Laser welding device

A technology of laser welding and laser beam welding, applied in the field of devices used for welding, can solve the problems of limitation, easy generation of welding pores X-rays, pollution of the structure and size of the weld seam, etc., so as to reduce the volume and density, and eliminate the laser welding pores. , Increase the effect of weld penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

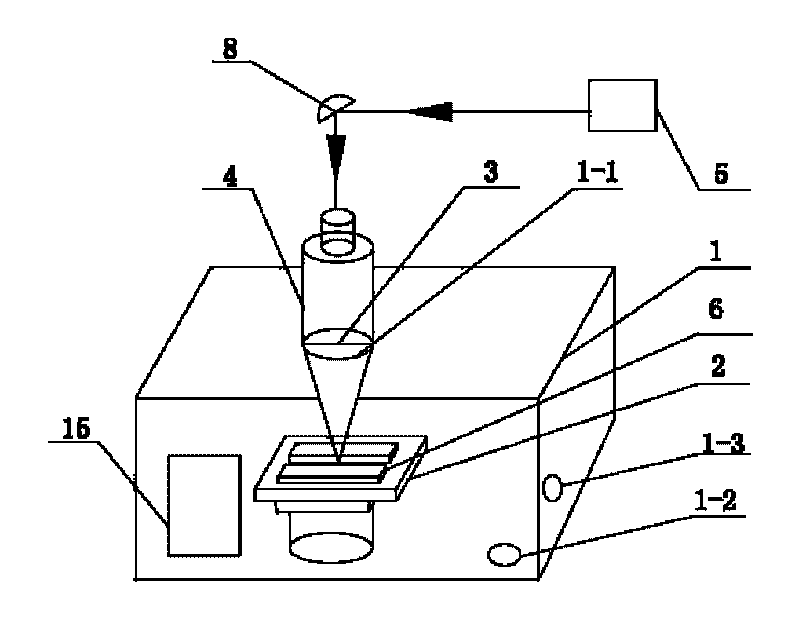

[0010] Specific implementation mode one: combine figure 1 Describe this embodiment, the device of this embodiment comprises workbench 2, focusing lens 3, laser beam welding torch head 4, laser 5 and at least one reflector 8, the light that described laser 5 outputs is reflected to by at least one reflector 8. In the laser input port of the laser beam welding gun head 4, the device also includes a vacuum chamber 1, the workbench 2 is installed in the vacuum chamber 1, and the upper wall of the vacuum chamber 1 is provided with a first through hole 1-1 , and the first through hole 1-1 is set corresponding to the workbench 2, the workpiece 6 is set on the workbench 2, and the head of the laser beam welding torch head 4 passes through the first through hole 1-1 and is set in a vacuum In the chamber 1, the laser beam welding gun head 4 is airtightly connected with the first through hole 1-1, the focusing lens 3 is installed in the laser beam welding gun head 4 and the focusing lens...

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 Describe this embodiment, the laser 5 of this embodiment is CO2 laser, YAG laser, semiconductor laser or fiber laser, wherein the model of fiber laser is IPGYLR-20000 or IPGYLR-5000, CO 2 The model of the laser is DC030, the model of the YAG laser is HL2006D, DP020HX or DS 015HQ, and the model of the semiconductor laser is DL-028Q or DL-031Q. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

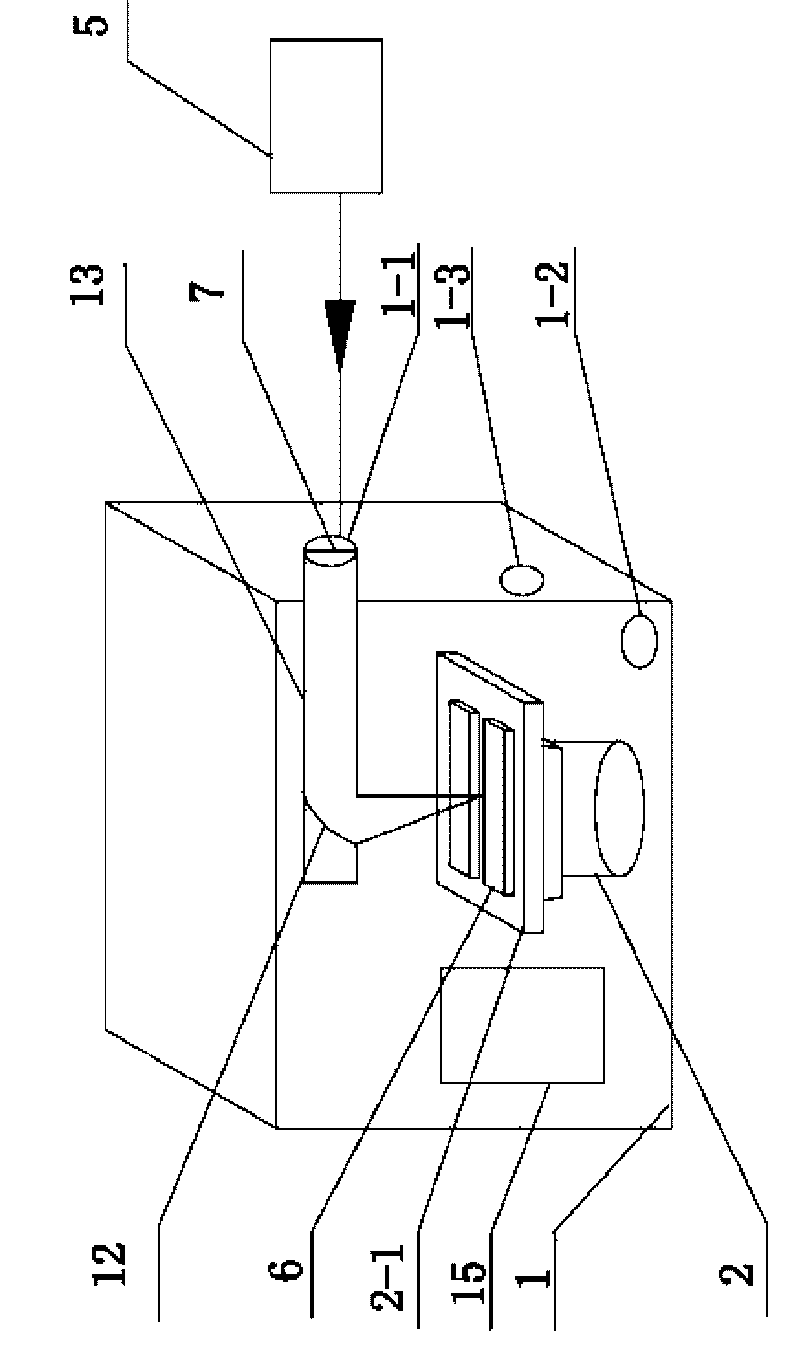

[0012] Specific implementation mode three: combination figure 2 Describe this embodiment, the device of this embodiment comprises workbench 2, laser 5, planar lens 7, reflective focusing lens 12 and reflective focused laser beam welding torch head 13, described reflective focused laser beam welded torch head 13 is Right-angled shape, the reflective focusing lens 12 is installed on the mirror holder at the 90 ° corner in the reflective focused laser beam welding gun head 13, the device also includes a vacuum chamber 1, and the workbench 2 is installed in the vacuum chamber 1 Inside, the side wall of the vacuum chamber 1 is provided with a first through hole 1-1, and the central axis of the first through hole 1-1 is arranged parallel to the upper table surface 2-1 of the workbench 2, and the workpiece 6 is arranged On the upper table 2-1 of the workbench 2, the reflective focused laser beam welding torch head 13 is arranged in the vacuum chamber 1, and the tail of the reflectiv...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap