Solar hot water heating system

A technology for solar hot water and heating systems, applied in hot water central heating systems, solar thermal power generation, heating systems, etc., can solve problems such as inability to replenish water in water tanks, complicated installation, shortened lifespan, etc., and achieve easy maintenance and management. Comfortable to wash and stable in mixed water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

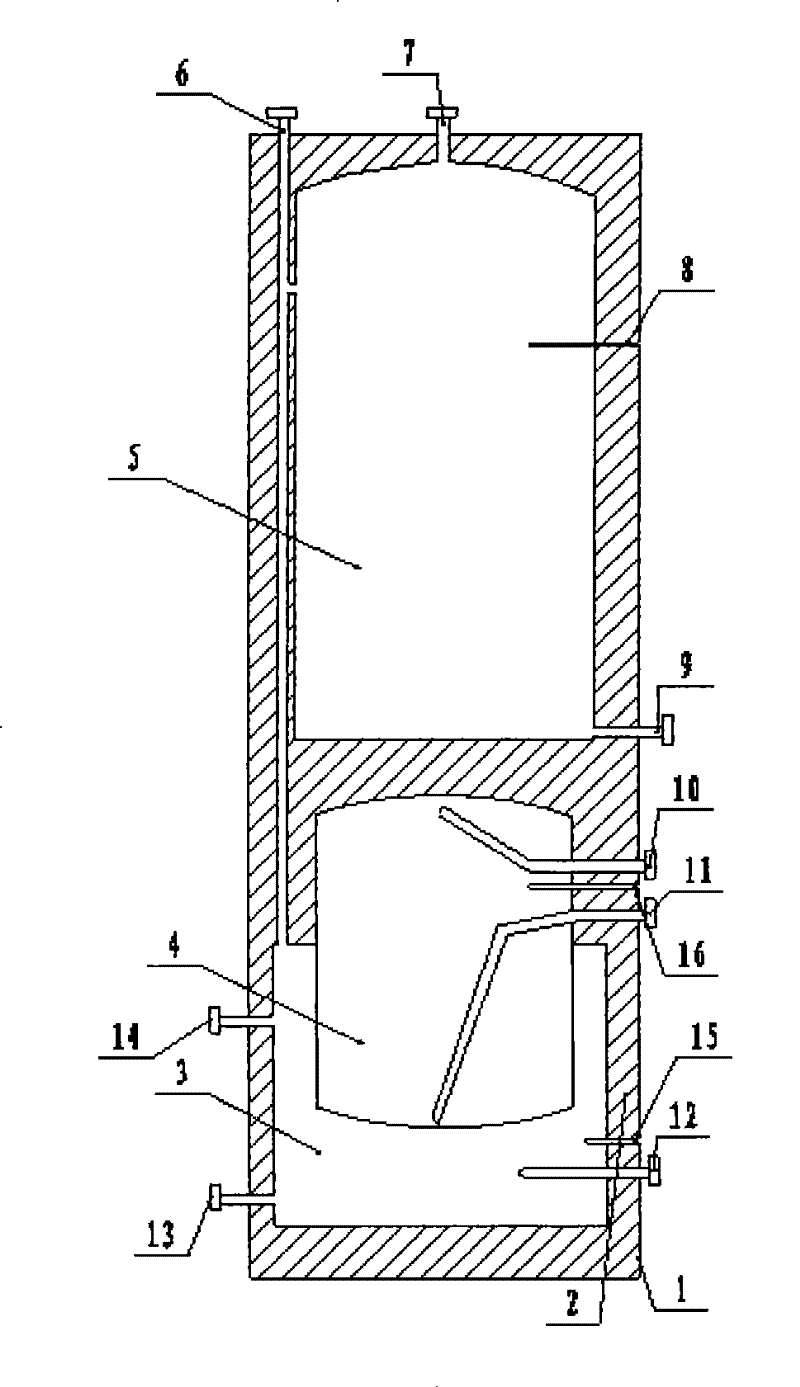

[0039] figure 1 Represent a three-bladder water tank, which is one of the most critical parts of the present invention. The water tank includes an outer shell 1, a thermal insulation foam layer 2, a non-pressure-bearing lower inner tank 3, a non-pressure-bearing upper inner tank 5, a pressure-bearing inner tank 4, an exhaust pipe 6, and an exhaust pipe 7 (also a liquid level sensor placement port) ), temperature control blind pipes 8, 16, 15 and a plurality of water inlets and outlets constitute. Among them, the water inlet and outlet include auxiliary heating return water inlet 9, hot water supply inlet 10, cold water inlet 11, electric heating pipe interface 12, circulating water pump water inlet 13, solar heat collector return water inlet 14, etc.

[0040] The three inner tanks in the three-tank thermal water tank form a multi-inner tank thermal water tank, wherein two non-pressurized inner tanks 3 and 5 form a heating medium storage area, and the pressure-bearing inner ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com