Lateral side cooling structure for drift section of sheet beam klystron

A cooling structure and strip-shaped technology, applied in the microwave field, can solve problems such as welding difficulties, easy deformation of electronic injection channels, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to help a better understanding of the present invention, specific embodiments of the present invention will be described below with reference to the accompanying drawings.

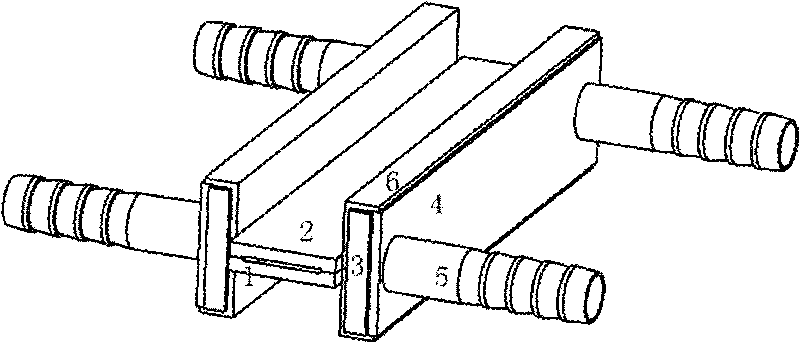

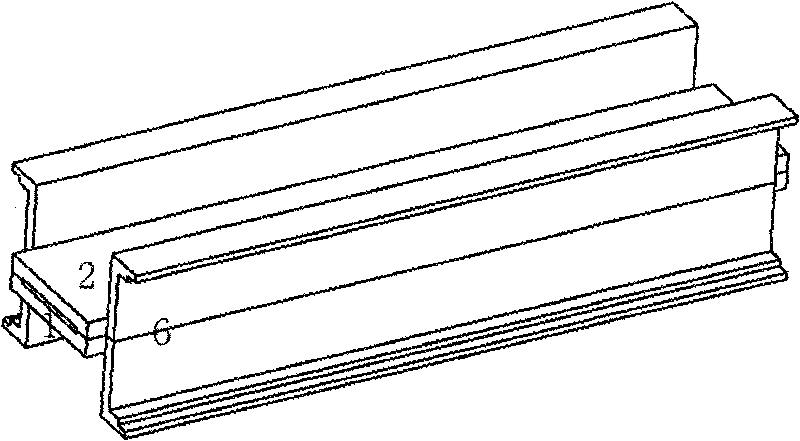

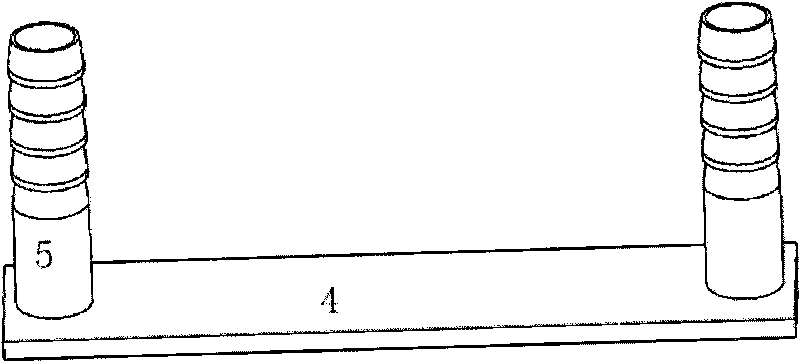

[0023] The side cooling structure of the drift section of a strip-shaped injection klystron of the present invention is as follows: figure 1 As shown, it consists of the following parts: the main body of the drift section, the waterway end cover 3, the side cooling water cover plate 4 and the water nozzle 5.

[0024] The drift section includes the upper wall 1 of the drift section and the lower wall 2 of the drift section. The upper and lower walls 1 and 2 of the drift section are axially provided with through rectangular long grooves, and the square long grooves on the upper and lower walls 1 and 2 are fixed parallel to the axial direction. , so that the two square slots form a through hole mutually. A ∏-shaped side plate 6 is respectively arranged on the left and right sides of the drift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com