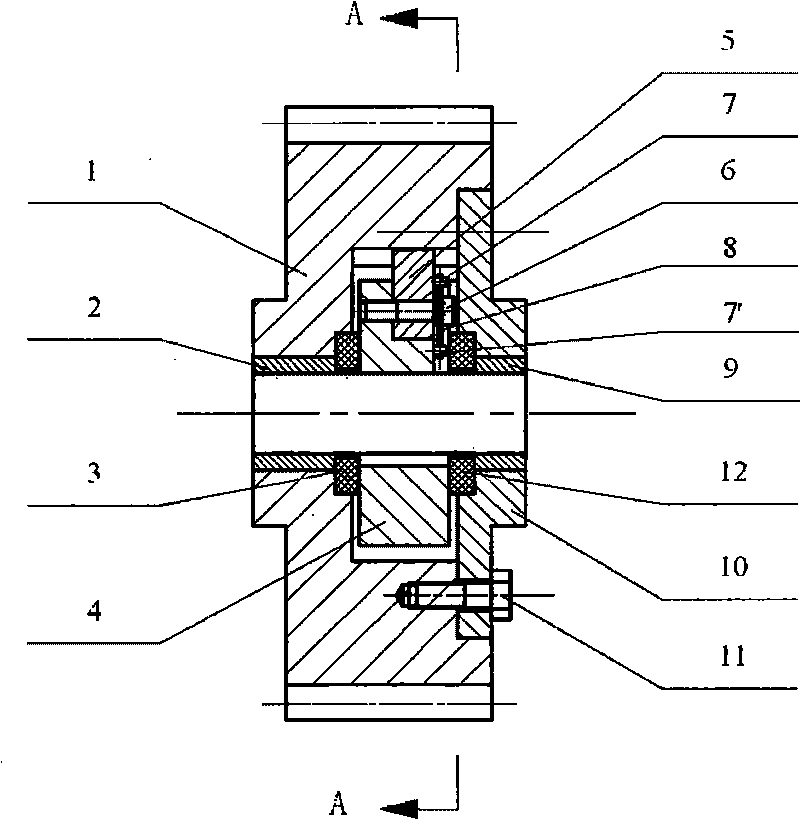

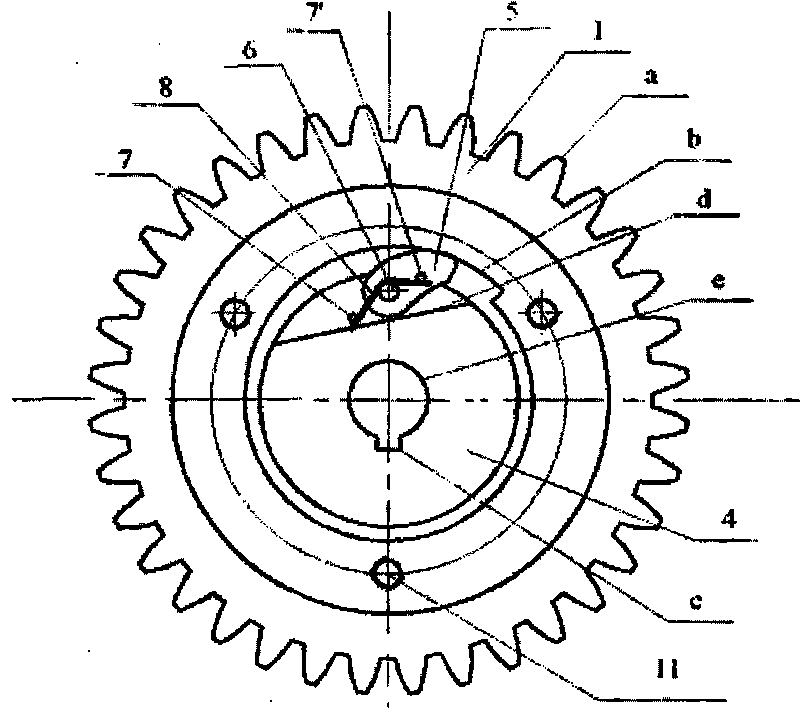

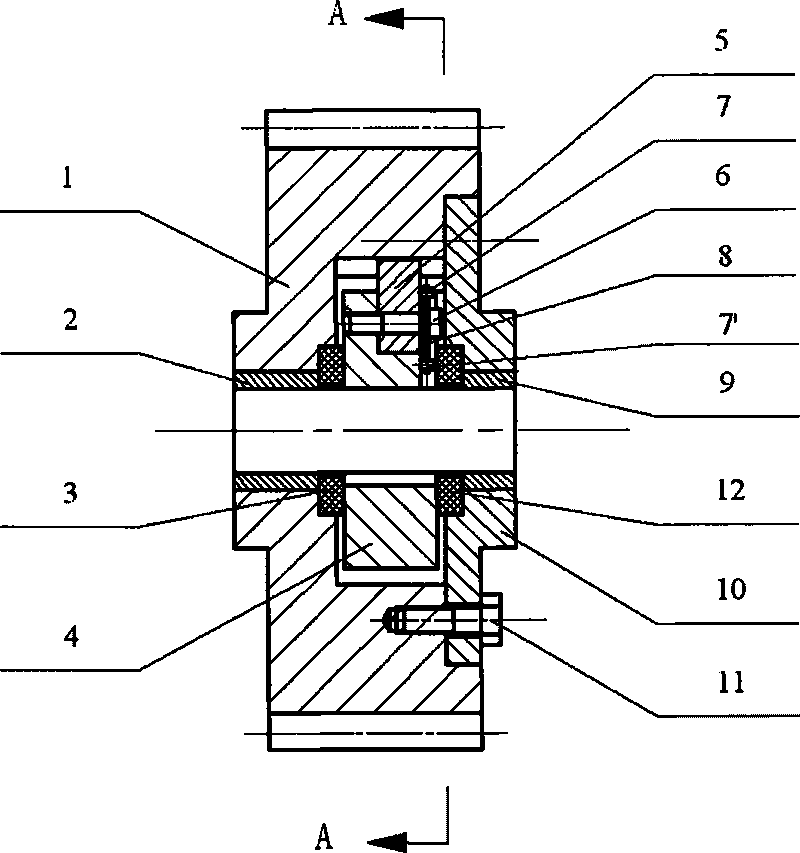

Unidirectional transmission device integrated with ratchet gear

A technology of transmission device and ratchet gear, which is applied in the field of mechanical transmission parts, can solve the problems of decreased motion accuracy, bloated transmission mechanism, and poor structural compactness, and achieves the effects of stable performance, compact structure, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The specific implementation of the present invention will be described in detail in conjunction with the accompanying drawings and technical solutions. When the ratchet-gear integrated one-way transmission device is used, the gear device is installed on the transmission shaft. The left bush 2 and the right bush 9 are made of anti-friction materials, such as ceramics, polytetrafluoroethylene, etc., which have two functions: one is to reduce the friction and wear when the transmission shaft and the gear 1 move relative to each other; Replacing the bushing can increase the life of the gear unit. A left retaining ring 3 is installed inside the gear 1, and anti-friction material is used to avoid the direct contact between the driving wheel 4 and the gear 1, and reduce the friction and wear of the end face. The right retaining ring 12 installed on the end cover 10 also uses anti-friction material to reduce the friction and wear of the driving wheel 4 and the end cover 10, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com