Silicon controlled rectifier and manufacturing method thereof

A silicon-controlled rectifier and doped region technology, applied in semiconductor/solid-state device manufacturing, electrical components, thyristors, etc., can solve the problems of difficult control of the trigger voltage value, increase the difficulty of the designer's design, etc., to reduce the design cost and ESD protection. The effect of improving the ability and reducing the trigger voltage value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A silicon controlled rectifier according to the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

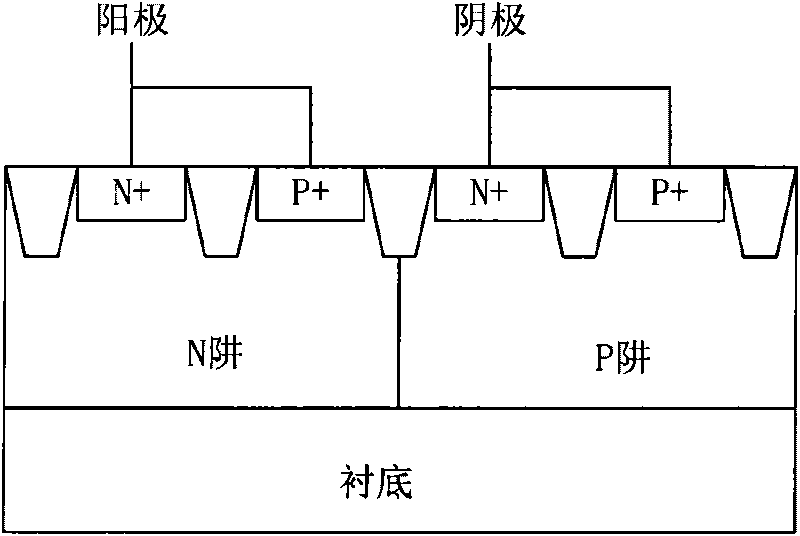

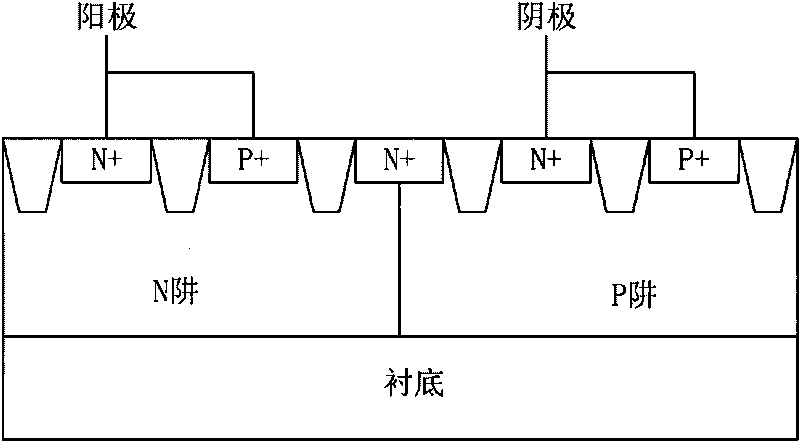

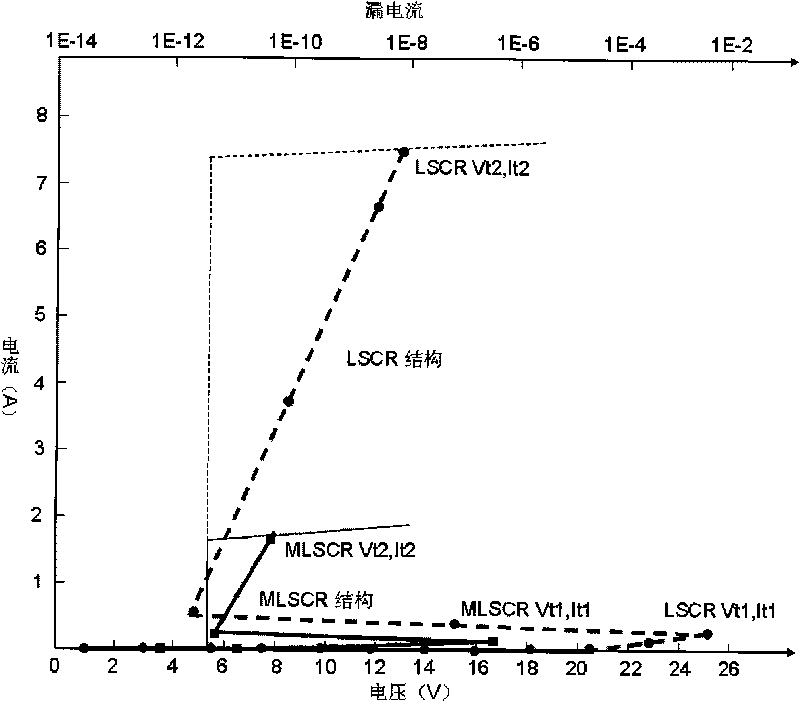

[0030] Such as figure 1 , 2 As shown in and 3, for example, the traditional lateral silicon-controlled rectifier LSCR structure and the improved lateral silicon-controlled rectifier MLSCR (Modified LSCR) in a certain process of 0.18 μm are taken as an example, because the traditional LSCR has a higher trigger voltage value, see image 3 In Vt1, the trigger voltage value is related to the breakdown voltage value of the N well Nwell / P well Pwell, and Vt1 is about 25V. Such a trigger voltage prevents the silicon controlled rectifier from being turned on in time during the ESD discharge process to effectively protect the internal The circuit cannot play a good role in protecting the device. At the same time, its secondary breakdown current value is about 7A, which is relatively high.

[0031...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com