One-time molding process of multiple fan-shaped plates

A forming process, a technology of fan-shaped plates, applied in the field of one-time forming process of multi-piece fan-shaped plates, can solve the problems of high production cost, large material waste, and material utilization rate of only 78%, so as to save raw materials and production costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The one-time molding process of multiple fan-shaped plates is completed according to the following steps:

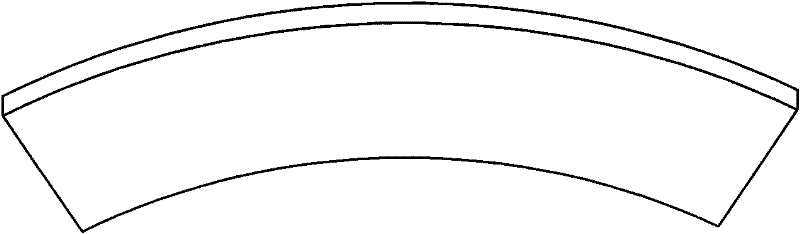

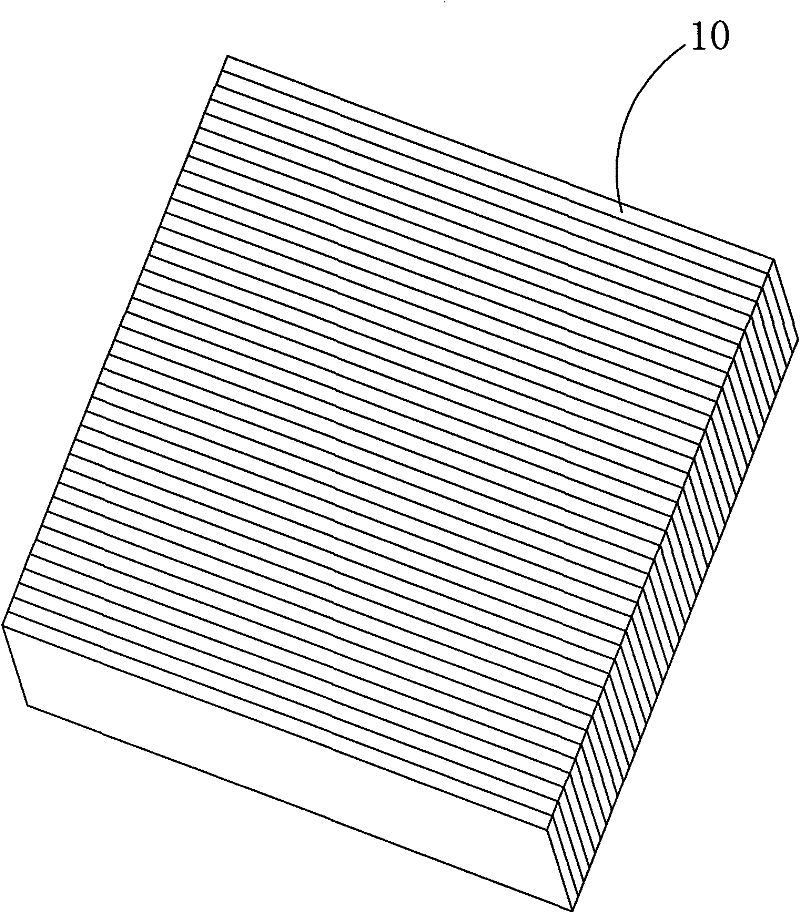

[0025] (1) Make blank 10 according to the size corresponding to the fan-shaped plate with a length of 412 mm and a width of 25 mm and a thickness of 1.2 mm.

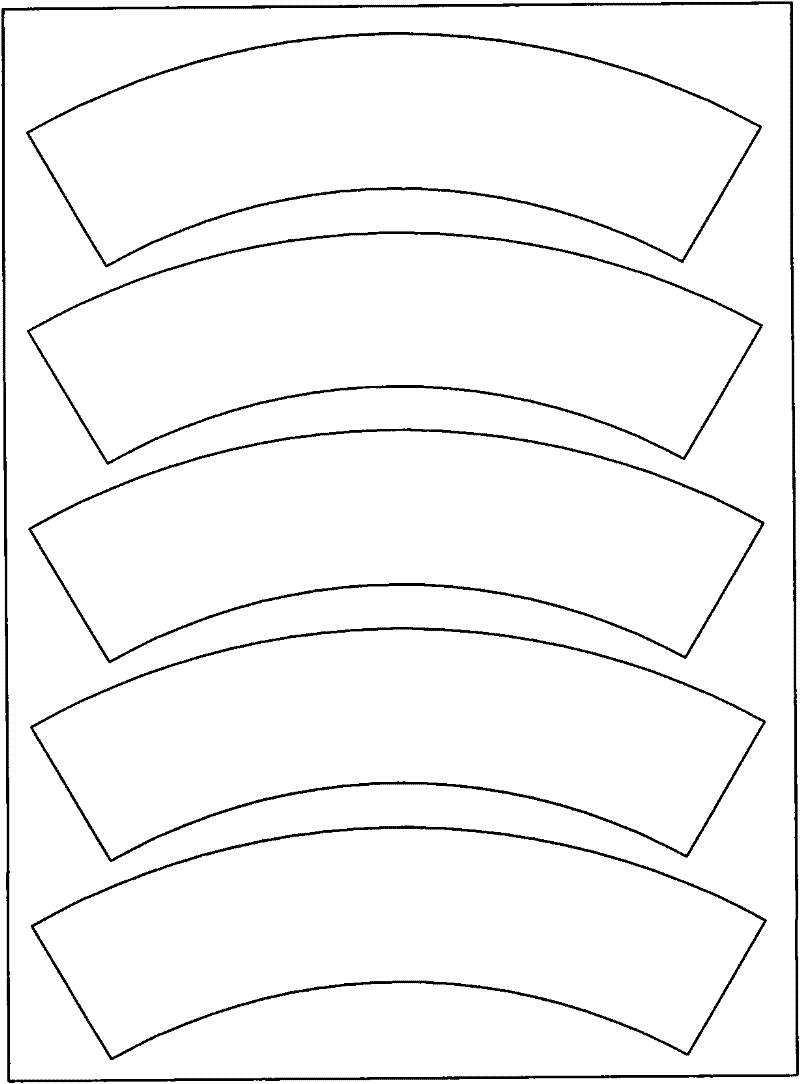

[0026] (2) 40 stamping blanks 10 produced in step (1) are aligned and superimposed on each other according to corresponding sides;

[0027] (3) Put the stacked stamping blank 10 into the lower fan-shaped die 30 of the stamping mold from one side of the stamping mold in the direction in which the plate surface of the single stamping blank 10 is upright, and use the stopper 32 and the movable splint 33 Position and clamp the stacked stamping blanks 10 horizontally and vertically;

[0028] (4) Start the punching machine, the upper fan-shaped punch 31 and the lower fan-shaped die 30 of the punching machine are matched with the concentric circles, and the stamping blank 10 is punched into a fan-shaped plate;

...

Embodiment 2

[0033] The one-time molding process of multi-piece fan-shaped boards is basically the same as the one-time molding process of multi-piece fan-shaped boards in Example 1. The difference is that the mold is opened and the mold is held for 1 to 5 seconds after closing the mold, and the mold is taken out. Stamped fan-shaped panels.

[0034] The specifications of the products manufactured by the above-mentioned production process are: the central angle of the fan-shaped plate reinforcement is 60 degrees, the radius of the inner circle is R=400mm, the width of the plate is b=25mm, and the material is aluminum alloy LY12-t1.2;

[0035] The fan-shaped plate produced: no wrinkle, no cracking, the radius rebound is 1-2mm, the outer edge of the fan-shaped plate is thinned by 0.01-0.1mm, and the inner edge is thickened by 0.01-0.12mm, which meets the IT14 precision standard .

[0036] Utilizing the principle of the invention, the upper and lower fan-shaped concave-convex dies are set to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

| Inner radius | aaaaa | aaaaa |

| Board width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com