Display panel, alignment method and operation method thereof, and color filter substrate

A color filter substrate and display panel technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as uneven display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

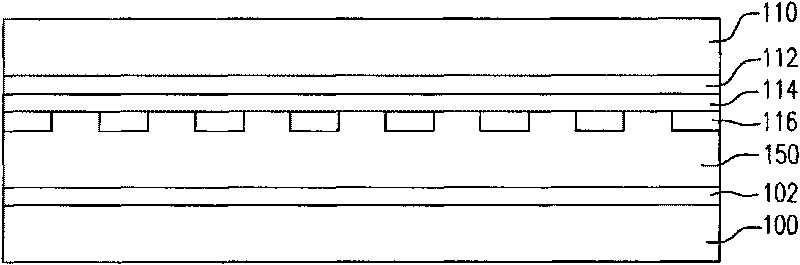

[0041] figure 1 is a schematic cross-sectional view of a display panel according to an embodiment of the present invention. Please refer to figure 1 , the display panel of this embodiment includes a first substrate 100 , a second substrate 110 and a liquid crystal layer 150 located between the first substrate 100 and the second substrate 110 .

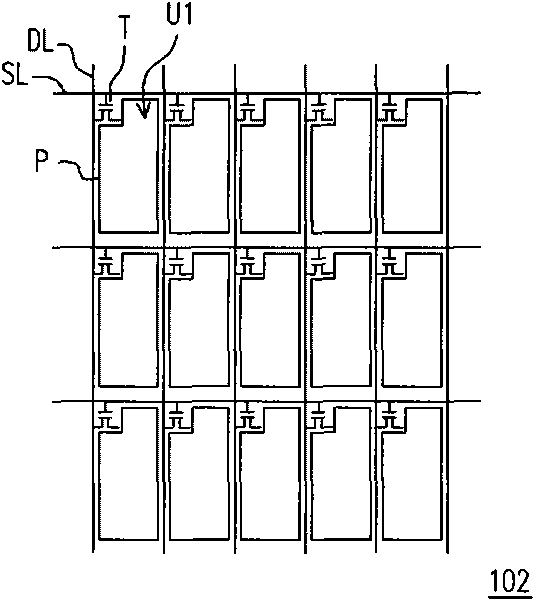

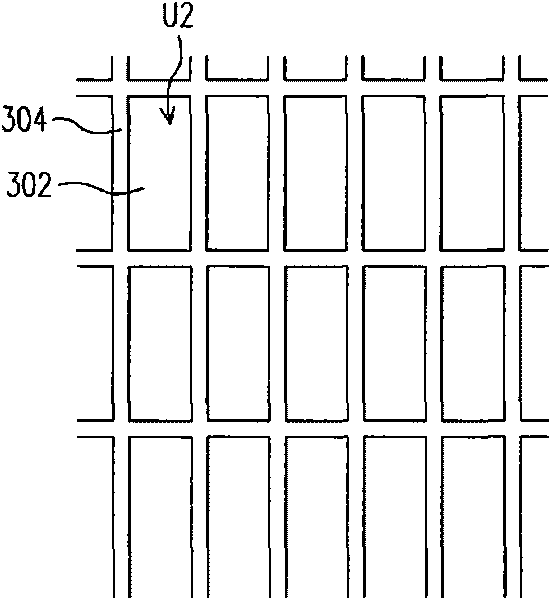

[0042] The material of the first substrate 100 can be glass, quartz, organic polymer or metal and so on. A pixel array layer 102 is provided on the first substrate 100, and the pixel array layer 102 is as Figure 2A As shown, it is composed of multiple pixel structures U1, and the layout of each pixel structure U1 is as follows image 3 shown. For more details, please also refer to figure 1 , Figure 2A and image 3 Each pixel structure U1 of the pixel array layer 102 includes a scan line SL and a data line DL, an active element T, a storage capacitor electrode line 202 , an upper electrode pattern 204 and a pixel electrode P. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com