Agitating method and agitating machine for porcelain powder agitator

A technology of mixers and mixers, which is applied to mixers with rotating mixing devices, cement mixing devices, chemical instruments and methods, etc., can solve problems such as power failure, poor bonding force, and difficulty in discharging materials, and achieve reduced rotation The effect of reducing resistance, increasing stirring torque, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The stirring method of a porcelain powder mixer and the stirrer used in the present invention will be further described in detail in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation of the present invention.

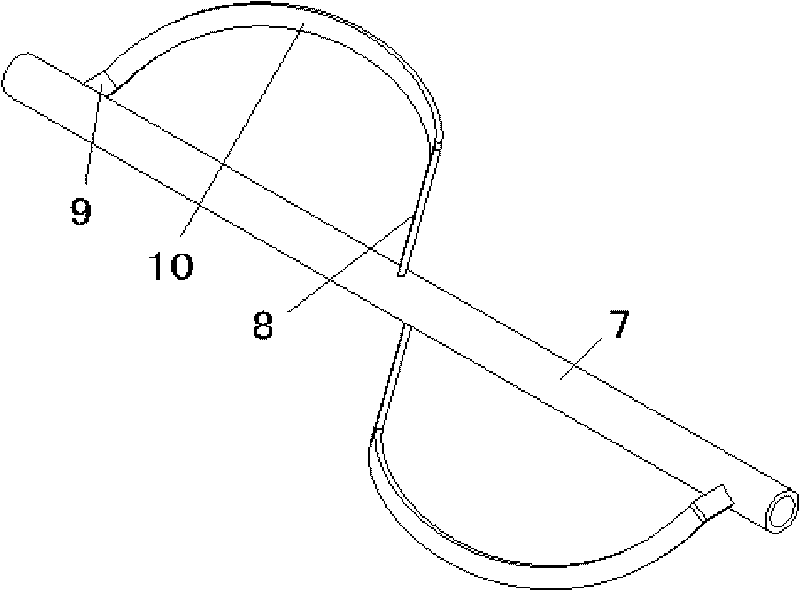

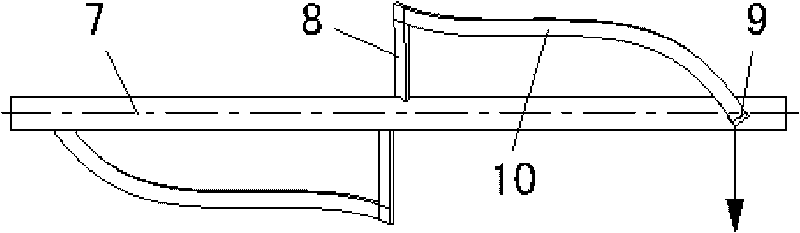

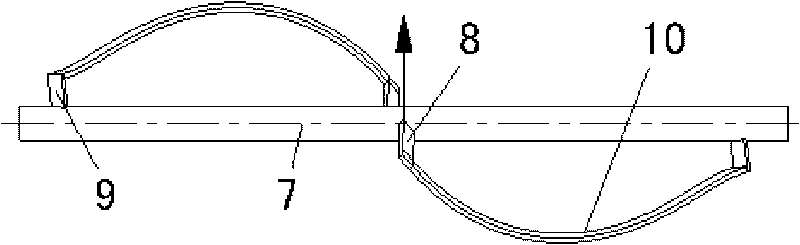

[0023] Example. A kind of mixing method of porcelain powder mixer of the present invention, as Figure 1 ~ Figure 4 shown. The method adopts a small angle of attack double-helix stirrer to stir the porcelain powder; the angle of attack refers to the angle between the plane of the blade and the direction of rotation (the direction of the arrow in the figure is the direction of rotation of the blade) , when the plane of the blade is parallel to the direction of rotation, it is 0°, and when the plane of the blade is perpendicular to the direction of rotation, it is 90°; the stirring shaft sleeve of the stirrer is driven by the stirring shaft on the mixer, and two sets of helical blades are welded on the sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com