Large axial flow fan unbalance recognition method based on auto-correlation

A technology of axial flow fan, identification method, applied in static/dynamic balance test, components of pumping device for elastic fluid, axial flow pump, etc., can solve assembly error, danger, difficult to obtain key phase correctly signal problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

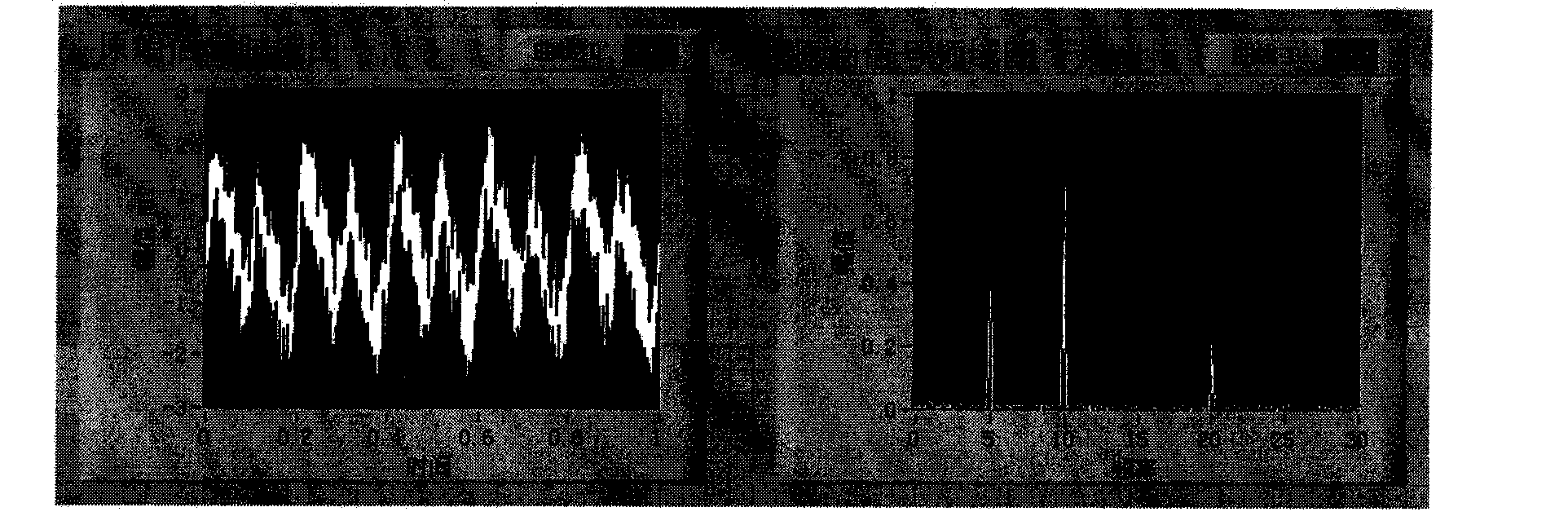

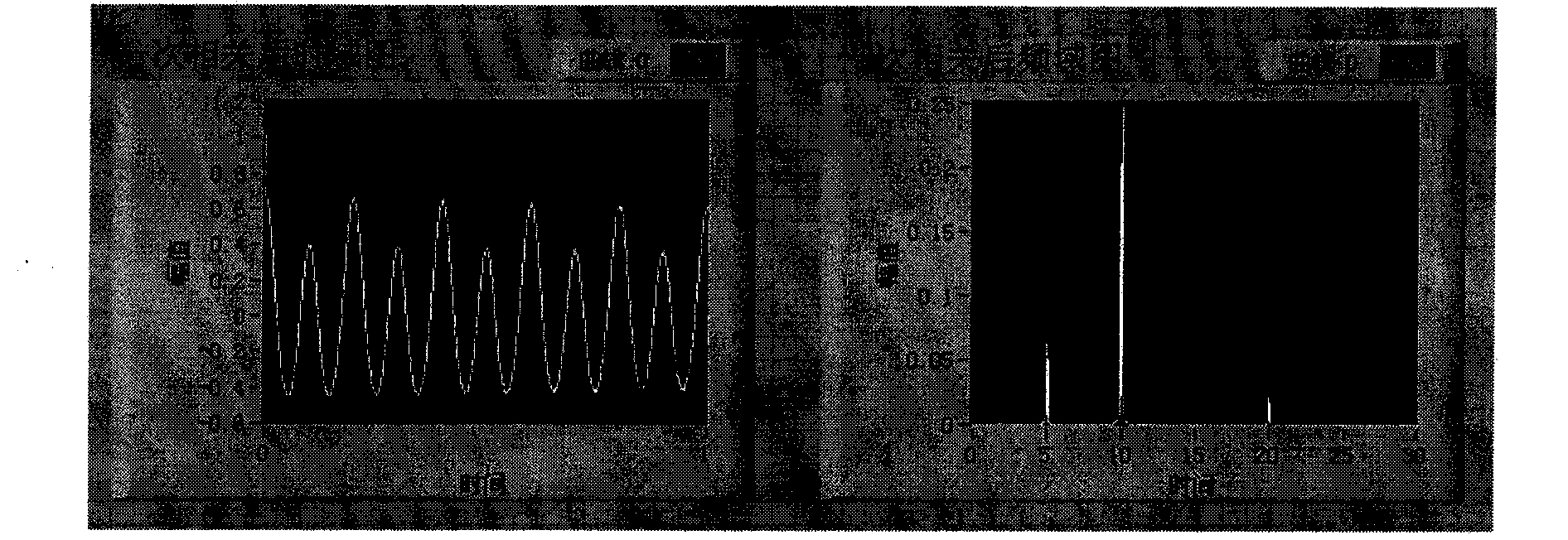

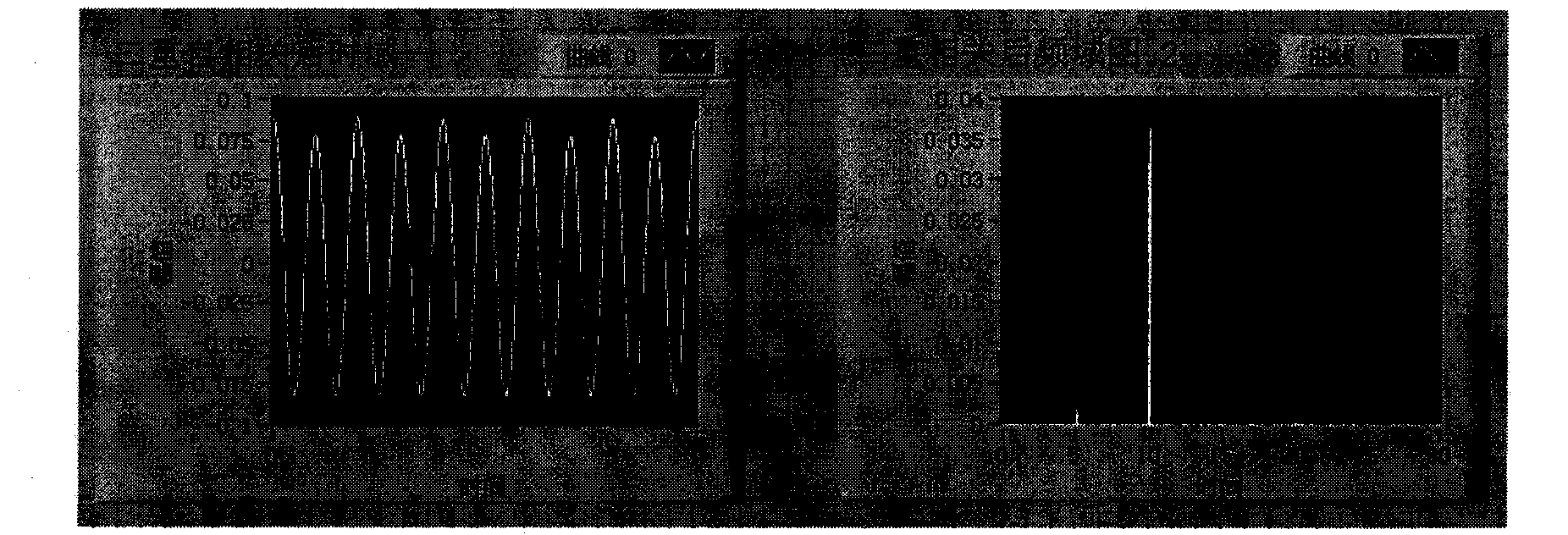

[0041] The method for identifying the unbalance of a large axial flow fan based on autocorrelation includes the following steps:

[0042] 1) Assuming that the vibration fault of the axial flow fan is caused by the unbalance, that is, the power frequency component in the vibration signal of the axial flow fan accounts for more than half of the total energy of the vibration signal of the axial flow fan, define the amplitude of the power frequency signal in the vibration signal of the axial flow fan and other The amplitude ratio of the frequency signal is greater than or equal to 2, and the sampling length is greater than the period of the rotational speed signal. The vibration signal of the axial flow fan includes power frequency components, half frequency components, double frequency components, other frequency components and noise signals. The vibration corresponds to the power frequency component of the vibration signal of the axial flow fan;

[0043] 2) Perform low-pass filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com