Manufacturing method of concave-roller type thermal straightening machine supporting roller

A manufacturing method and technology for supporting rollers, which are applied in the directions of forming tools, manufacturing tools, instruments, etc., can solve the problems of increasing the middle wear and flattening the middle, reducing the degree of local wear and the amount of local deformation, etc. The effect of flattening defects and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

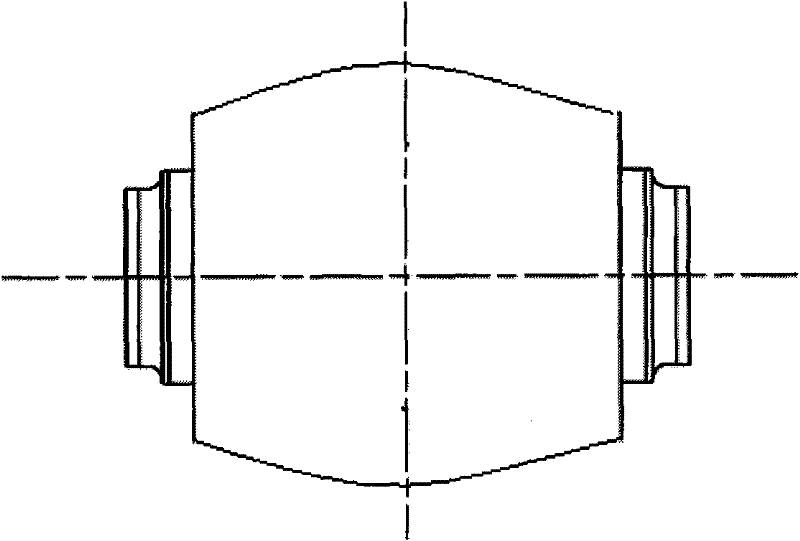

[0021] A concave roll type hot straightening machine support roll, see Figure 5 , the support roll of the concave roll type thermal straightening machine includes a roll body 1, and the roll body 1 is a concave curved surface 2 adapted to the total deformation after coupling of contact mechanical deformation and thermal deformation. The diameter of the roll body 1 is the smallest at the central part, and the diameter at the ends on both sides is the largest.

[0022] A method for manufacturing a support roll of a concave roll type heat straightening machine, the method is carried out according to the following procedures:

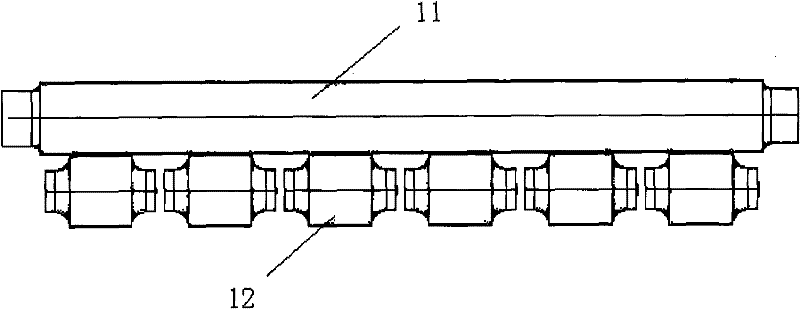

[0023] 1) Establish the straightening roll-backing roll finite element structure model comprising straightening roll 11 and flat roll type backing roll 12; see figure 1 .

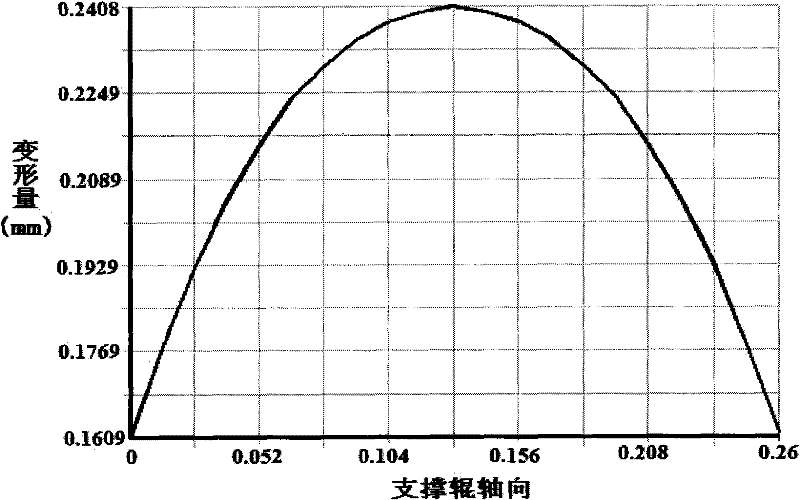

[0024] 2) According to the contact pressure, mechanical deformation, heat conduction, temperature field, thermal deformation and thermal-mechanical coupling deformation of the straigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com