Mountainous area multifunctional bridge conveying-erecting machine and bridge-erecting method

A girder transporter and multi-functional technology, applied in bridge construction, erection/assembly of bridges, bridges, etc., to achieve the effects of simplifying procedures, improving stability, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

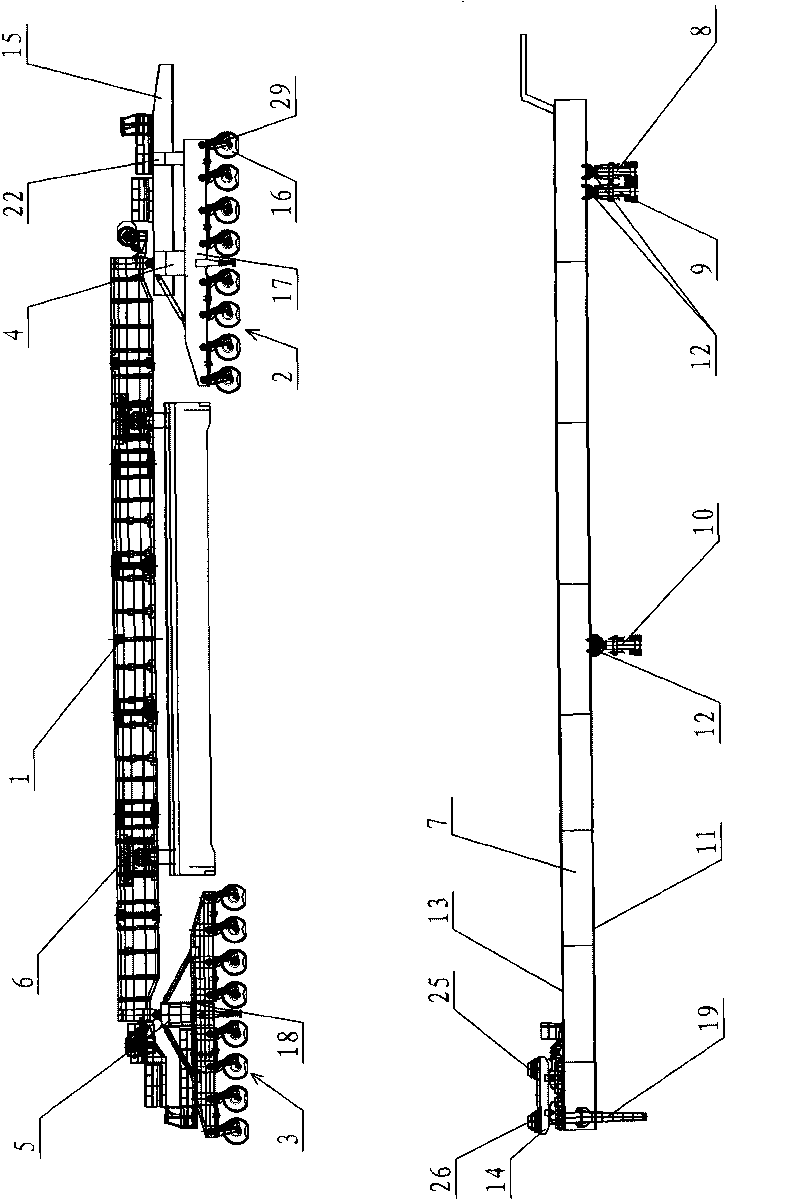

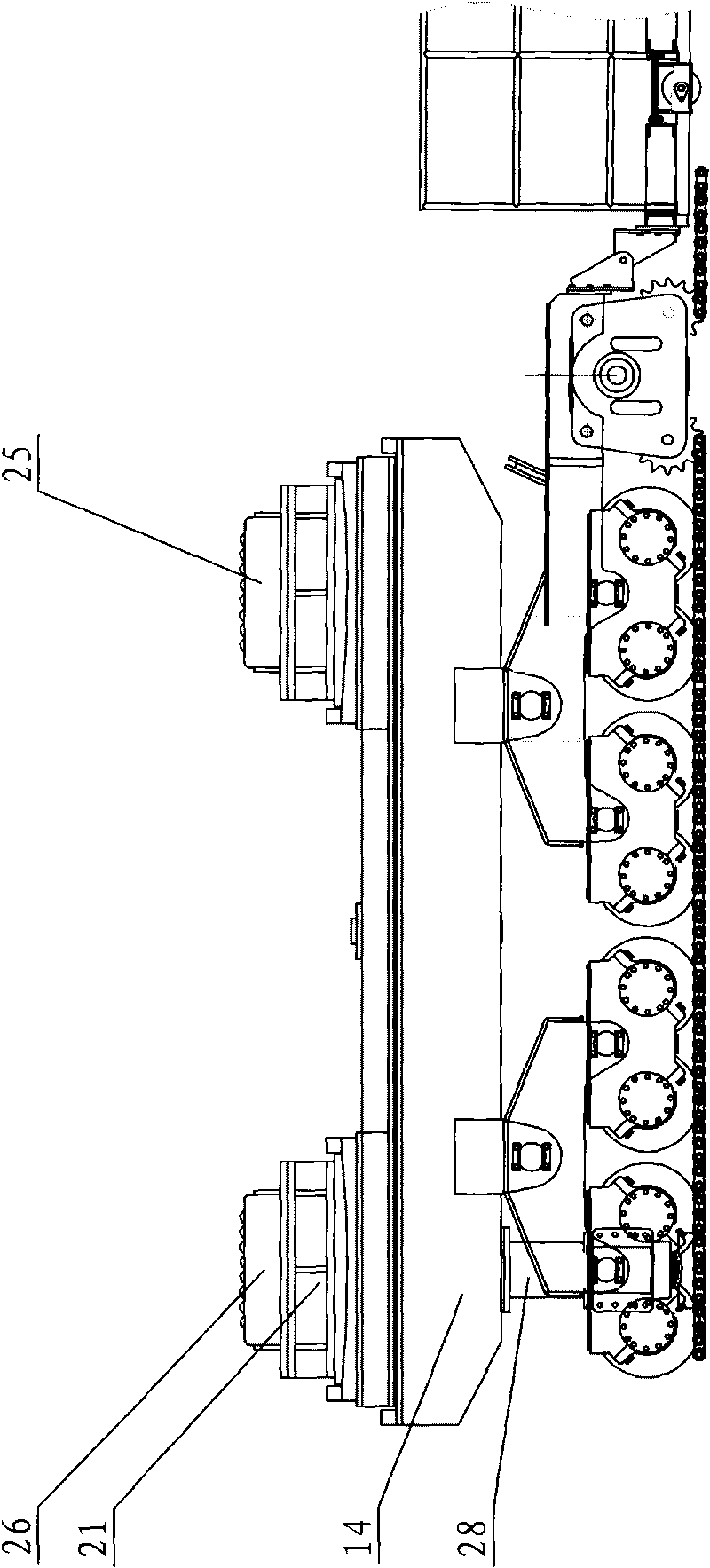

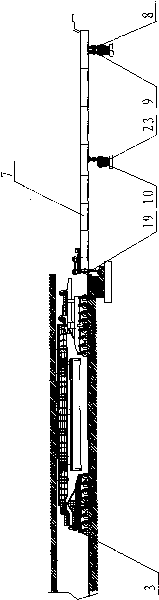

[0037] like figure 1 As shown, the multifunctional beam transporting machine in the mountainous area of the present invention includes a beam transporting machine and a lower guide beam machine, and the beam transporting machine includes a beam transporting machine and a lower guiding beam machine, and the beam transporting machine includes a main girder 1 and front and rear beams. Traveling wheel group 2,3, front and rear traveling wheel group 2,3 comprise some wheels to 16 and front and rear longitudinal vehicle frame 17,18, be provided with lifting oil cylinder 29 between wheel to 16 and front longitudinal vehicle frame 17. Front and rear longitudinal vehicle frames 17, 18 are equipped with front and rear support frames 4, 5 respectively, the front support frame 4 is a saddle type, and the upper ends of the front and rear support frames 4, 5 are respectively connected with the two ends of the main beam 1 by pins. The shafts are hinged, and the bolts on the front support f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com