Bridge steel and concrete mixing section constructing method

A steel-concrete combination and construction method technology, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as easy delays in construction period, immature and reliable construction quality, and difficulty in ensuring construction quality, achieving significant economic benefits and simple construction methods , the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

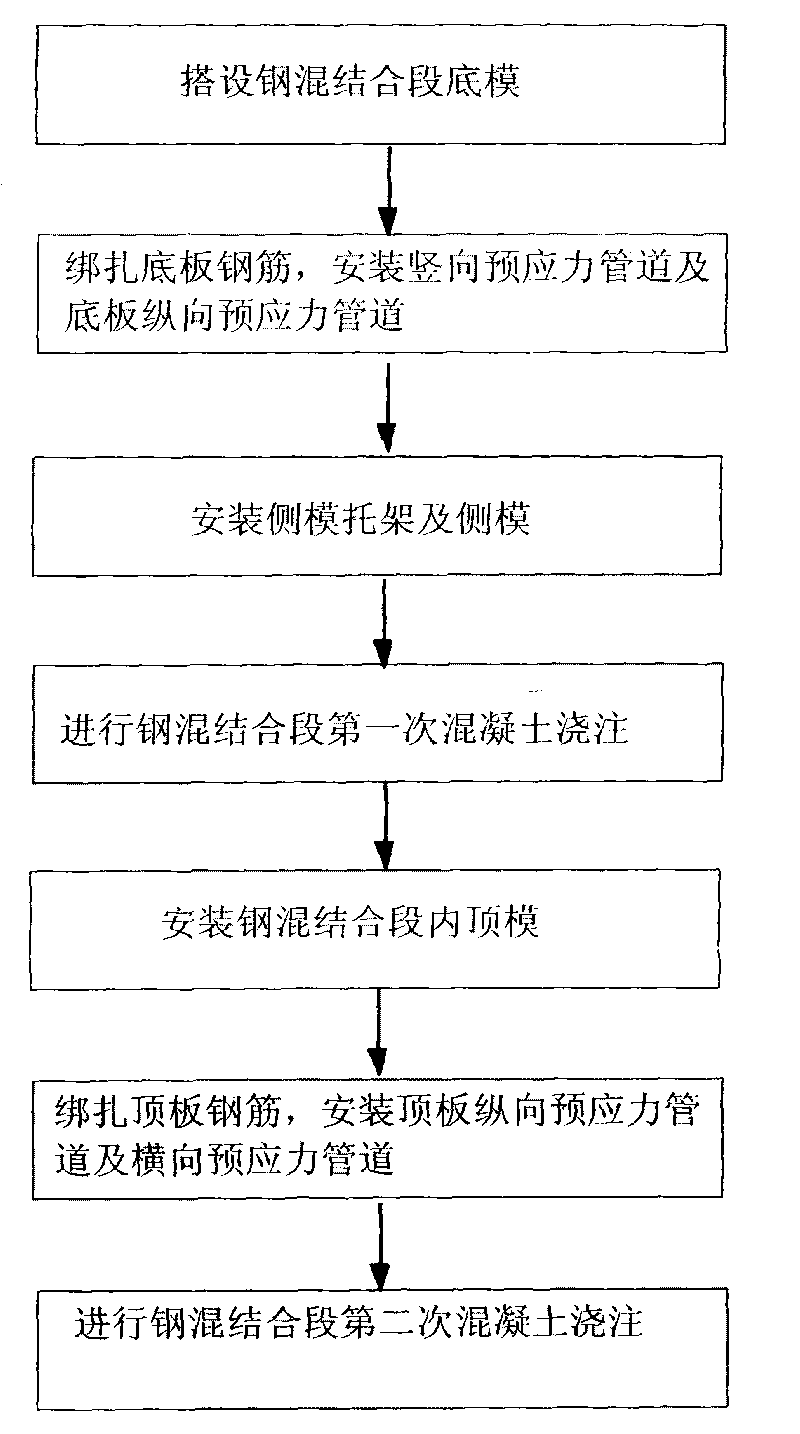

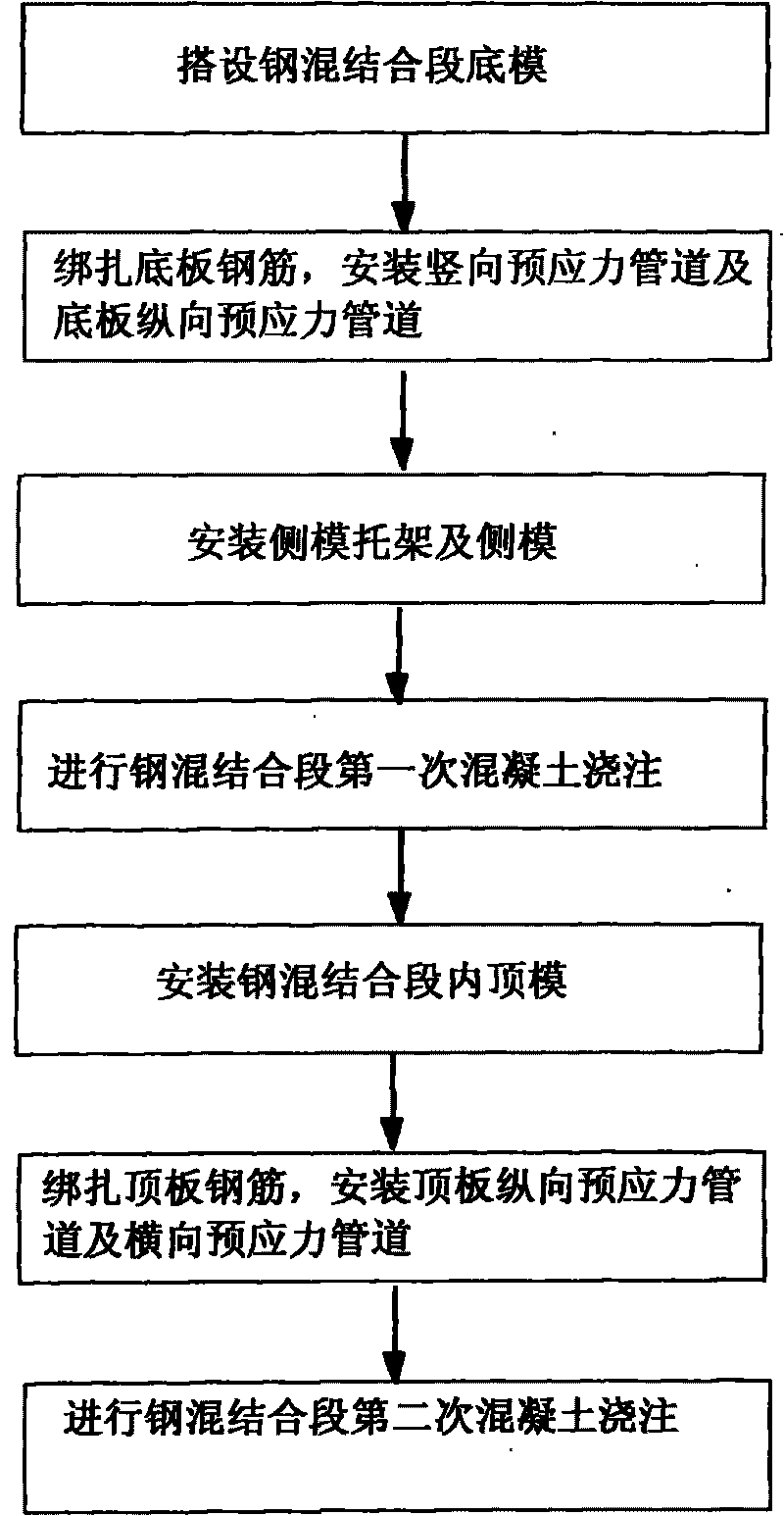

[0026] see figure 1 As shown, the bridge steel-concrete combination section construction method flow process provided by the present invention comprises the following steps:

[0027] Step 1. Set up the bottom mold of the steel-concrete joint section;

[0028] Step 2, binding the steel bars of the floor, installing the vertical prestressed pipe and the longitudinal prestressed pipe of the floor;

[0029] Step 3. Install the side form bracket and side form;

[0030] Step 4, carry out the first concrete pouring of the steel-concrete joint section;

[0031] Step 5. Install the top mold in the steel-concrete joint section;

[0032] Step 6, binding the roof reinforcement, installing the roof longitudinal prestressed pipe and transverse prestressed pipe;

[0033] Step 7: Carry out the second concrete pouring of the steel-concrete joint section.

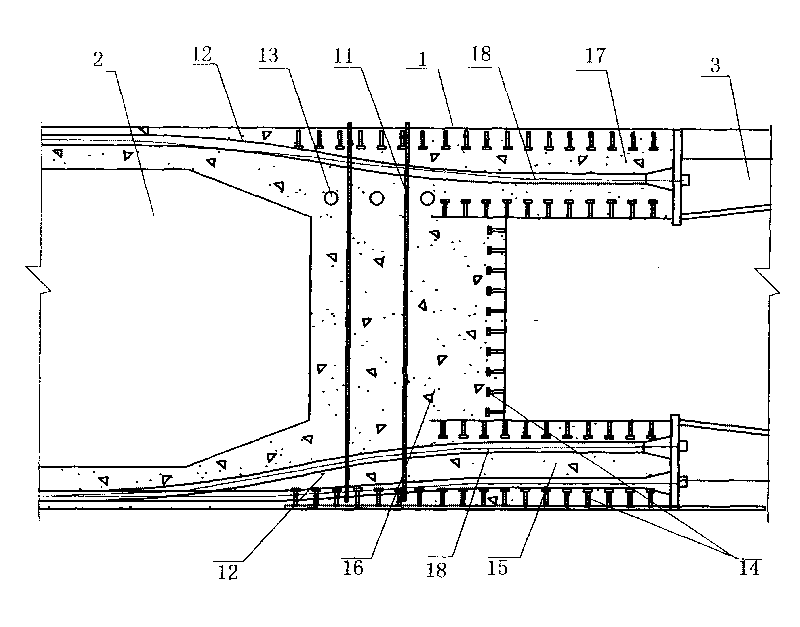

[0034] figure 2 Shown is a vertical structural sectional view of the steel-concrete combination section of the bridge. The steel-con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com