Impinging stream micro-channel reactor and application

A micro-channel reactor, micro-channel technology, applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical processes, etc. Achieving highly uniform results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The content and implementation method of the present invention will be described below in conjunction with the accompanying drawings.

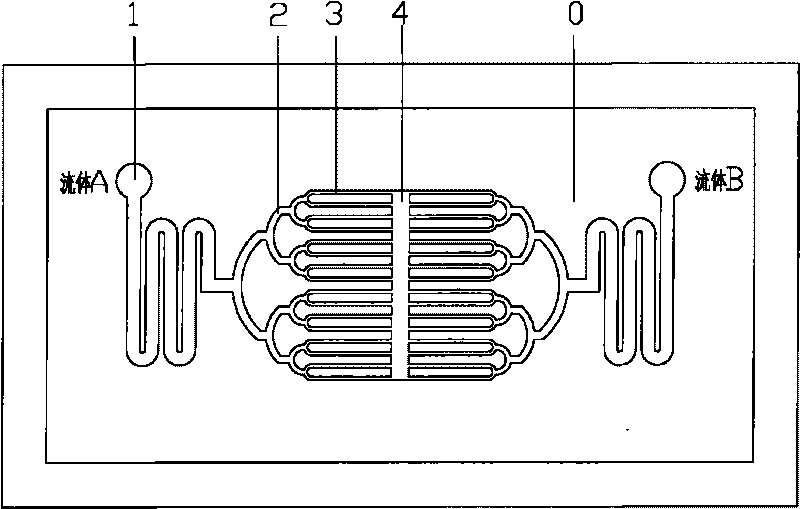

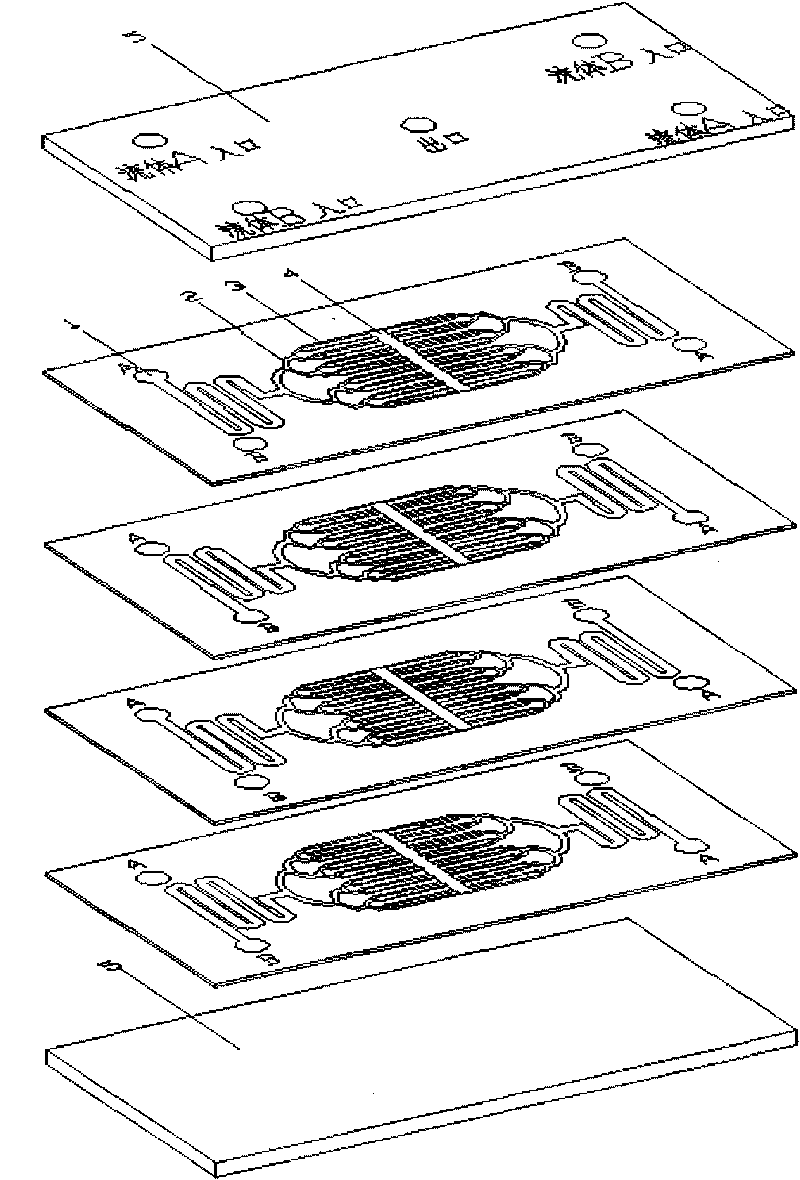

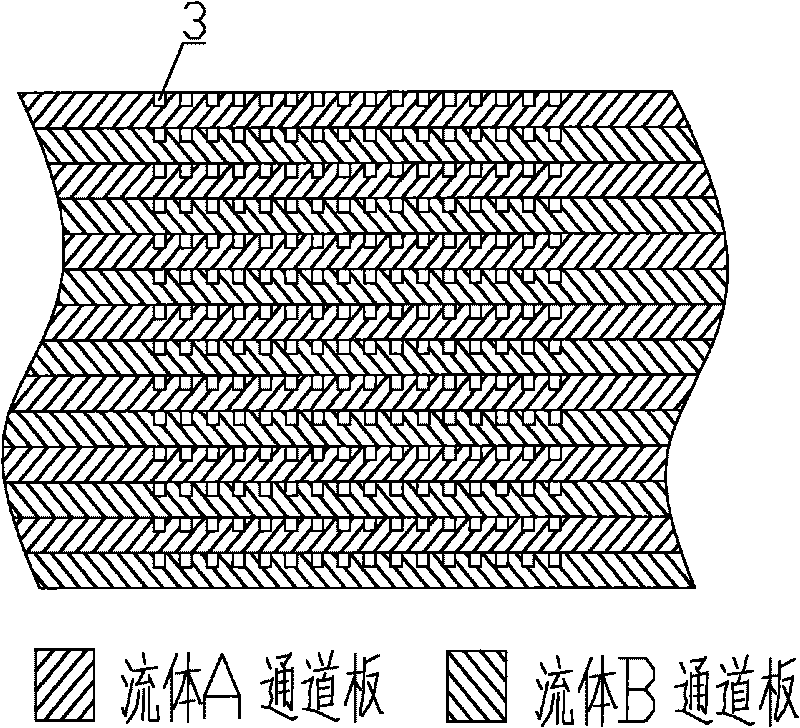

[0020] like figure 1 Shown in and 2, the reactor of the present invention comprises at least one plate chip 0 and two cover plates (i.e. sealing plates) 5 that contain microchannels; The longitudinal microchannel 4 or microporous channel is the impact area; one or more transverse microchannels 3 are symmetrically engraved on the left and right sides of the impact area, and the transverse microchannel is connected with the impact area. Fluid inlets connected to the microchannels are respectively arranged at the ends; fluid outlets are arranged on the sealing plate corresponding to the chip impact area, and fluid inlets of the sealing plate are arranged corresponding to the fluid inlets on the chip; chip interaction Stacked between two sealed flat plates, pressed together to form an impingement flow microchannel reactor,

[0021] There ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydraulic diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com