Arbitrary overturn four-stroke cycle engine

A four-stroke engine, engine air intake technology, applied in the direction of engine components, machine/engine, engine lubrication, etc., can solve problems such as poor lubrication effect, improve lubrication effect, improve reliability and consistency, and avoid backflow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

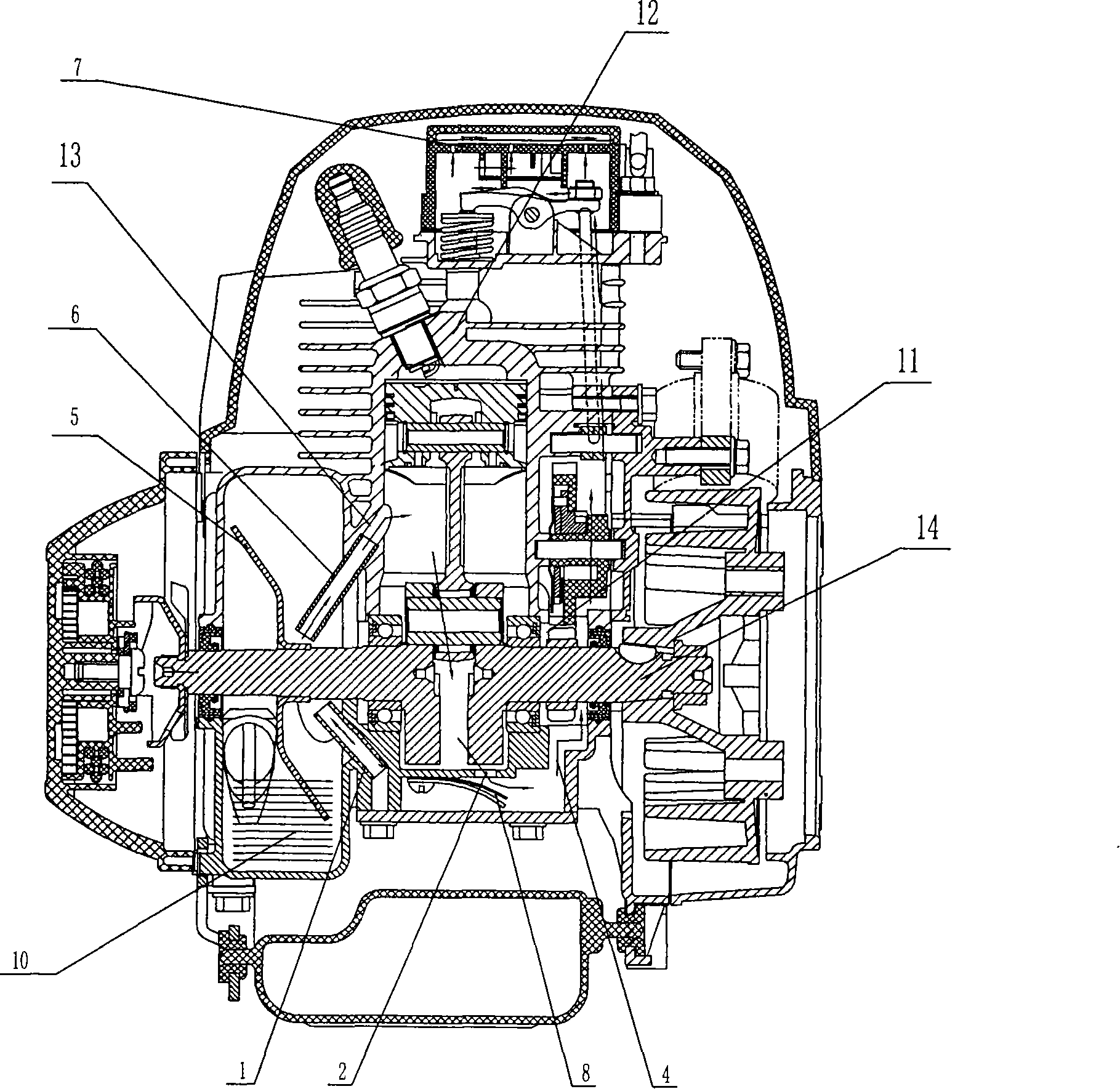

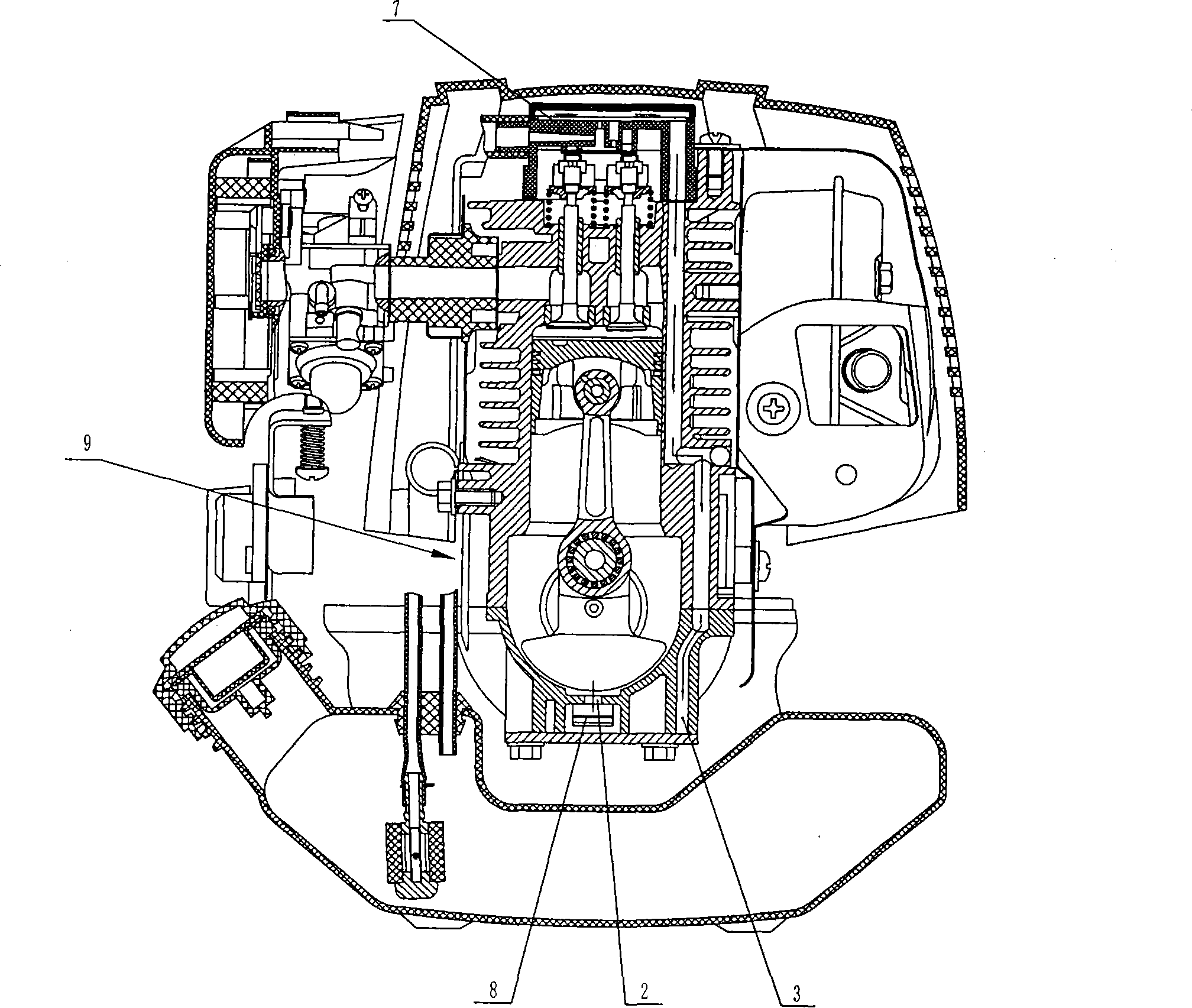

[0022] Such as figure 1 , 2 shown.

[0023] A kind of arbitrarily overturning four-stroke engine, comprises: diaphragm carburetor 9 (can adopt existing commercially available product to realize), by the pressure pulse pumping fuel of engine crank chamber, excess fuel is circulated to fuel tank (as figure 2 );

[0024] The oil storage chamber 10 is used to seal and store lubricating oil and is equipped with an oil mist generating device inside, and the crankshaft drives the oil mist generating device to generate lubricating oil mist;

[0025] Crankcase 11, check valve 8 is arranged at the bottom (reed structure can be adopted, as figure 1 As shown), the check valve 8 communicates with the valve control chamber 7. When the pressure rises, the check valve 8 opens, and when it drops, it closes; the lower part of the crankcase 11 is provided with an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com