Drawing wire type serial mechanical arm

A manipulator and wire-pulling technology, which is applied in the field of serial manipulator structures, can solve the problems of large and complex parallel manipulator structures, reduce costs and energy consumption, and is not suitable for miniaturization, so as to overcome the bearing capacity and flexibility of movement and reduce the number of additional devices. , Overcome the effect of small workspace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

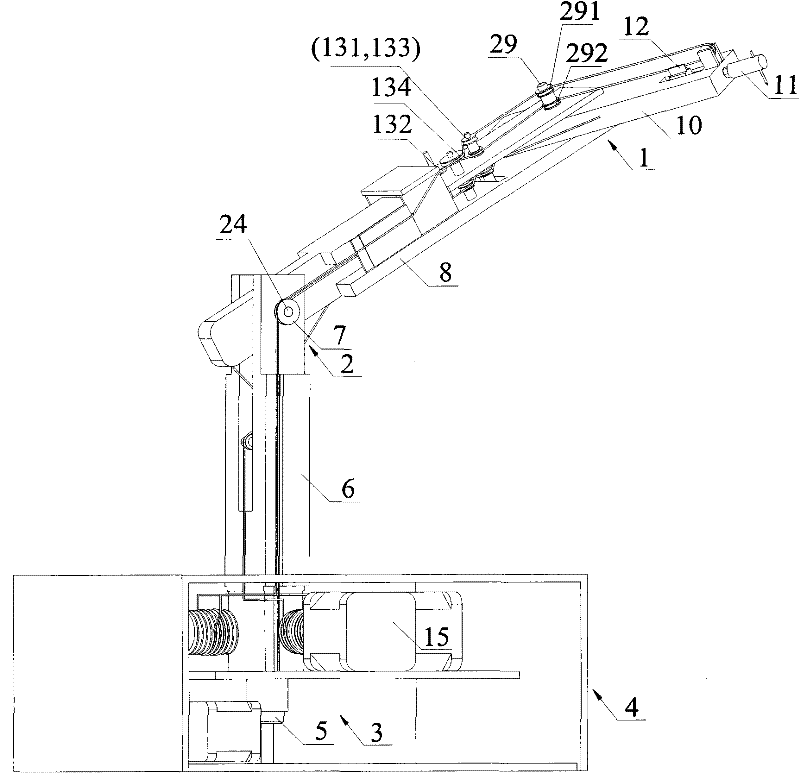

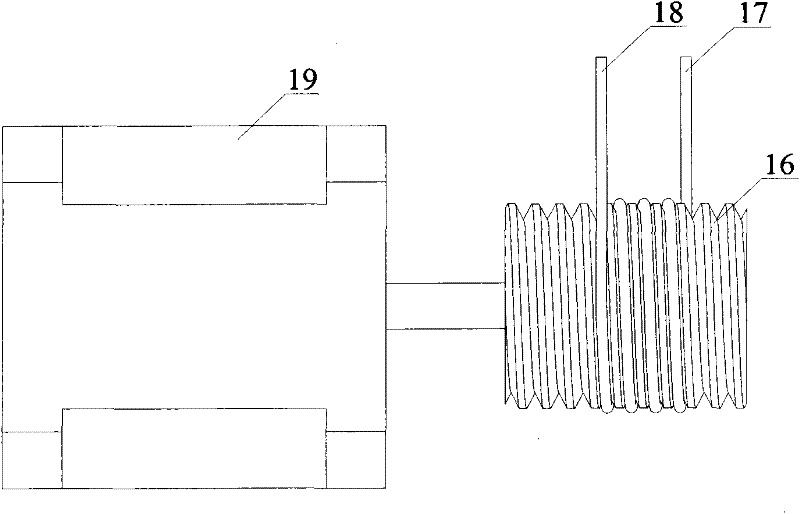

[0024] In this embodiment, the design of the drive box of the manipulator base: the motor winding mechanism is installed in the drive box of the manipulator base, and the winding mechanism is a spiral cylinder with a thread groove, which is directly installed on the rotating shaft of the motor, and is used for pulling and manipulating the pull wire. Movement; the rotation of the helical cylinder winding mechanism can make one end of the control cable wound in the spiral groove stretch, while the other end shortens, and the elongation and shortening of the two control lines are the same, so as to ensure that the control line maintains Tensioned state.

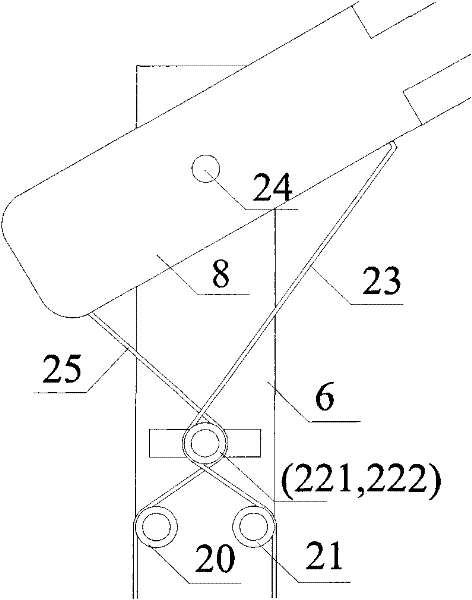

[0025] The design of each joint: including the wrist joint with 2 degrees of freedom, the elbow joint with 1 degree of freedom and the shoulder joint with 2 degrees of freedom.

[0026] The wrist joint includes a wrist joint shaft, a wrist joint rod and a wrist joint axial rotation mechanism. The wrist joint rod is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com