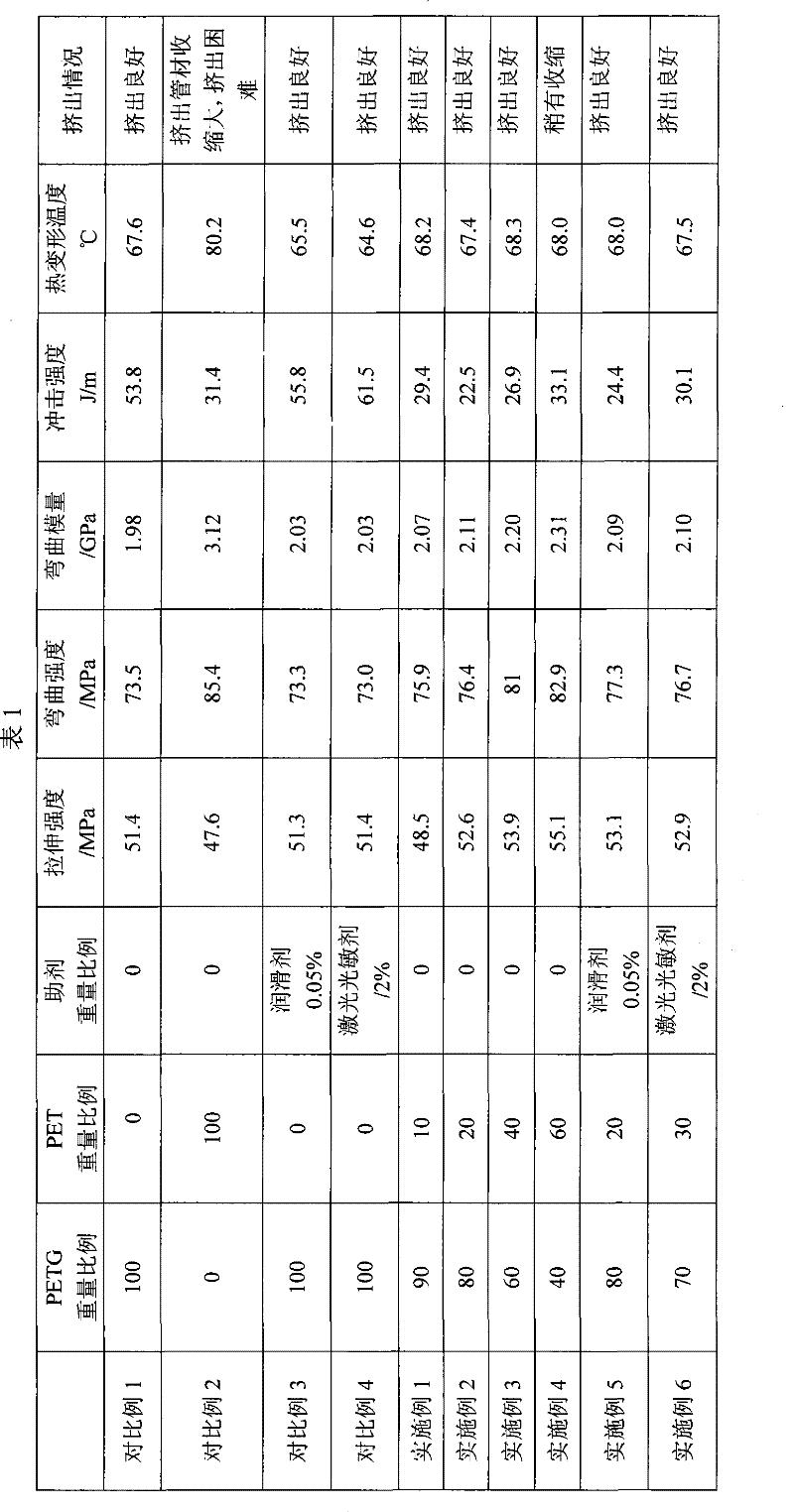

[0030] PET polyester (produced by Sinopec Yizheng Chemical Fiber Company, brand BG85), calculated by weight ratio: 10; PETG copolyester (produced by Malaysia EASMAN company, brand GN071) ratio is 90, antioxidant 1010 and 168 (Ciba Jing Chemical production, the ratio is 2:1) 0.1% by weight. The performance is shown in Table 1.

Embodiment 2

[0032] PET polyester (produced by Sinopec Yizheng Chemical Fiber Company, brand BG85), calculated by weight ratio: 20; PETG copolyester (produced by Malaysia EASMAN company, brand GN071) ratio is 80, antioxidant 1010 and 168 (Ciba Jing Chemical production, the ratio is 2:1) 0.1% by weight. The performance is shown in Table 1.

Embodiment 3

[0034] PET polyester (produced by Sinopec Yizheng Chemical Fiber Company, brand BG85), calculated by weight ratio: 40; PETG copolyester (produced by Malaysia EASMAN company, brand GN071) ratio is 60, antioxidant 1010 and 168 (Ciba Jing Chemical production, the ratio is 2:1) 0.1% by weight. The performance is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com