Protection process of underground drilling hole

A technology of a process and a protection device, which is applied in the field of small-scale engineering construction deep underground, can solve problems such as incomplete drilling, scrapped drilling, and silting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

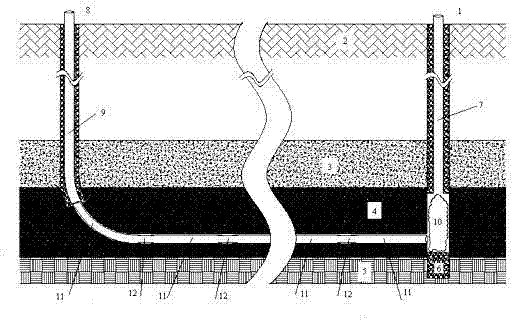

[0037]In this embodiment, directional drilling and vertical drilling will be constructed, and the drilling protection process for both will be implemented. Here, the combination figure 1 Give specific implementation steps.

[0038] First, build a vertical borehole 1 from the ground to the coal seam floor 5 through the surface soil layer 2, rock formation, coal seam roof 3 and coal seam 4, and estimate the position of the lower end of the borehole casing according to the previous drilling data and the calculation formula provided by the present invention. h 2 and borehole protector lower end position H 1 , in the Gonggou coalfield of Xinao Wellless Underground Coal Gasification Ulanqab Test Base, the depths to the ground are 277 meters and 289 meters respectively. When drilling to the lower end position H of the expected drilling casing 2 At the same time, the drilling casing 7 is lowered into the borehole 1, and the drilling casing and the formation are consolidated togethe...

Embodiment 2

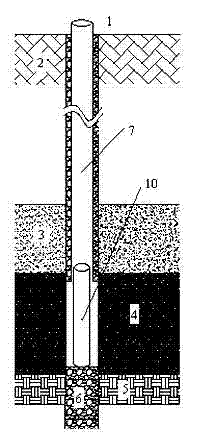

[0044] combine figure 2 The implementation steps of the vertical drilling protection process are described.

[0045] First, use a drilling rig to drill a hole 1 from the ground to the coal seam floor 5 through the surface soil layer 2, the rock layer, the coal seam roof 3, and the coal seam 4. Referring to the previous drilling work in the Ulanchabu Gonggou coalfield, the coal seam is roughly buried. The depth, thickness and other conditions have been mastered, and the position H of the lower end of the drilling casing can be estimated 2 It is 277 meters deep and the lower end position of the drilling protection device is H 1 It is 289 meters deep, after drilling to the lower end position H of the expected drilling casing 2 When the well is washed, the drilling casing 7 is lowered to the bottom of the hole (the lower end of the drilling casing 7) in the borehole 1, and the cement slurry is injected into the well to cement the drilling casing 7 and the formation together. A...

Embodiment 3

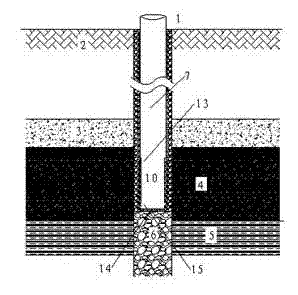

[0051] combine here image 3 The implementation method of the socketed drilling protection process is specifically stated.

[0052] First, build a vertical borehole 1 from the ground to the underground coal seam, pass through the surface soil layer 2, the rock layer, the coal seam roof 3, and the coal seam 4, and drill into or even penetrate the coal seam floor 5. According to the drilling data and coal seam Coring situation, estimate the position H of the lower end of the drilling casing 2 It is 277 meters deep and the lower end position of the drilling protection device is H 1 It is 289 meters deep, and then estimate the amount of grouting cement required for hole bottom reinforcement based on the diameter and depth of the drilled hole.

[0053] Secondly, wash the borehole. After cleaning the mud used for drilling, inject the estimated amount of mud to reinforce the bottom of the hole and wait for solidification to form the bottom reinforcement of the borehole 6 .

[0054...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com