Heaving plunger cylinder-type wave energy generation system

A power generation system, plunger cylinder technology, applied in ocean energy power generation, engine components, machines/engines, etc., can solve the problems of low secondary energy conversion efficiency, no wave power generation system, and weak adaptability of small wave energy , to achieve the effects of strong wave adaptability, strong wind and wave resistance, and enhanced wind and wave resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

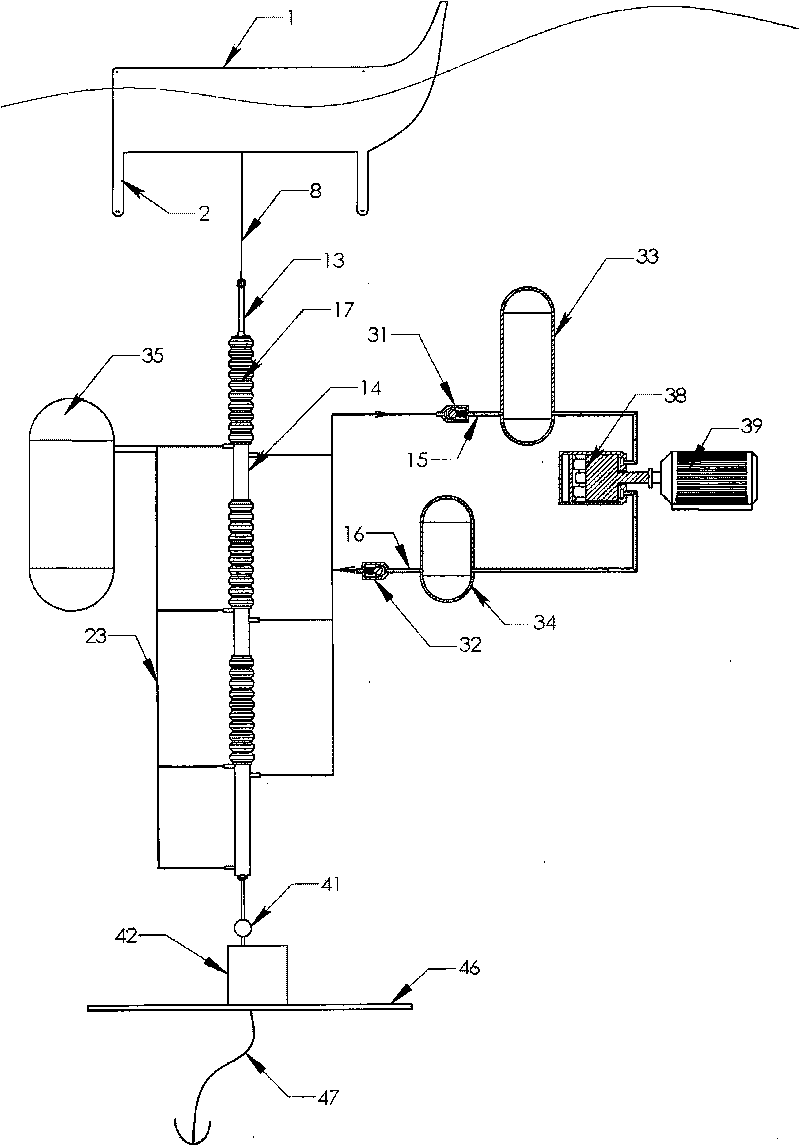

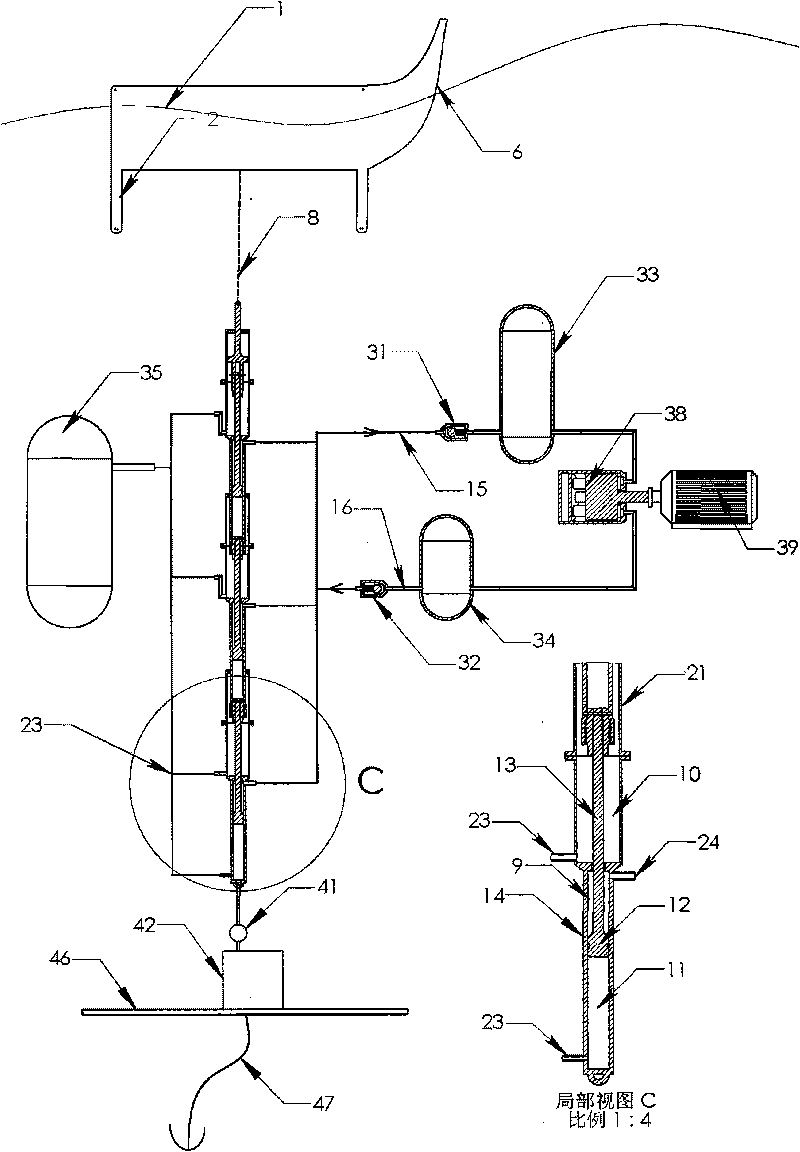

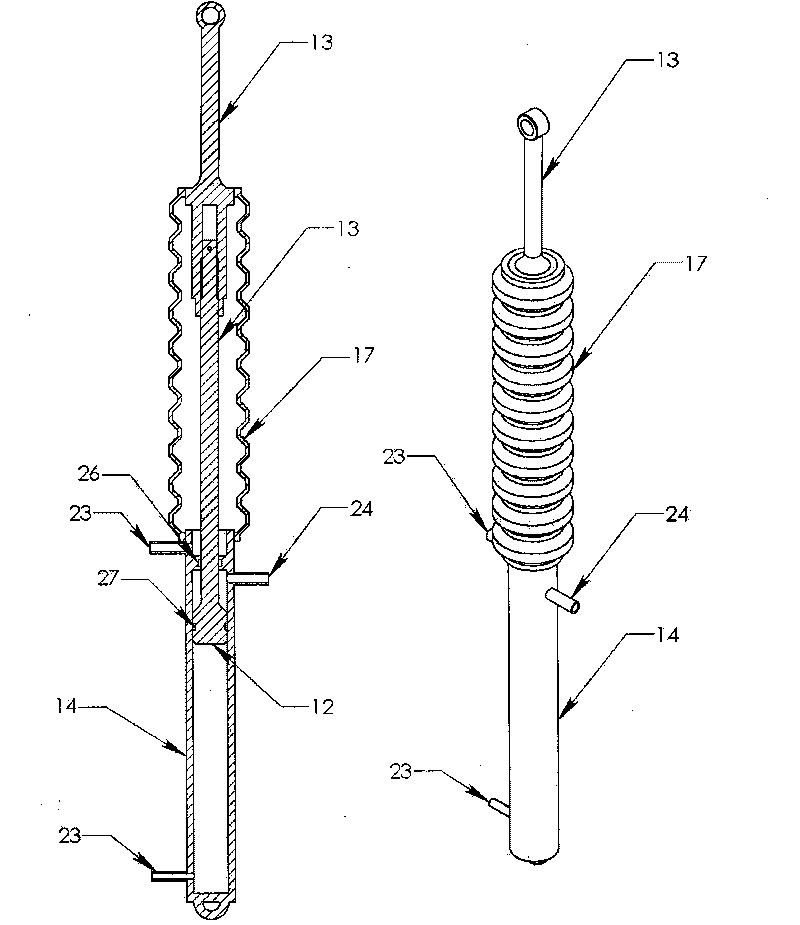

[0076] The wave energy power generation system is a heave type, including a floating body, a rope, a hydraulic transmission system, a generator, and a base. The input end of the hydraulic transmission system is a plunger cylinder, and the piston rod (13) of the plunger cylinder passes through the rope ( 8), connect the floating body (1), and the plunger cylinder body (14) is connected to the base; the inlet and outlet oil ports (24) of the oil chamber (9) of the plunger cylinder are divided into two paths, and one path passes through the oil outlet check valve ( 31), the high-pressure pipeline (15) is connected to the high-pressure accumulator (33), and the other way is connected to the medium-pressure accumulator (34) through the oil return check valve (32) and the oil return pipeline (16); the plunger The rodless chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com