Method for culturing coriolus versicolor and inducing oxalate decarboxylase by rice straw carbon source

A technology of oxalate decarboxylase and Coriolus versicolor, which is applied in the field of preparation of oxalate decarboxylase, can solve problems such as air pollution and increased greenhouse effect, and achieve the effects of easy operation, simple method and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

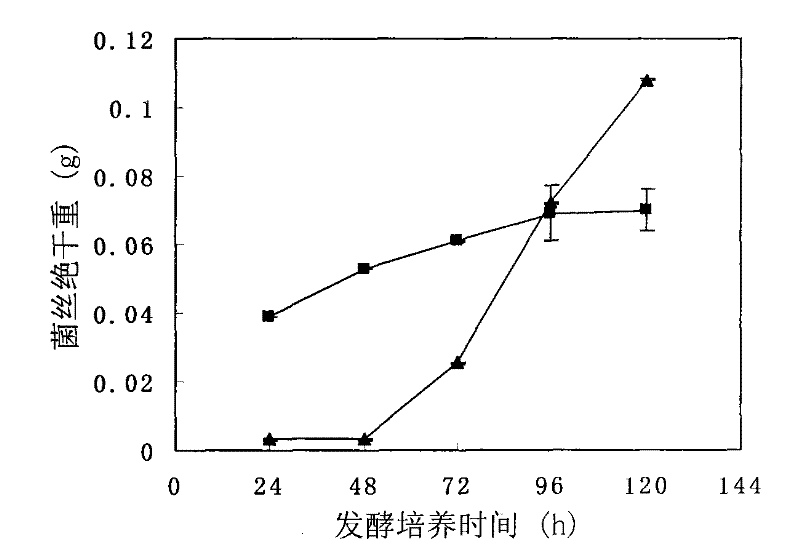

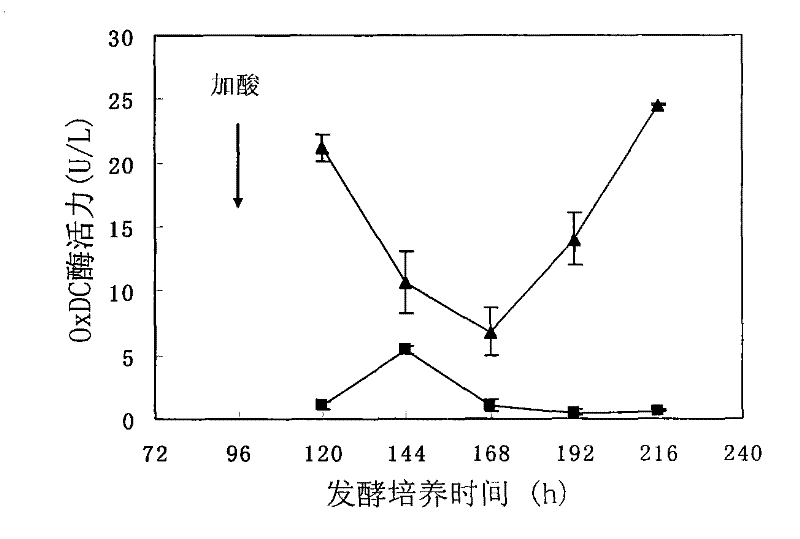

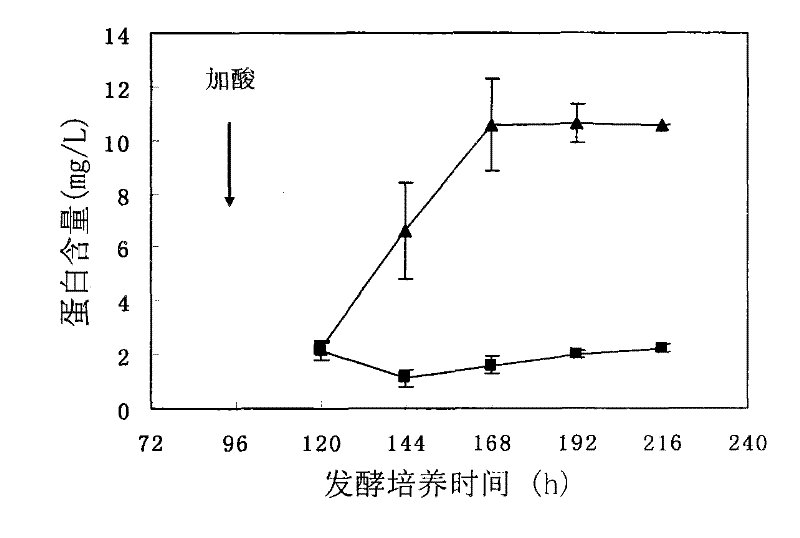

[0027] Production of Coriolus versicolor from rice straw hydrolyzate (the initial pH value of the medium is 5.0)

[0028] Weigh the fully ground rice straw, add a sulfuric acid solution with a concentration of 2% at a solid-to-liquid ratio of 1g: 12ml, soak the rice straw powder in a dilute sulfuric acid solution for 10 hours, place it in a high-pressure cooker, and heat it at 121°C , reacted for 30 minutes, filtered to remove the rice straw residue, and obtained the rice straw hydrolyzate for later use. The content of reducing sugar in rice straw hydrolyzate was determined by DNS method (glucose was used as standard sugar), and it was stored at 4°C for future use. Add rice straw hydrolyzate containing 1g reducing sugar (calculated as glucose) to every 50mL medium, then add 0.15g peptone, 0.05g potassium dihydrogen phosphate, 0.025g MgSO 4 ·7H 2 O, 0.01gNa 2 HPO 4 12H 2 O, and 50 μL of trace elements (the formula of trace elements is: FeSO 4 ·7H 2 O 10g / L, MnSO 4 ·H 2...

Embodiment 2

[0032] Production of Coriolus versicolor from rice straw hydrolyzate (the initial pH value of the medium is 5.0)

[0033] Weigh the fully ground rice straw, add a sulfuric acid solution with a concentration of 3% at a solid-to-liquid ratio of 1g:8ml, soak the rice straw powder in a dilute sulfuric acid solution for 10 hours, place it in a high-pressure cooking pot, and heat it at 150°C , reacted for 60 minutes, filtered to remove the rice straw residue, and obtained the rice straw hydrolyzate for later use. The content of reducing sugar in rice straw hydrolyzate was determined by DNS method (glucose was used as standard sugar), and it was stored at 4°C for future use. Add rice straw hydrolyzate containing 0.35g reducing sugar (calculated as glucose) to every 50mL medium, then add 0.15g peptone, 0.05g potassium dihydrogen phosphate, 0.025g MgSO 4 ·7H 2 O, 0.01gNa 2 HPO 4 12H 2 O, and 50 μL of trace elements (the formula of trace elements is: FeSO 4 ·7H 2 O 10g / L, MnSO 4...

Embodiment 3

[0036] Production of Coriolus versicolor from rice straw hydrolyzate (the initial pH value of the medium is 5.0)

[0037] Weigh the fully ground rice straw, add a sulfuric acid solution with a concentration of 3% at a solid-to-liquid ratio of 1g: 15ml, soak the rice straw powder in a dilute sulfuric acid solution for 10 hours, place it in a high-pressure cooker, and heat it at 100°C , reacted for 60 minutes, filtered to remove the rice straw residue, and obtained the rice straw hydrolyzate for later use. The content of reducing sugar in rice straw hydrolyzate was determined by DNS method (glucose was used as standard sugar), and it was stored at 4°C for future use. Add rice straw hydrolyzate containing 1.5g reducing sugar (calculated as glucose) to every 50mL medium, then add 0.15g peptone, 0.05g potassium dihydrogen phosphate, 0.025g MgSO 4 ·7H 2 O, 0.01gNa 2 HPO 4 12H 2 O, and 50 μL of trace elements (the formula of trace elements is: FeSO 4 ·7H 2 O 10g / L, MnSO 4 ·H ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com