Integrated method of coating, intermediate coating, color-registering for cab

A cab, color register technology, applied in the device, coating, surface pretreatment, etc. for applying liquid to the surface, can solve the problems of high energy consumption, affecting production efficiency, energy consumption burden, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

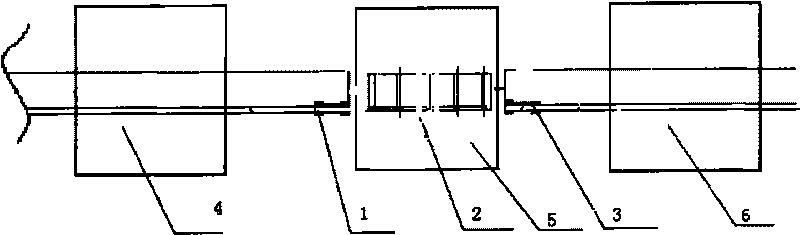

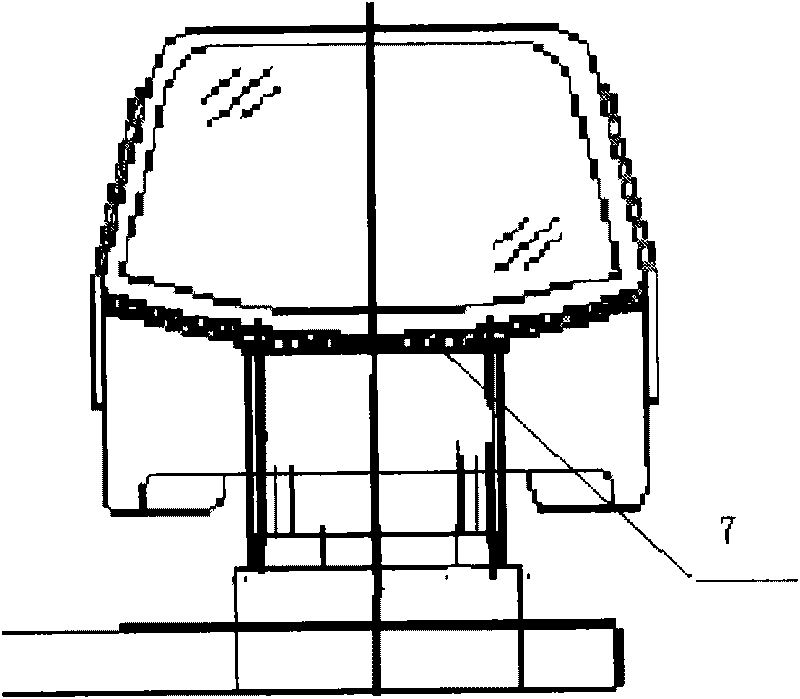

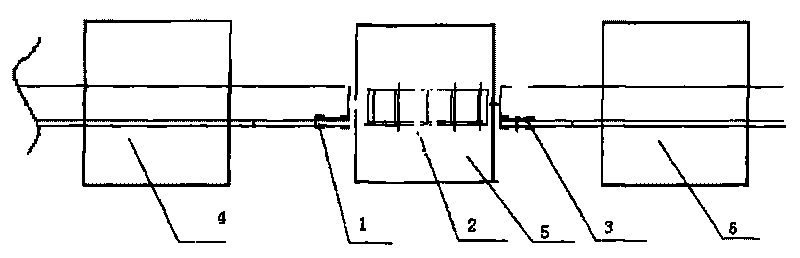

[0020] Example 1. The technological process of the present invention is primer spraying-middle coat spraying-chromatic spraying-drying-upper masking material-overall cab spraying-drying. like figure 1 As shown, after the cab is sprayed with the primer in the primer spraying room 4, it is transported by the primer conveyor chain 1 to the intermediate coating and color registration room 5, and the intermediate coating and color registration are sprayed on the moving roller 2 of the intermediate coating room. The color registration part 7 is as follows: figure 2 The shaded part shown in the case is then transported to the drying chamber 6 through the accumulation chain 3 for integrated drying.

[0021] The specific steps are:

[0022] Use glue coating equipment to spray the cab weld glue and PVC underbody paint. The underbody paint grade CM-PVC-III is produced by Changchun Henkel Surface Technology Co., Ltd.

[0023] Transfer the sprayed welding seam adhesive and vehicle bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com