Method for controlling and optimizing performance heater

An optimization method, heater technology, applied in the combustion method, fuel heating of turbine/propulsion, liquid fuel supply/distribution, etc. The effect of reducing fuel consumption, improving economic efficiency and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0042] In the following logic, "1" means that the status signal or command is valid, and "0" means that the status signal or command is invalid.

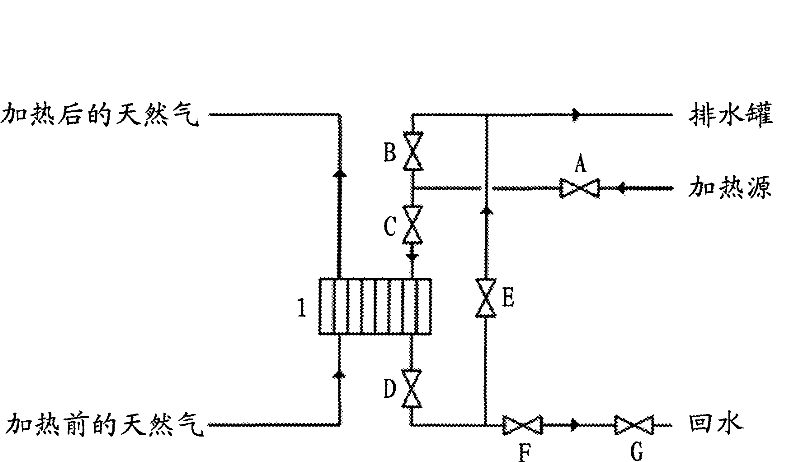

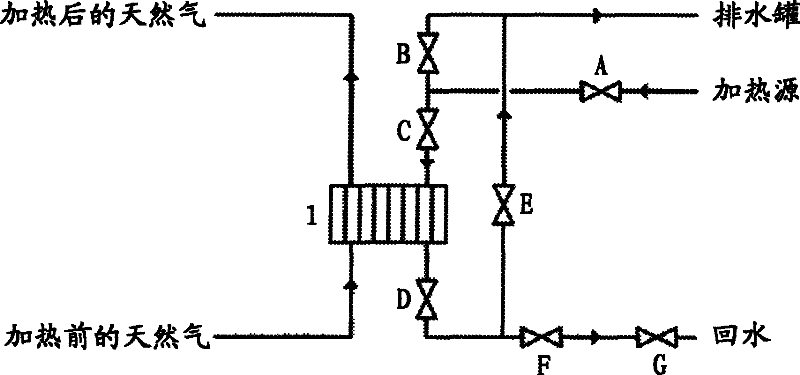

[0043] In order to prevent the valves of the gas turbine performance heater from exiting the working state due to the feedback fault of the stroke switch (in the working state, the primary water inlet valve A, the secondary water inlet valve C, the primary water outlet valve D, and the secondary water outlet valve F are open. Inlet-side discharge valve B, outlet-side discharge valve E are closed), thereby essentially tripping the performance heater. This leads to the following logical steps:

[0044] When the open feedback or close feedback signal of a certain valve is "0" at the same time, the protection of the valve is cancelled, and no command is issued to make the valve exit the operating state;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com