Automatic feeding device for die punching

An automatic feeding and punching technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of unsafe manual operation, low processing precision, slow processing speed, etc., achieve labor intensity reduction, reasonable structural design, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

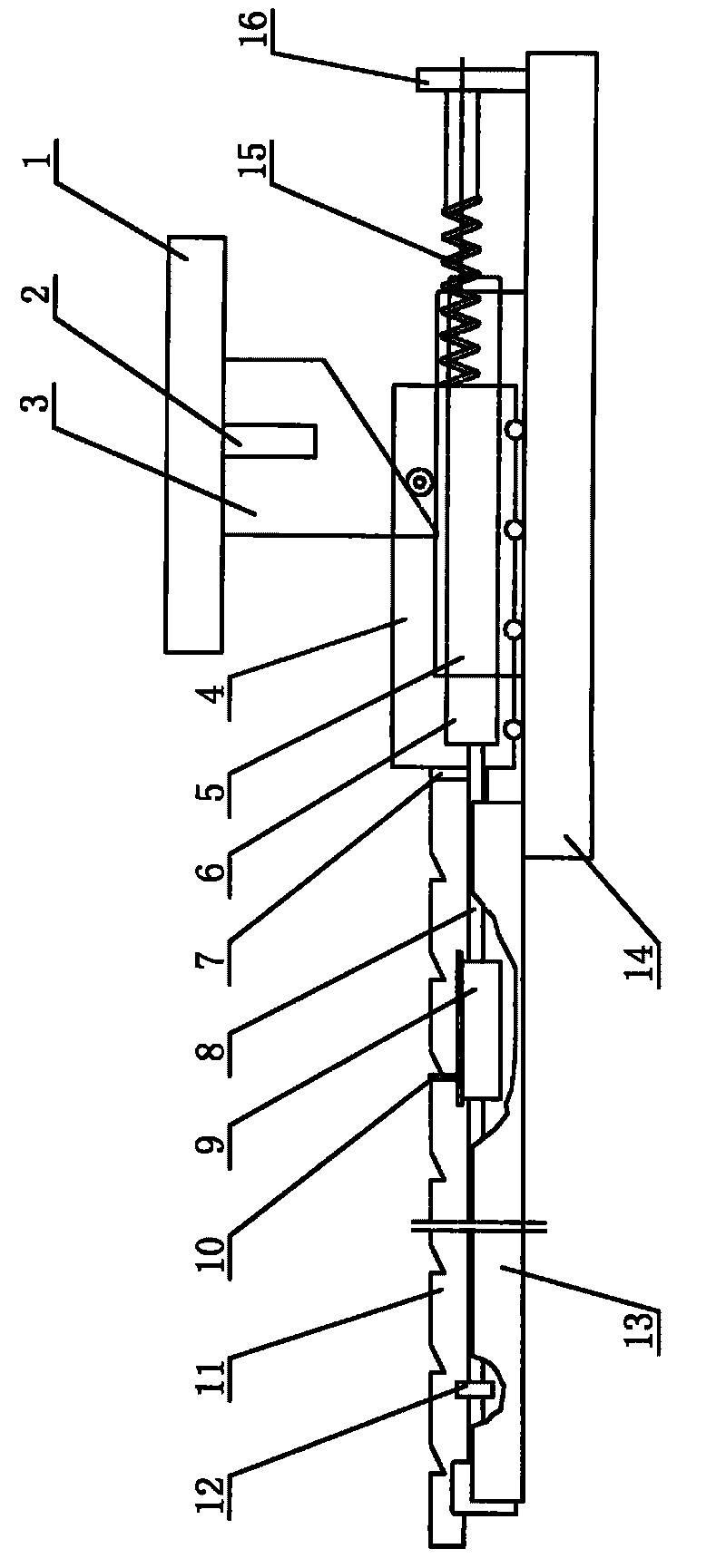

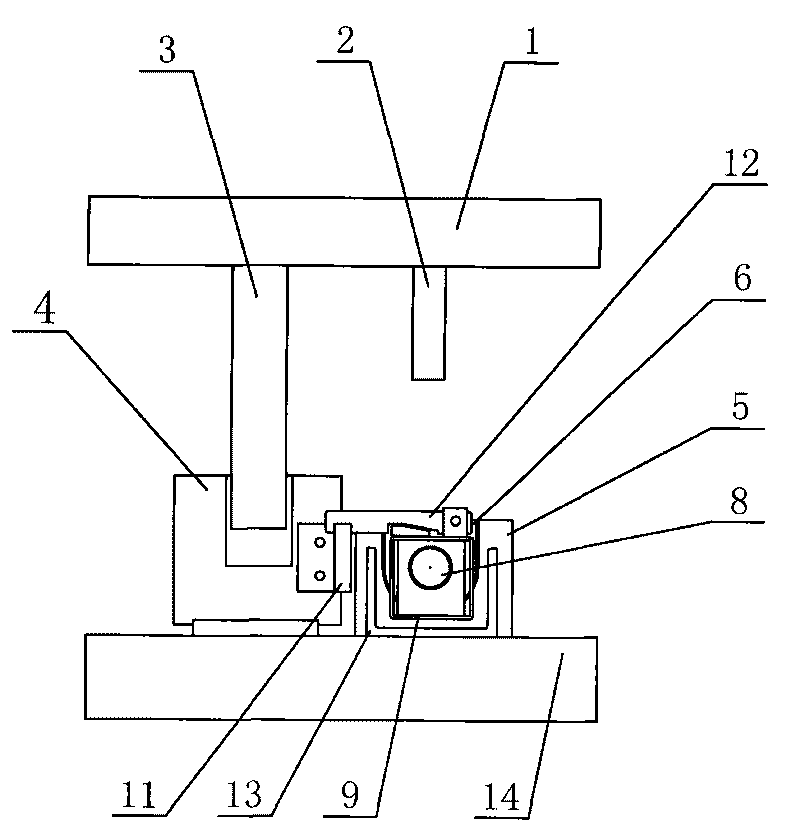

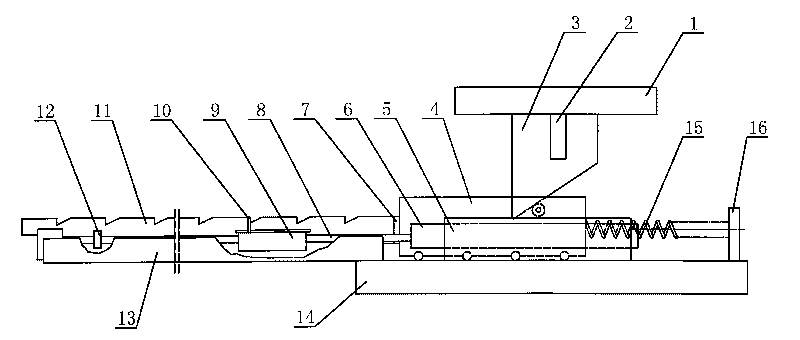

[0009] An automatic feeding device for die punching, such as figure 1 , figure 2 As shown, it includes an upper mold base 1 and a lower mold base 14, the upper and lower molds are fixed on the punching machine, and the upper mold base 1 is fixed with punching and shearing blades 2 and inclined irons 3; the middle part of the lower mold base 14 is fixed with a lower die 5, and the front An extension plate 13 is fixed, and a fixed plate 16 is installed at the rear; the fixed plate 16 is provided with a spring 15, and the front end of the spring 15 is connected with a slider 4, and the front end of the slider 4 is provided with a baffle plate 7 and a rack plate 11; The front end is fixed on the extension plate 13, the mandrel 6 is fixedly installed on the rear end, and the front end of the support rod 8 is fixed with a scale plate 12; Rod 10 head is stuck in the tooth groove of rack plate 11.

[0010] When the steel pipe is punched, the device of the present invention is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com