Small-size hydrogen flame ionization detector

A hydrogen flame and ionization technology, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of not being suitable for large-diameter capillary tubes and packed columns, and achieve the effect of simple structure, easy assembly, and reasonable positional relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

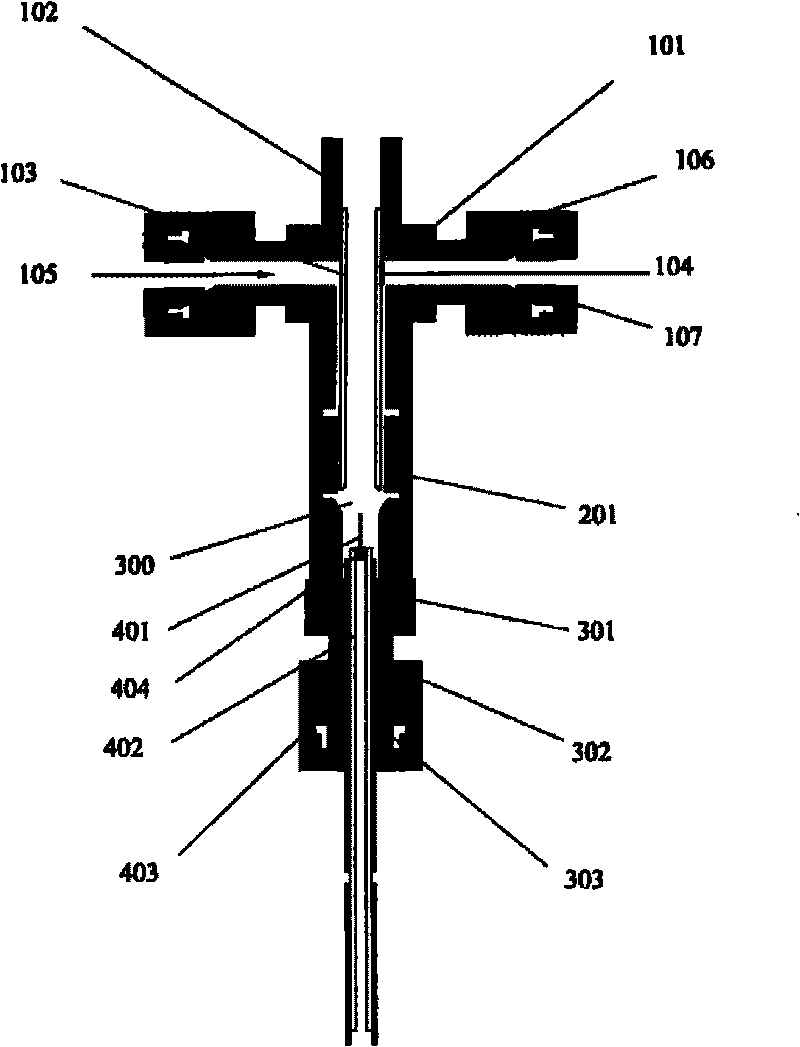

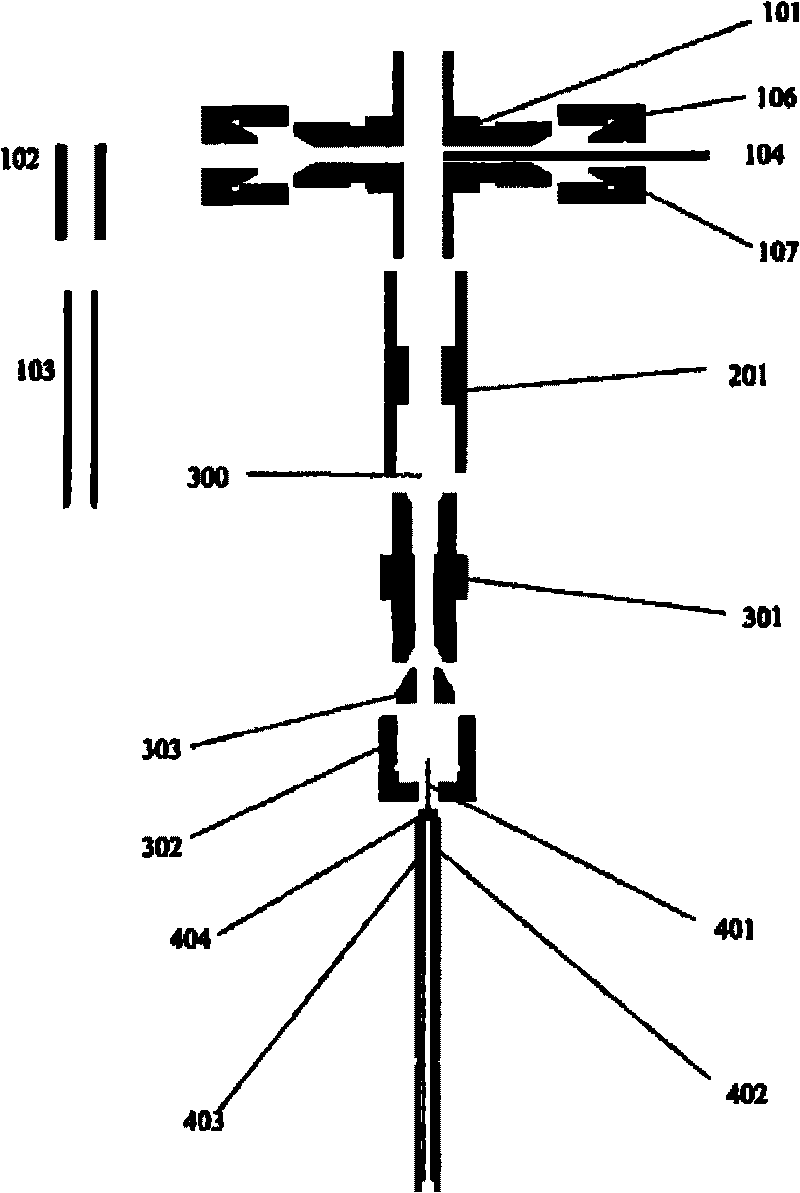

[0031] see figure 1 with figure 2 , a small ionization detector that can be used in portable gas chromatography, the components are shown in the figure.

[0032] A small-sized hydrogen flame ionization detector, including a four-way and a nozzle assembly, the two ports on the horizontal side of the four-way 101, the left and right ports are respectively the air inlet 105 and the outlet of the micro-current signal line 104, and the micro-current signal line 104 is drawn from a pressure The cap 106 is passed in series, the pressure cap 106 is blocked at the exit of the signal line, and the ferrule A107 is screwed together with the exit end of the micro-current signal line 104 of the cross 101;

[0033] A metal collector 103 is fixed in the longitudinal through hole of the four-way 101 through the high-temperature-resistant insulating sleeve A102, and the high-temperature-resistant insulating sleeve A102 is arranged inside the upper port of the four-way 101 in the longitudinal ...

Embodiment 2

[0050] 1. Polarized pole and nozzle:

[0051] 1.1 The introduction tube 402 is a nickel tube with a length of 30 mm, an inner diameter of 800 μm, and an outer diameter of 1.6 mm;

[0052] 1.2 Nozzle 401 is a stainless steel capillary tube with a length of 7 mm, an inner diameter of 250 μm, and an outer diameter of 790 μm, which is inserted into a nickel guide tube at a depth of 4022 mm and welded;

[0053] 2. The collector 103 is a stainless steel tube with a length of 24 mm, an inner diameter of 3 mm, and an outer diameter of 4 mm;

[0054] 3. The inner diameter of the upper and lower holes of the stainless steel cross 101 is 6.0mm, and the left and right ports are respectively used for the air pipeline and the lead wire of the collector;

[0055] 4. The inner diameter of the stainless steel two-way 301 is 4mm;

[0056] 5. M6×1 brass nut 401 and pressure cap 106, used for fixing and sealing the access parts of the pool body;

[0057] 6. The high temperature resistant insul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com