Main shaft anti-reversal device in zipper teeth chain continuous making machine

A zipper element and manufacturing machine technology, applied in the directions of sliding fastener elements, applications, fasteners, etc., can solve the problem of inability to correctly manufacture zipper element chain belts, etc., and achieve the effect of easy micro-adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

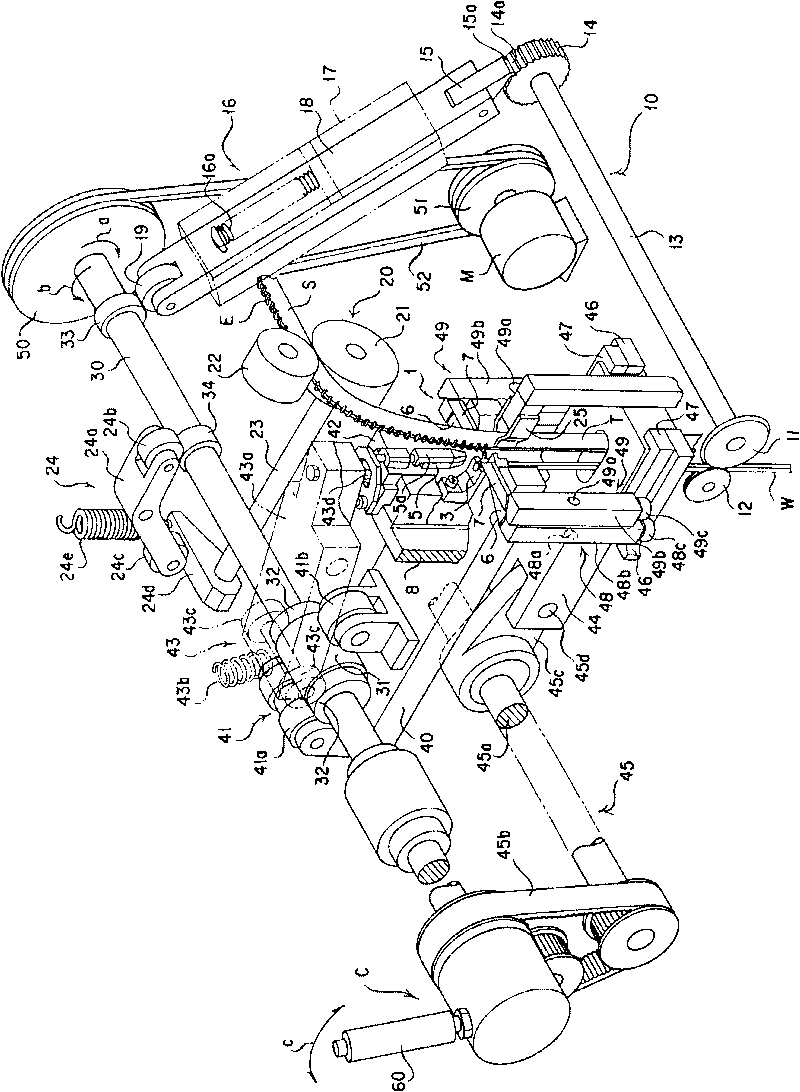

[0056] The structure of the main part of the fastener stringer continuous manufacturing machine of this invention is demonstrated.

[0057] Such as figure 1 As shown, the zipper stringer continuous manufacturing machine of the present invention has: a forming implantation part 1 for engaging elements; a feeder of the engaging element metal wire W that is intermittently fed to the forming implanting part 1 The apparatus 10; the fastener tape supply device 20 for intermittently supplying the fastener tape T to the above-mentioned molded implant part 1 by sending out the fastener stringer S; and the main shaft 30 rotationally driven by a motor.

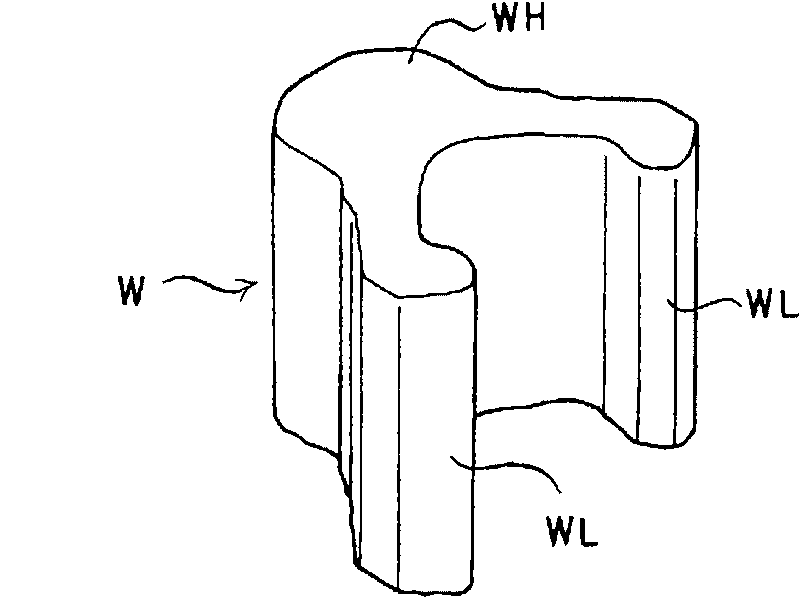

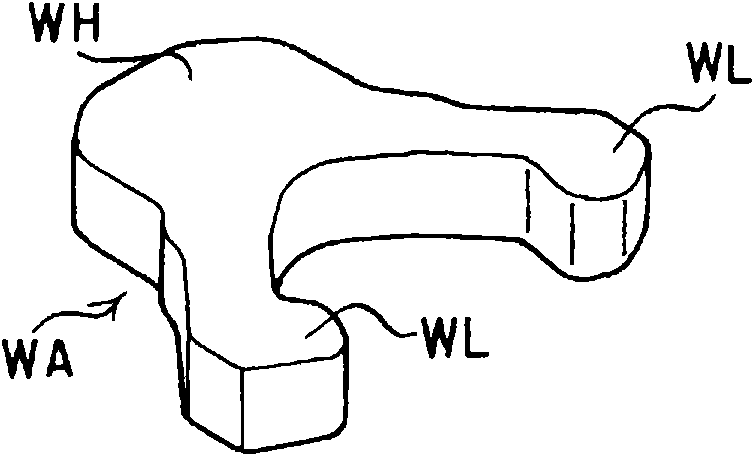

[0058] Such as figure 2 As shown, the metal wire W for engaging elements is a vertically long material having a head WH and a pair of legs WL, and has a substantially Y-shaped cross section.

[0059] Such as figure 1 and Figure 6 As shown, the forming implant part 1 of the above-mentioned engaging element has: a cutting device, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com