Technology for removing tar from raw gas containing coal tar

A technology of coal tar and crude gas, which is applied in the field of gas purification technology, can solve the problems of increasing enterprise investment and production costs, unfavorable environmental protection, etc., and achieve the effects of reducing production costs, saving production and operation costs, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

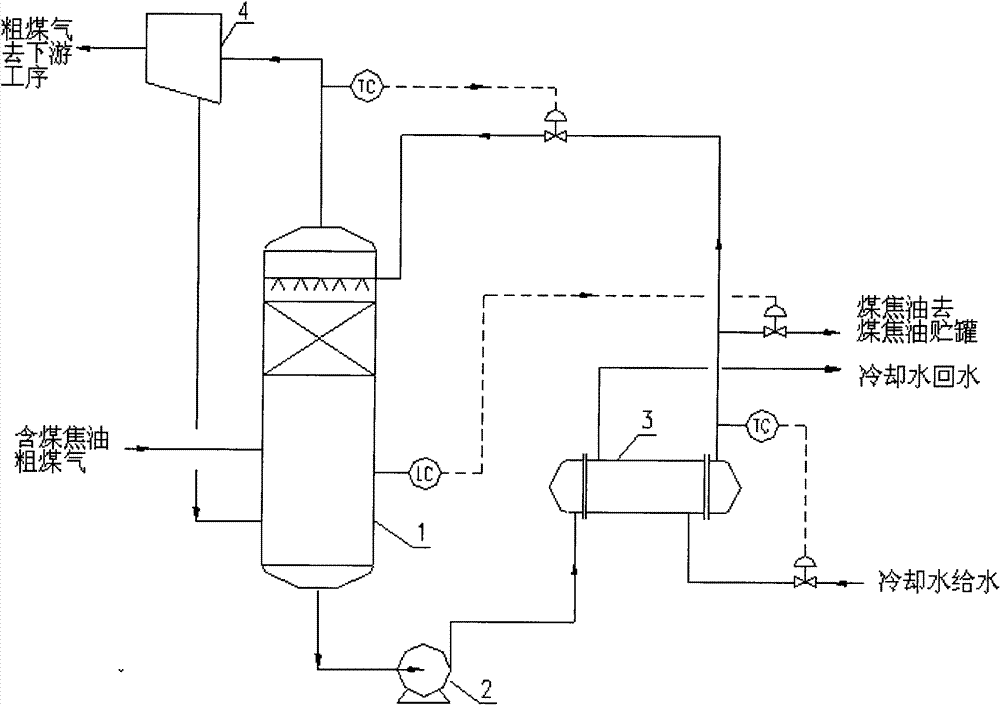

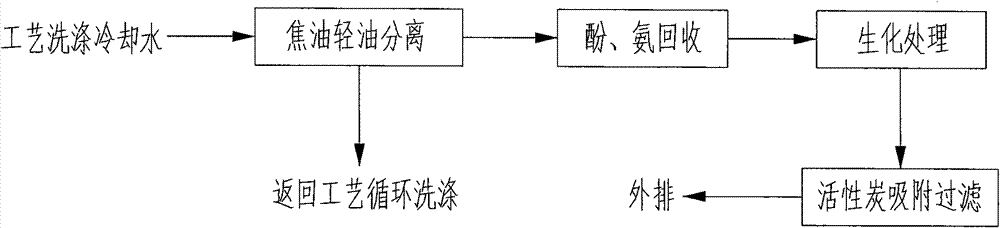

[0014] Embodiment: take the raw gas that low-temperature coking process produces as example, with reference to figure 1 , the tar-containing crude gas (about 361°C) produced in the low-temperature coking process enters the quenching tower 1, and is in countercurrent contact with the coal tar (about 71°C) circulating from the cooler 3, and the tar-containing crude gas is washed and cooled to 76-78 ℃ (in the present embodiment, the calculated dew point temperature is 73 ℃), wherein most of the coal tar dissolves in the coal tar that is circulated and sinks into the bottom of the quenching tower 1, and the crude gas after the initial tar removal is cooled by the quenching tower 1 The top of the tower enters the electric tar catcher 4, where almost all the coal tar in the crude gas is captured, and the captured coal tar flows back to the bottom of the quenching tower 1, and the crude gas from the electric tar catcher 4 is sent downstream Process: After the bottom of the chilling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com