Light guide plate, backlight module, liquid crystal display device and electric equipment

A technology of liquid crystal display and backlight module, which is applied in mechanical equipment, lighting devices, lighting and heating equipment, etc., and can solve problems such as labor-intensive assembly hours and poor fitting of hooks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

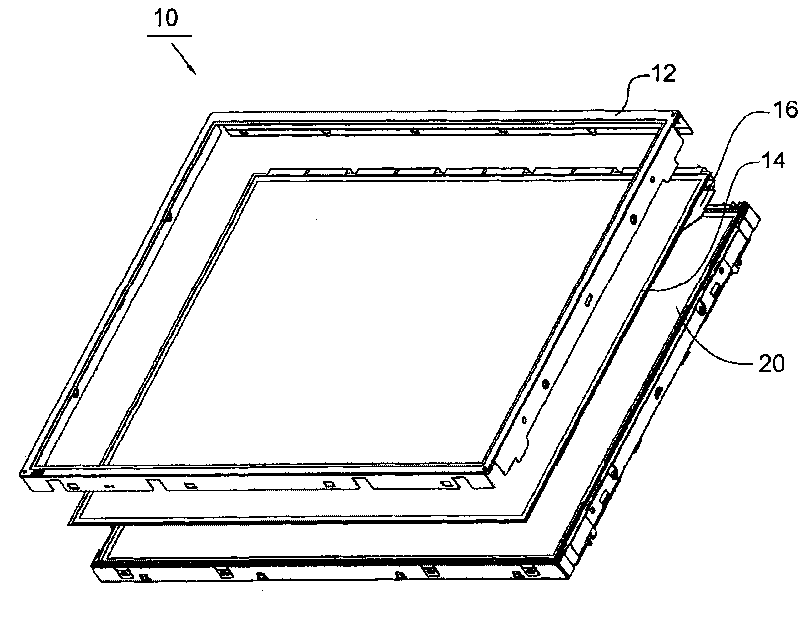

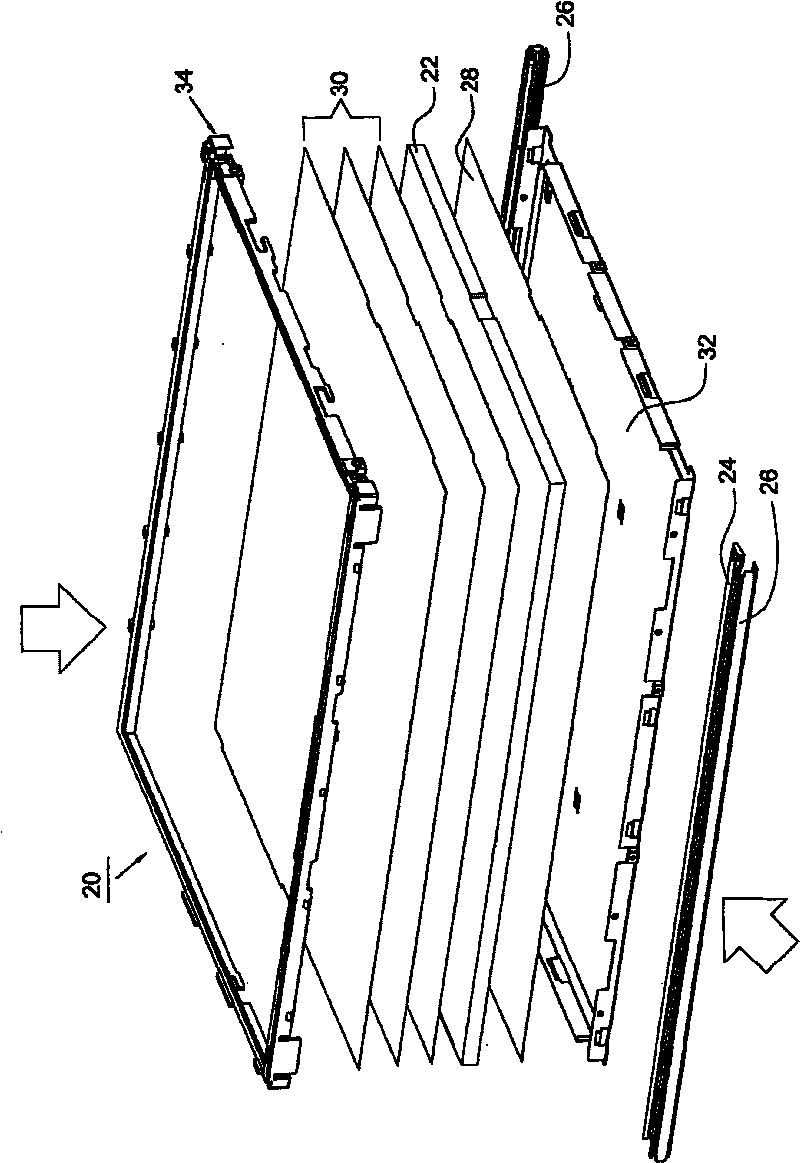

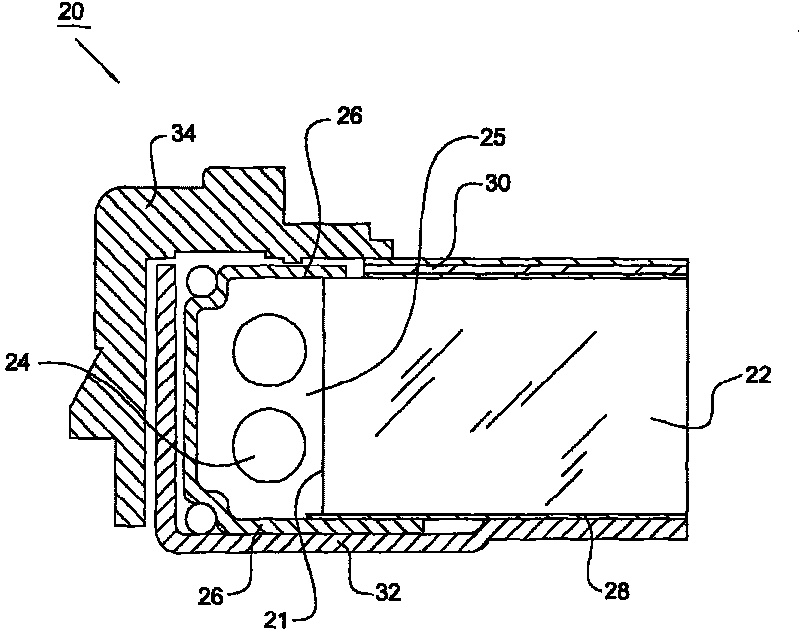

[0058] refer to Figure 4 and5 , which shows a backlight module 120 according to an embodiment of the present invention. The backlight module 120 includes a light guide plate 122 , a light source unit 124 , an optical film set 130 and a reflector 128 . The light guide plate 122 has a top surface 150 , a first bottom surface 152 , two first side surfaces 154 and two first side surfaces 156 . The first bottom surface 152 is opposite to the top surface 150 , and the two first side surfaces 154 and the two first side surfaces 156 are connected to the top surface 150 and the first bottom surface 152 .

[0059] The light guide plate 122 includes a first accommodating space 163 disposed on the top surface 150 for fixing a liquid crystal panel. The first accommodating space 163 includes four second sides 164b, a first opening 164a and a second bottom surface 164c, wherein the second side 164b connects the top surface 150 and the second bottom surface 164c, and the second side 164b i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com