Draw bail of vane wheel and high-speed rotation shaft of high-speed centrifugal compression device

A technology of compression equipment and high-speed centrifugation, applied in mechanical equipment, rigid shaft couplings, components of pumping devices for elastic fluids, etc., can solve the problem of reducing the aerodynamic performance of the impeller, breaking the dynamic balance state of the high-speed rotor, and affecting the rotor Problems such as running stability, to achieve the effect of ensuring aerodynamic performance and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

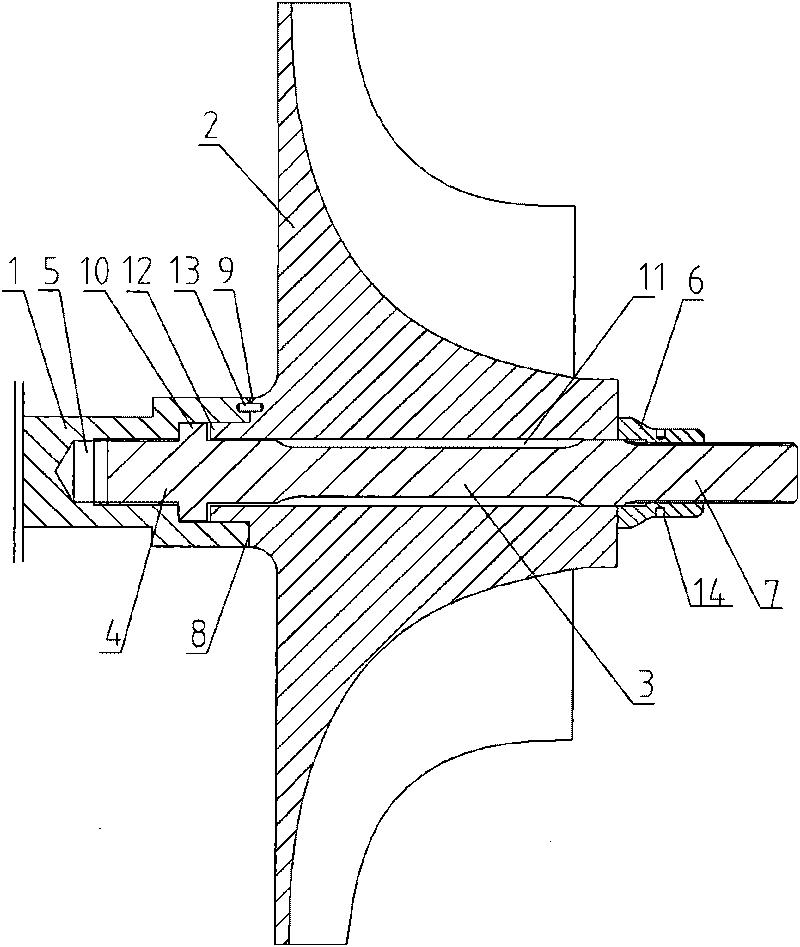

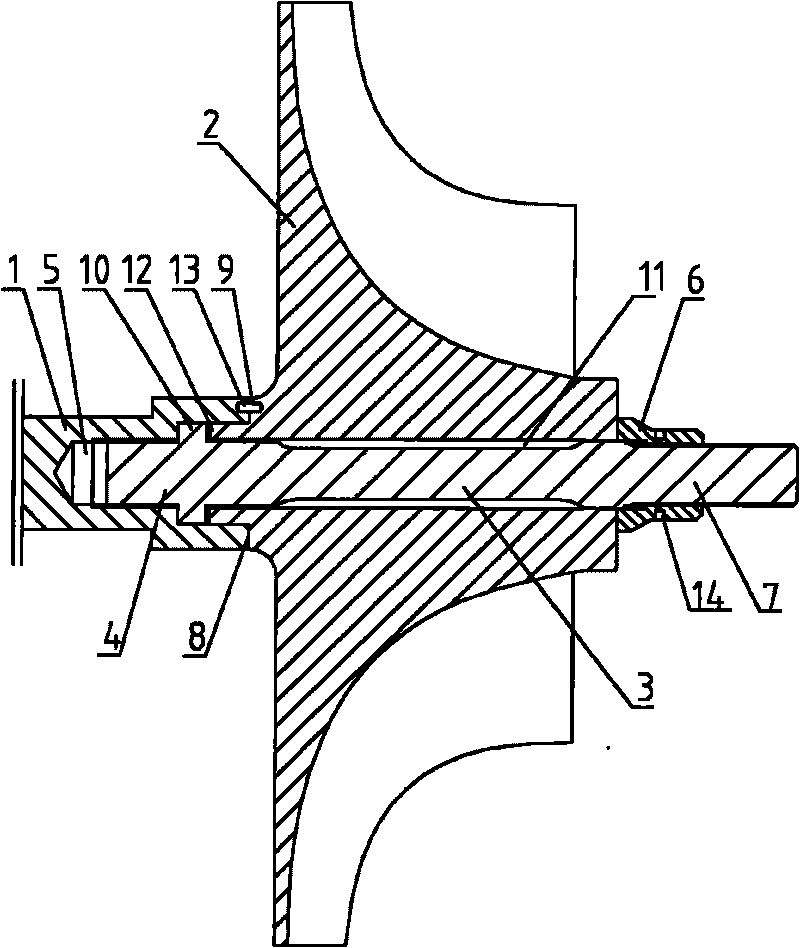

[0008] See figure 1 , the present invention includes a high-speed rotating shaft 1, an impeller 2, a stretching shaft 3 that runs through the center hole 11 of the impeller 2, one end 4 of the stretching shaft is threadedly connected to an internal threaded hole 5 at the end of the high-speed rotating shaft 1, and a compression nut 6 is set in the stretching shaft. The other end 7 of the shaft, the end face 8 of the high-speed rotating shaft is fastened to the outstretched journal 9 of the impeller 2, the end face of one end of the compression nut 6 is tightly connected to the end face of the impeller 2; Installed in the outer raised part 12 of the center hole 11, the end surface 8 of the high-speed rotating shaft has an inner hole, and the outwardly extending journal 9 of the impeller 2 is fastened to the inner hole of the end surface 8 of the high-speed rotating shaft through the positioning pin 13; Have turning hole 14.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com