Pre-installing construction method and auxiliary device of contact type thermal meter probe

A thermal instrument, pre-installed technology, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as unfavorable product protection, easy damage, and equipment cannot be installed, so as to solve the phenomenon of pipe hole plugging and easy loading and unloading. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

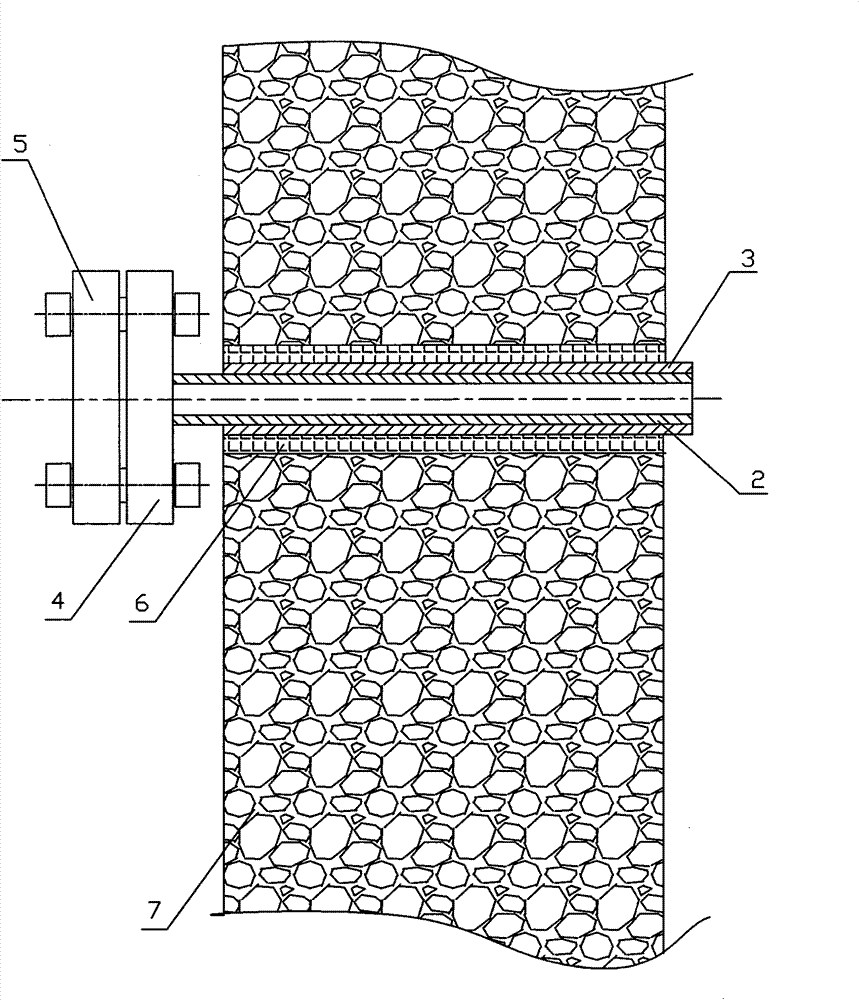

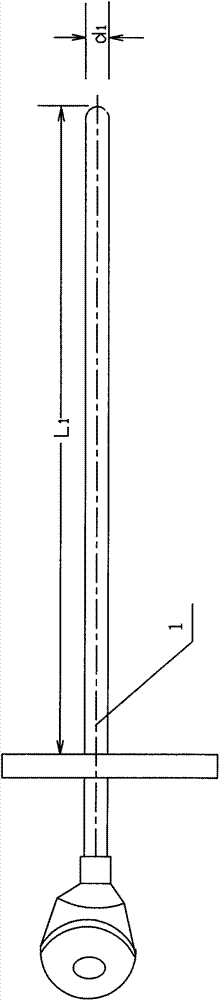

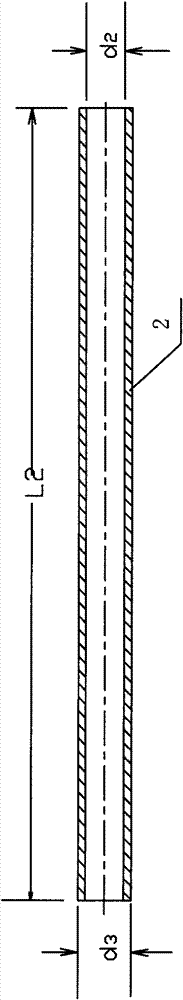

[0028] In order to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the embodiments and accompanying drawings, referring to Fig. 1 to Fig. image 3 :

[0029] A pre-installation construction auxiliary device for a contact type thermal instrument probe implemented according to the present invention, which includes a blind flange 5, a prosthetic steel pipe 2, a pre-embedded steel pipe 3, and a matching flange 4. The prosthetic steel pipe 2 The length is 1-2cm longer than the length of the instrumentation equipment, the inner diameter of the pre-embedded steel pipe 3 is 2-5mm larger than the outer diameter of the prosthetic steel pipe 2, the prosthetic steel pipe 2 is welded on the blind flange 5, and the end face of the prosthetic steel pipe 2 is vertically blinded. Lan 5 plane, the prosthetic steel pipe 2 center line and the blind plate flange 5 circle centers are on the same straight li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com