Arbitrary turnover four-stroke engine

A four-stroke engine and generating device technology, which is applied to the lubrication of engine components, machines/engines, and engines, can solve problems such as poor lubrication effects, achieve improved lubrication effects, reduce negative pressure in cylinders, and eliminate oil injection phenomena Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

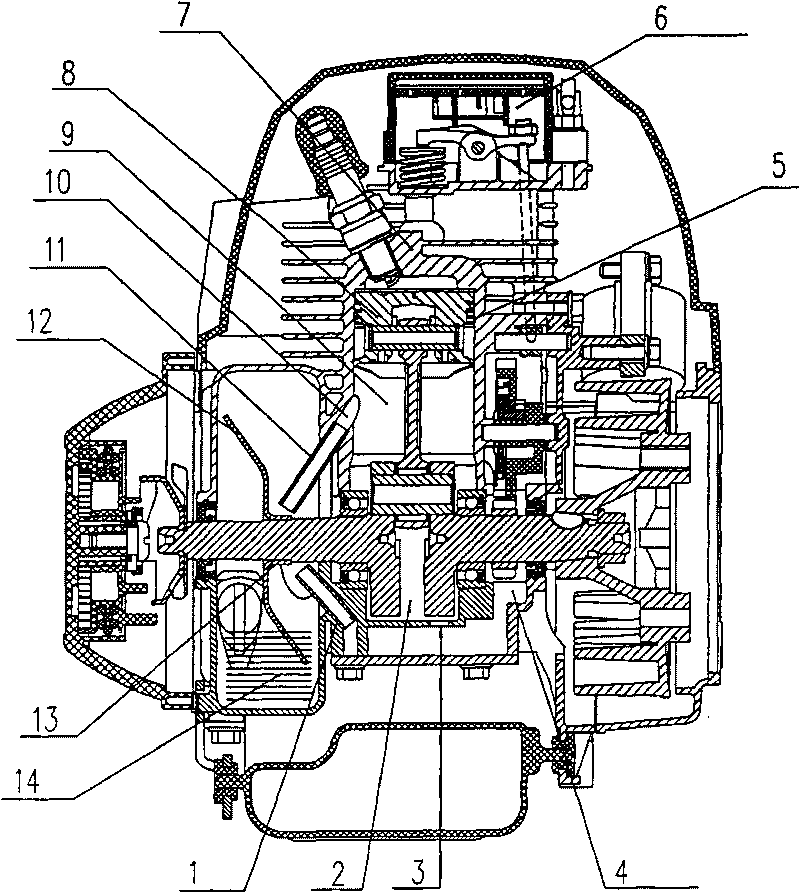

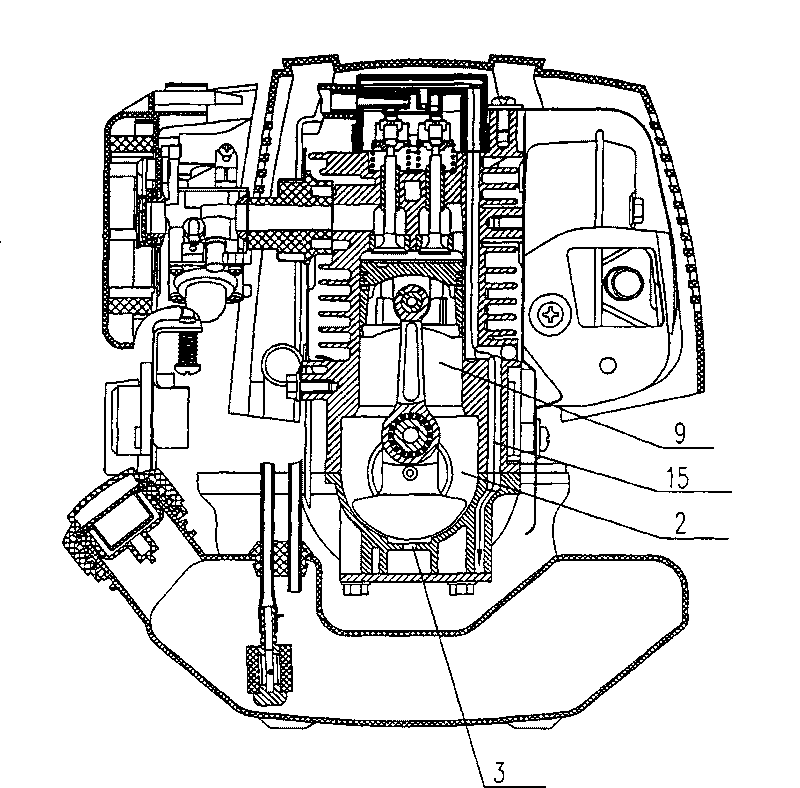

[0018] Such as figure 1 , 2 shown.

[0019] A kind of four-stroke small gasoline engine, comprises body 7, and body 7 can be made up of upper and lower two parts, is provided with oil storage chamber 14, cylinder 9, crankcase 2 in body 7, and cylinder 9 is positioned at the upper half of body 7, and crankcase 2 and Cylinder 9 communicates with and is located at the lower part of body 7. Oil storage chamber 14 is located at one side of cylinder 9 and crankcase 2. The lower part of crankcase 2 is provided with oil outlet 3, and the lubricating oil mist discharged from oil outlet 3 passes through the oil outlet. Channel 4 (see figure 1 ) enters the valve control chamber 6, and is separated from the oil return passage 15 (see figure 2 ) into the oil return channel 1 communicating with the oil storage chamber 14 to complete a cycle and be reused. An oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com