Turning tool cutter row device of combined working machine tool of milling machine

A compound processing and tool array technology, applied in the direction of tool holders, etc., can solve the problems of inability to realize automatic clamping and tool changing of turning tools, reduce the production efficiency of milling and turning machine tools, and affect the degree of automation of milling and turning machine tools. , to achieve the effect of easy disassembly and assembly, simple and unique positioning method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

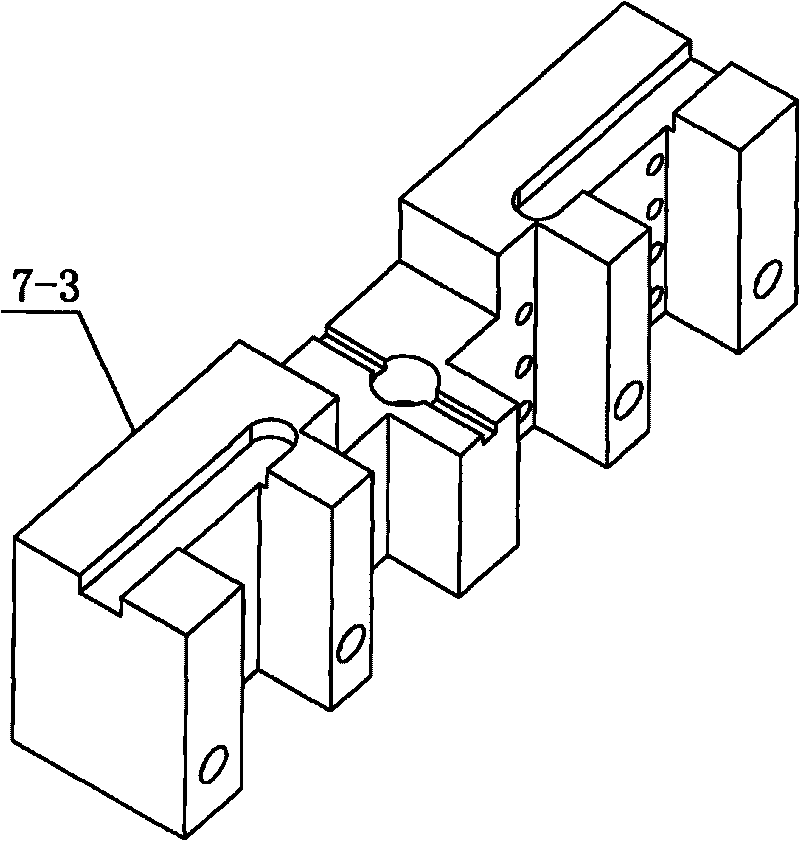

[0007] Specific implementation mode one:, as Figure 3-5 As shown, the turning tool row device of the milling and turning compound processing machine tool described in this embodiment includes a tool row locator 7-1, a knife handle 7-2 and a tool row main body 7-3, and the tool row locator 7-1 The profile is cylindrical, the profile of the knife handle 7-2 is conical, and the knife row main body 7-3 has four vertical grooves 7-3-1 on the side along the length direction, and the four vertical grooves 7-3-1 is used to place four turning tools for processing the outer circle, and a knife hole 7 is opened on the same side of the knife row main body 7-3 on both sides of the vertical groove 7-3-1 at the end -3-2, four knife holes 7-3-2 are used to place four turning tools for processing inner holes; knife handle 7-2 is arranged on the middle part of the upper end surface of knife row main body 7-3, and knife handle 7-2 The large end of the blade is connected to the upper end surfac...

specific Embodiment approach 2

[0009] Specific implementation mode two: as Figure 3-5 As shown, the turning tool row device 7 of this embodiment also includes two positioning keys 7-4, and a positioning keyway 7-3-3 is respectively opened on the two ends of the upper end surface of the tool row main body 7-3, and the tool row positioning The lower end face of device 7-1 is connected with the upper end face of knife row main body 7-3 by the positioning key 7-4 that is contained in the positioning key groove 7-3-3. The positioning keyway 7-3-3 is parallel to the Y-axis (sliding saddle 1) of the machine tool. Through the contact between the upper end surface of the 7-4 positioning key and the bottom surface of the 7-1 upper keyway, the impact force of turning on the milling spindle is reduced, thereby prolonging the service life of the milling machine spindle. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

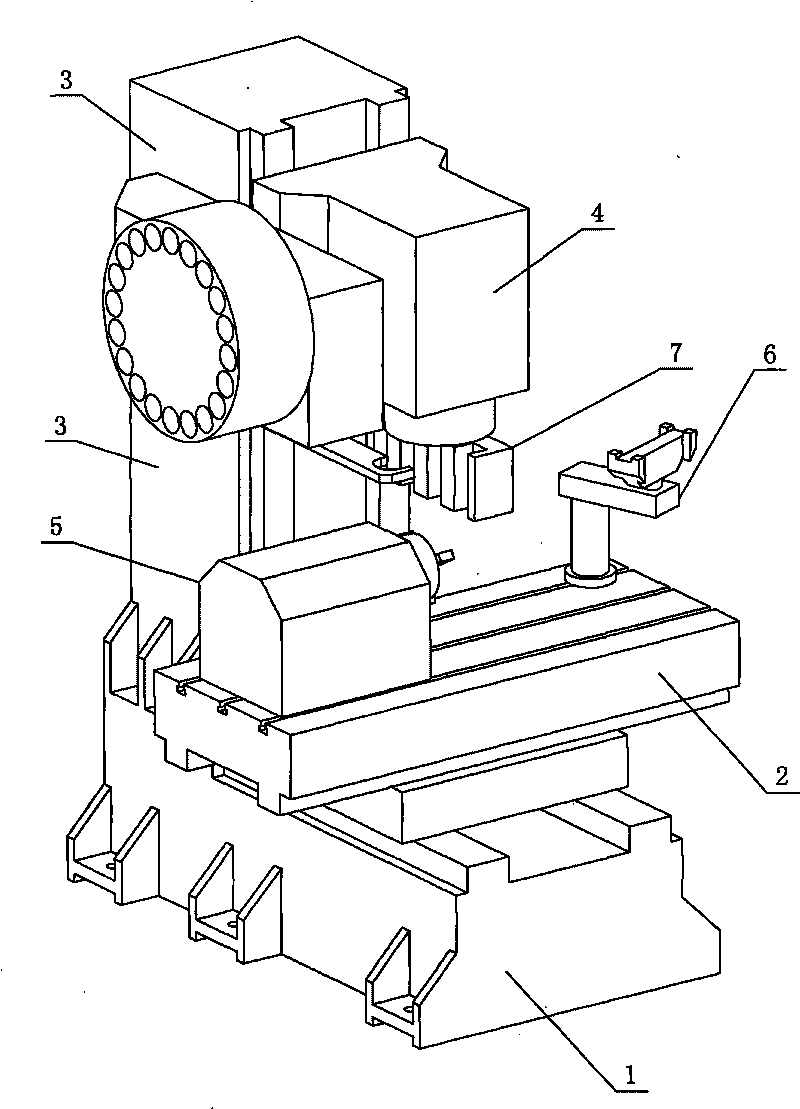

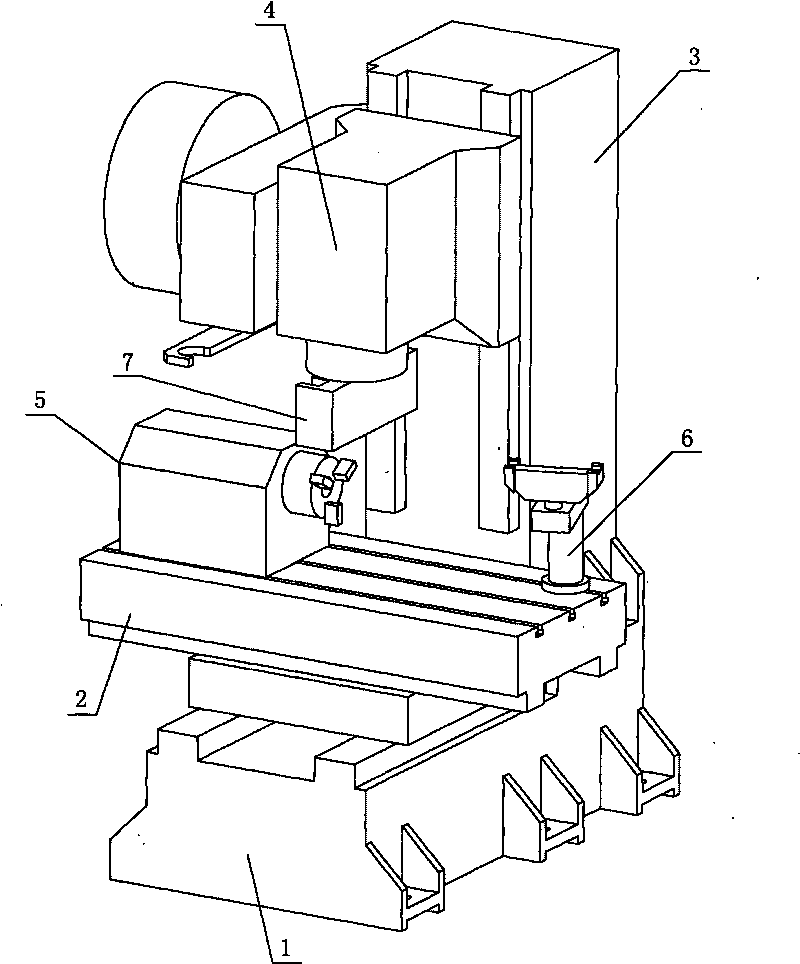

[0010] Specific implementation mode three: as Figure 1~2 As shown, the present embodiment is equipped with the milling-turning compound processing machine tool of the present invention, and the compound processing machine tool comprises a milling machine main body, and the milling machine main body comprises a saddle 1, a workbench 2, a column 3 and a headstock 4, and the workbench 2 Horizontally located above the saddle 1 and the two are arranged in a cross shape, the column 3 is located at the rear end of the table 2 and the lower end of the column 3 is connected to the saddle 1, the headstock 4 is located above the table 2 and the headstock 4 is connected to the column 3 sliding connection; the compound processing machine tool also includes a lathe spindle assembly 5, a lathe tool changing mechanism 6 and a turning tool row device 7, the lathe spindle assembly 5 is arranged on the left end of the workbench 2 and is slidably connected with the workbench 2, The lathe tool ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com