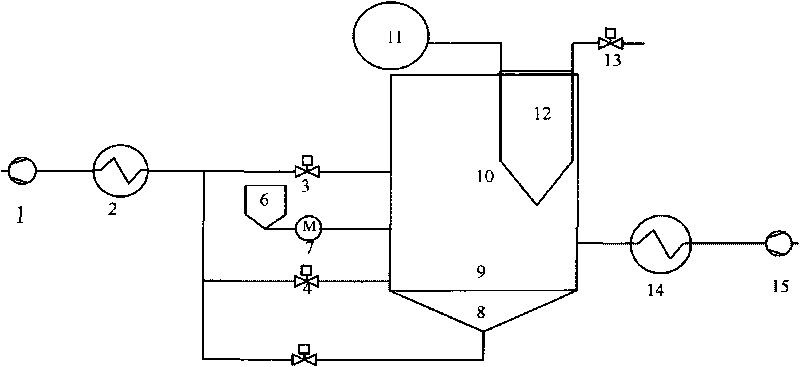

Method for controlling load of biomass vibration grate boiler

A technology of boiler load and vibrating grate, which is applied in the control of combustion, lighting and heating equipment, etc., can solve the problems of unstable boiler fuel properties, difficulty in maintaining stable boiler load, and difficulty in automatic control of unit stable operation load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

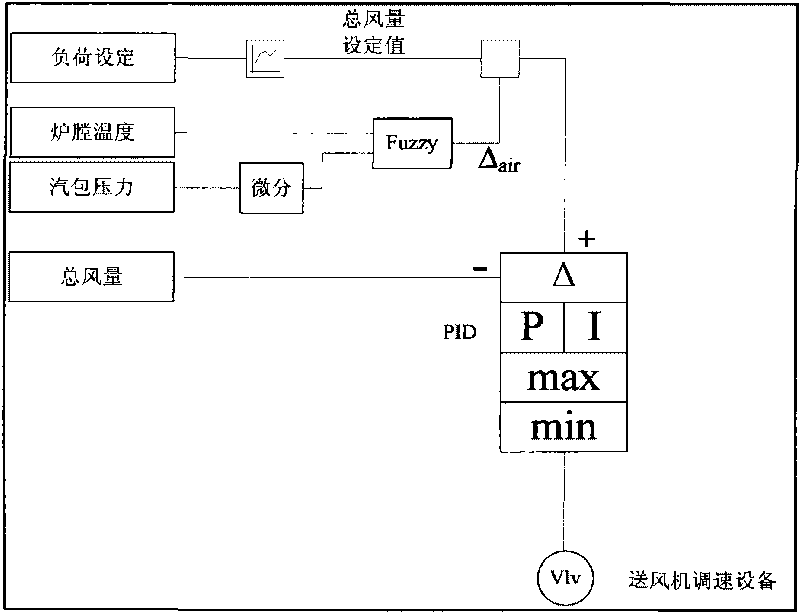

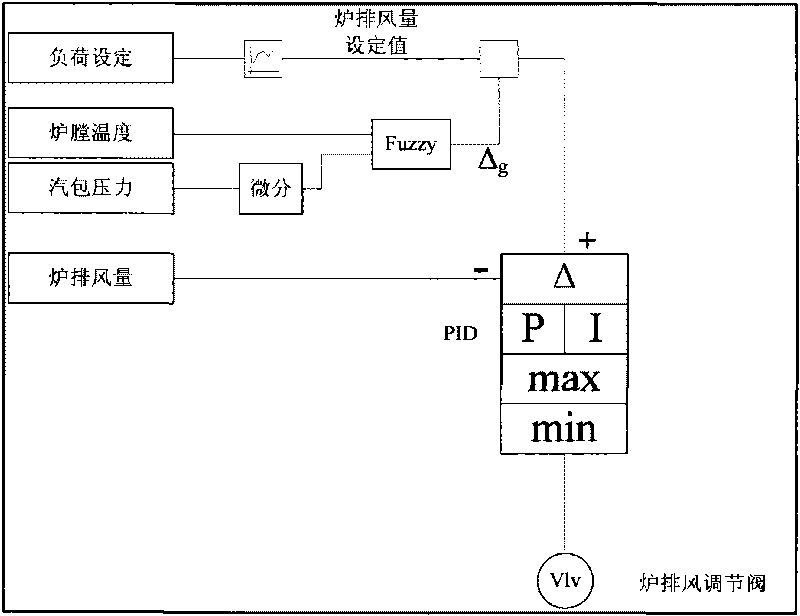

[0045] Based on the above model analysis of boiler load and furnace temperature, we found that due to the strong randomness of changes in the moisture and calorific value of biomass fuel, the fluctuation of boiler load is unpredictable and difficult to control accurately. Therefore, consider Introduce fuzzy control scheme to solve it.

[0046] It can be seen from the model analysis that to overcome the fluctuation of boiler load, it is mainly to effectively control the heat input into the boiler. When the load and furnace temperature drop, on the one hand, it is necessary to increase the temperature of each air as much as possible, and on the other hand, it is necessary to increase the amount of boiler fuel B r , keep the grate real-time fuel volume B g , to increase the fuel reaction rate coefficient k B . The way to maintain the real-time fuel volume is to maintain the dynamic balance between the feed volume and the slag discharge volume, which can be accomplished through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com