Truck carrying saddle binding face stress detection analytical device

A technology of analyzing device and bearing saddle, which is applied to measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problems of undetectable contact surface between bearing saddle and bearing, traffic accidents, truck safety accidents, etc., to avoid Effects of major railway transport accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

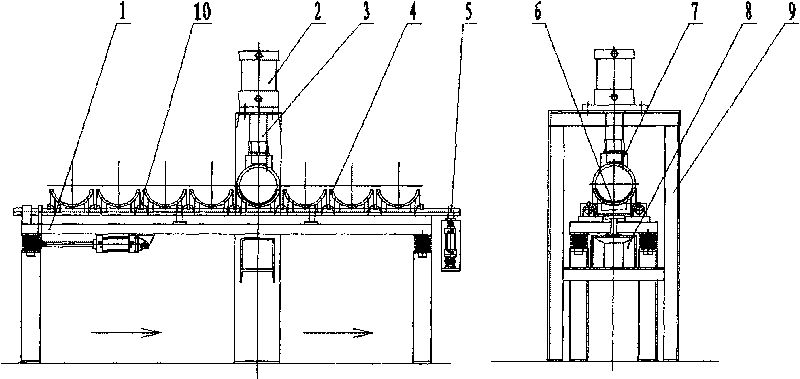

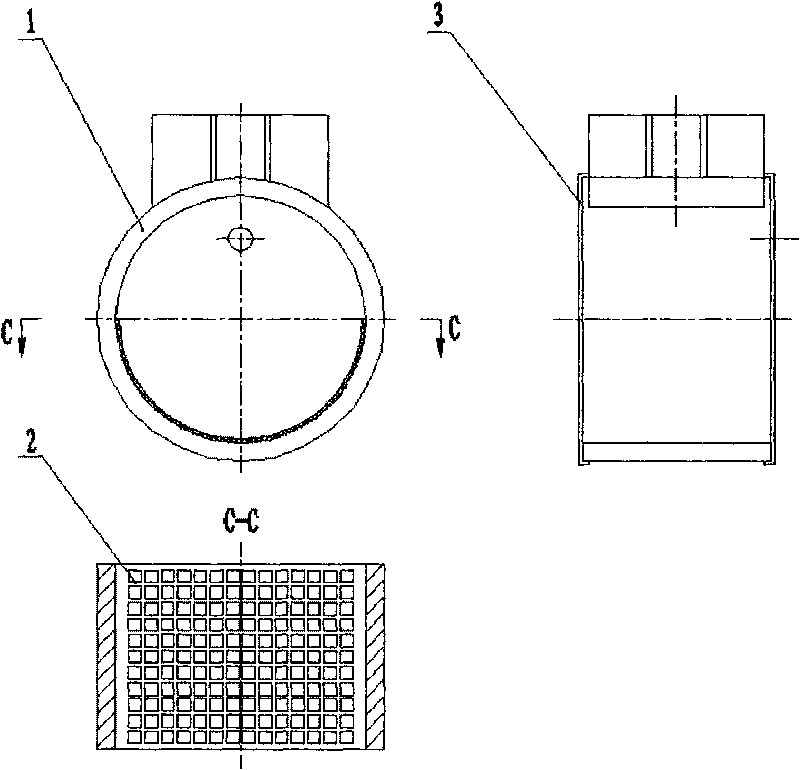

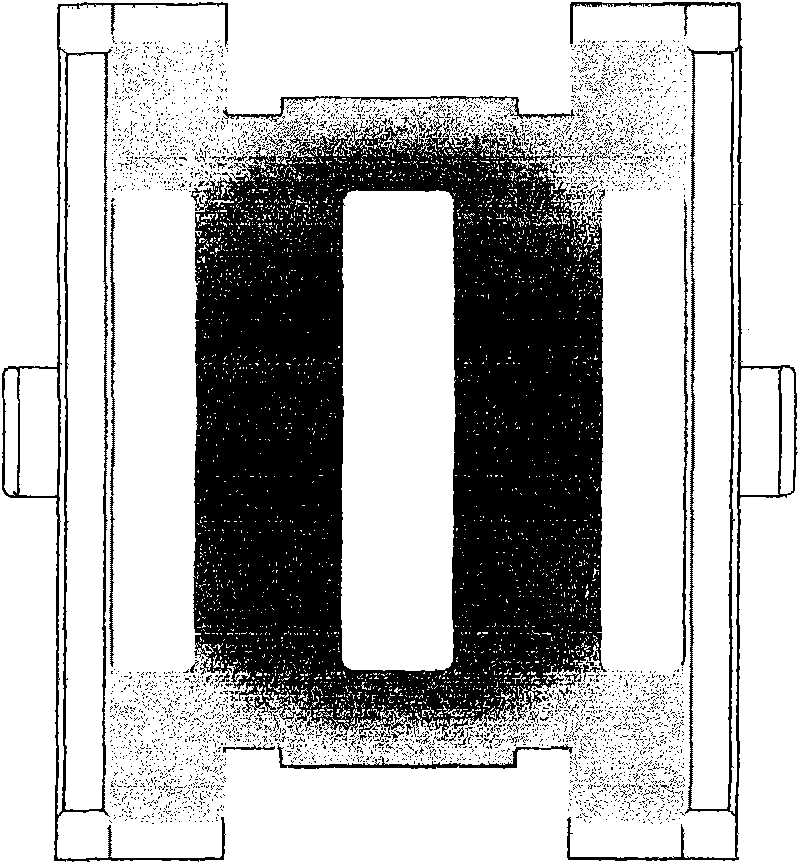

[0010] The specific implementation of the utility model is: the loading and unloading transmission station transmits the bearing saddle to the detection station in turn, and can transmit the detected bearing saddle out; the detection station has a contact surface with the bearing saddle The detection tire; the detection tire is in the shape of a simulated bearing shell, with a dot matrix distributed pressure sensor on the position in contact with the bearing saddle; above the detection station, there is a pressure acting rod that can apply different pressures, and the pressure acting rod can directly act on the Pressure is applied on the bearing saddle; the pressure action rod is driven by hydraulic pressure, the pressure can be automatically set and adjusted according to the requirements of the process, and the maximum pressure can reach 12.5 tons; the pressure sensor is set near the detection station. The signal detected by the sensor is transmitted to the upper computer for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com