Replacement construction technology of secondary superheater for dry quenching boiler

A construction technique and superheater technology, applied in coke ovens, petroleum industry, coke cooling, etc., can solve problems such as high requirements for lifting operations, large number of welding joints in pressure pipes, and heavy welding workload, so as to improve maintenance efficiency , Significant economic and social benefits, and the effect of saving machinery use and construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

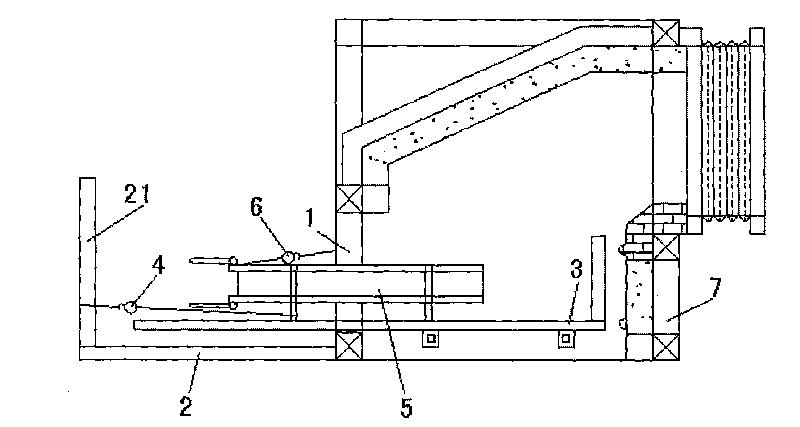

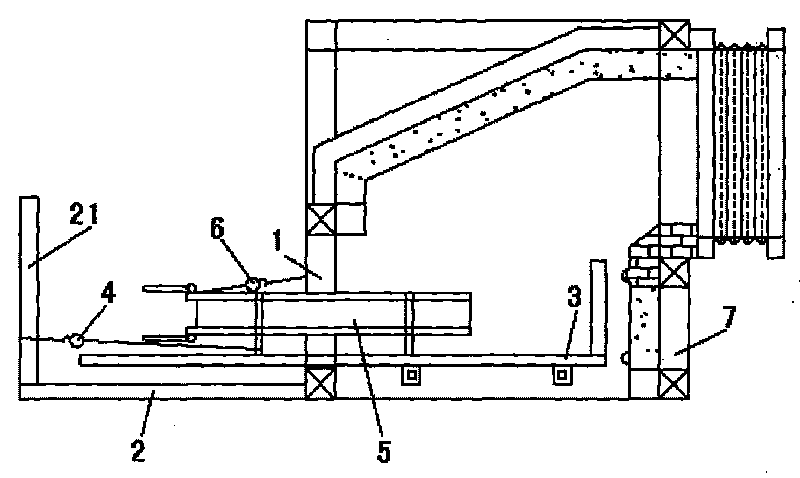

[0021] Below in conjunction with accompanying drawing and specific embodiment further illustrate the utility model.

[0022] Such as figure 1 , figure 2 As shown, the CDQ boiler secondary superheater replacement construction process of the present invention comprises the following steps:

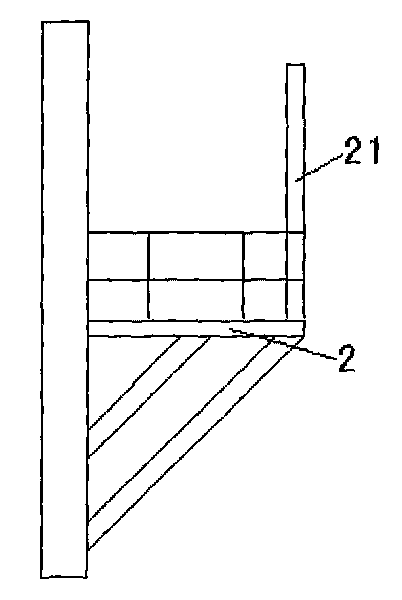

[0023] (1) Remove the original platform at the front wall panel 1, and build an inspection platform 2 at the front of the furnace body; since the old platform at the front wall panel cannot bear the weight of the superheater and the wall panel, the original platform of the front wall panel must be removed The maintenance platform is set at the elevation of 19.3m on the front side of the furnace body. The maintenance platform 2 is welded with 16# channel steel and 250×250×14 H-shaped steel to form a frame structure. The maintenance platform is 5m wide and 6.5m long.

[0024] (2) Removal of the front wall panel 1: the front wall panel is mounted on the frame beam of the furnace body. Hang ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com