Large-scale direct shear apparatus between geo-technic synthetic materials and between geo-technic synthetic materials and earth

A technology of geosynthetics and direct shear instrument, which is applied in the field of direct shear test, can solve the problem of invariable, unguaranteed shear area, inability to conduct direct shear test between geosynthetics and soil and geosynthetics at the same time problems such as the direct shear test to achieve the effect of increasing the utilization rate, light weight and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

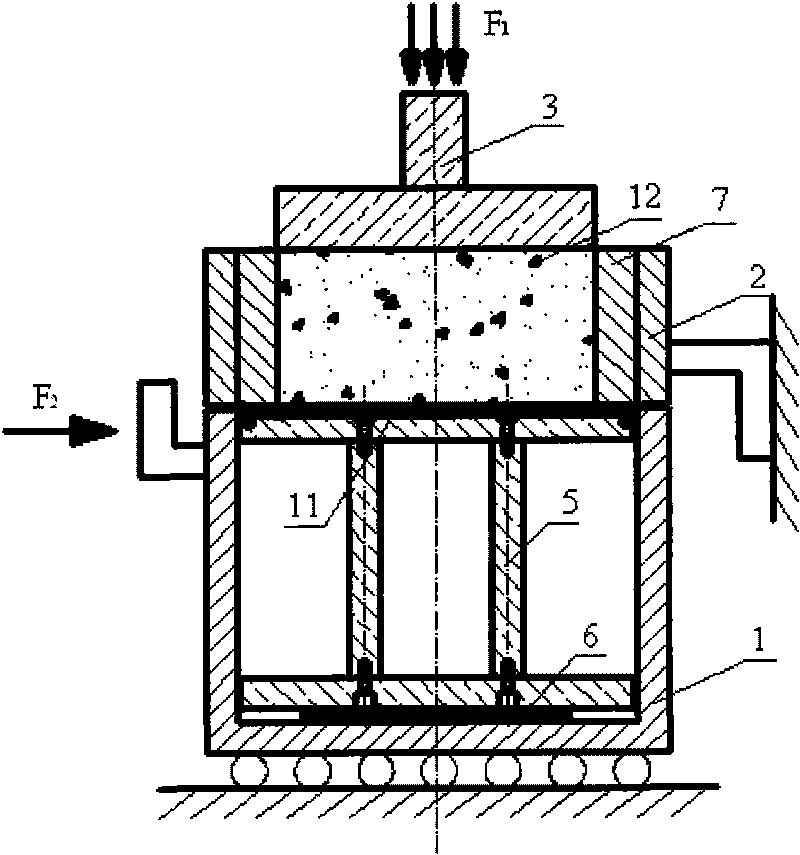

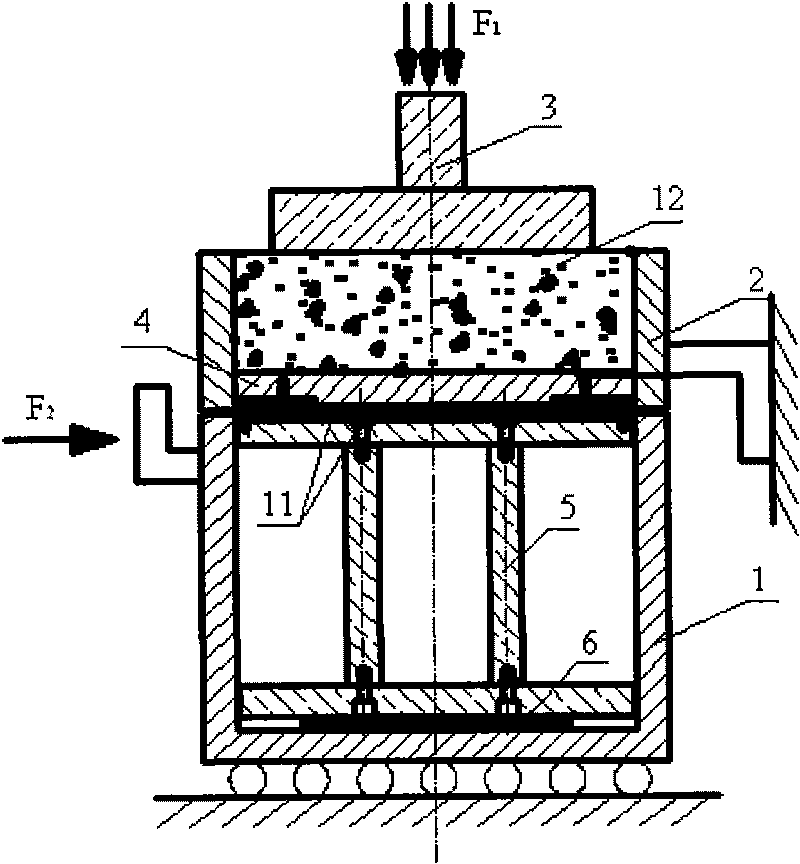

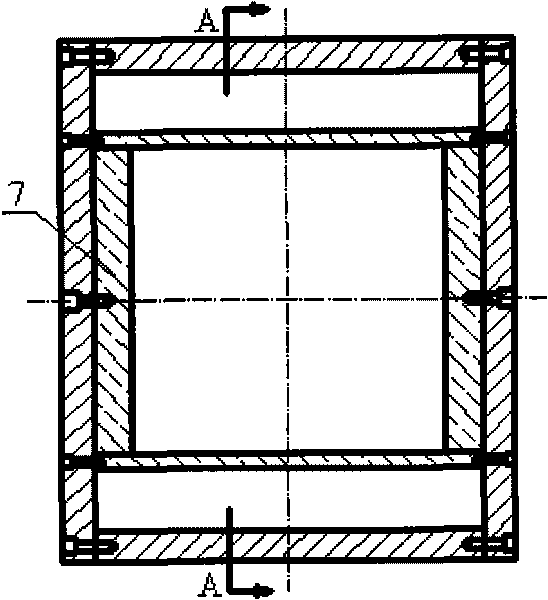

[0034] A preferred embodiment of the present invention is described as follows in conjunction with accompanying drawing: figure 1 As shown, the large-scale direct shear instrument between geosynthetics and geosynthetics-soil includes the lower shear box 1, the upper shear box 2 and the pressure transmission plate 3, the upper shear box 2 and the lower shear box 1 The center line is aligned, and the periphery of the pressure transmission plate 3 is matched with the inner periphery of the upper shear box 2; a "II"-shaped plate frame 5 is placed in the lower shear box 1, below the "II"-shaped plate frame 5, Stainless steel gaskets 6 of different thicknesses and quantities can be placed according to the height of the test material. figure 1 Shown, " II " font plate frame 5 is slightly smaller than the size in the lower shear box, and this is for the convenience of " II " font plate frame in and out. see figure 1 , the height of the "II"-shaped plate frame 5 is 8mm lower than the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com