Gas bubble pump with gas bubble collecting device

A collection device and bubble pump technology, applied in the direction of pump, liquid variable capacity machinery, machine/engine, etc., can solve the problems of low-quality unstable heat source, low efficiency, unstable work, etc., to expand the scope of heat source utilization, The effect of reducing energy loss and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail, but present embodiment is not intended to limit the present invention, and every adopt similar structure of the present invention and similar change thereof, all should be included in the protection scope of the present invention.

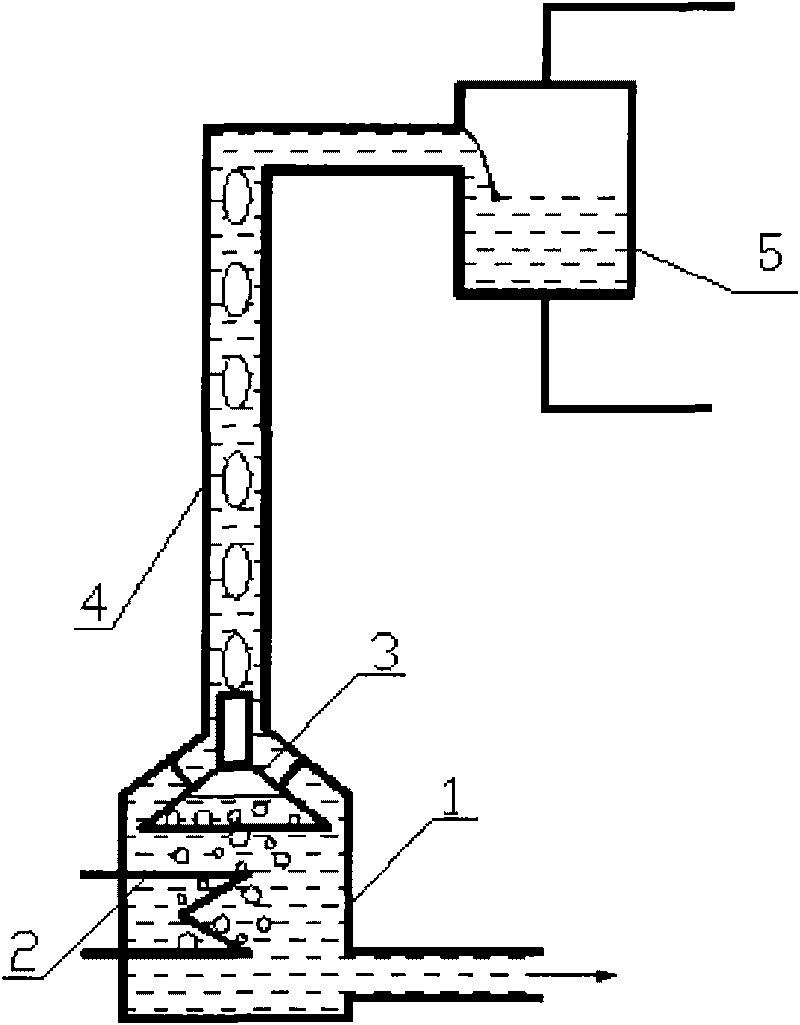

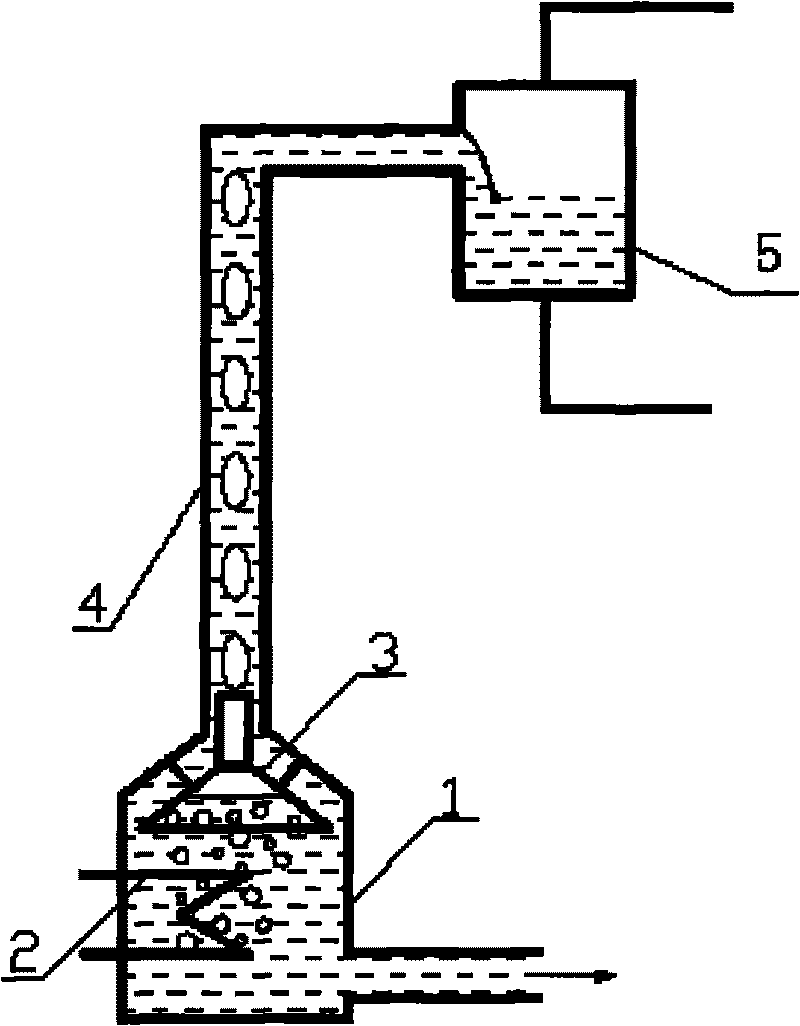

[0021] A bubble pump with a bubble trap, such as figure 1 As shown, it includes a riser 4, a bubble collection device 3 and a low-level liquid reservoir 1. The lower part of the bubble pump riser 4 is connected to the low-level liquid reservoir 1, and the low-level liquid reservoir 1 is connected to the generator. The low-level liquid reservoir 1 A heat exchanger 2 is arranged inside, and the heat exchanger 2 is connected to an external heat source. Above the heat exchanger 2, a bubble collecting device 3 is connected at a position perpendicular to the heat exchanger. The upper part of the low-level liquid reservoir 1 has a fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com