Method for improving magnet measuring precision of three elements

A three-component, high-precision technology, applied in the field of geophysical magnetic prospecting, can solve the problem of low precision, achieve the effect of improving the precision value and expanding the scope of prospecting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

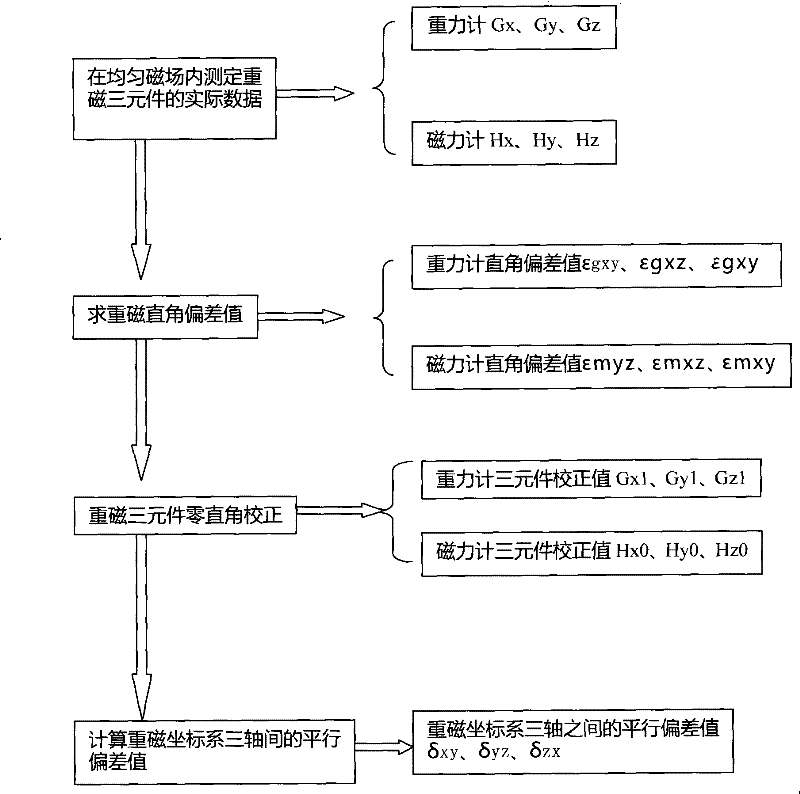

[0051] The implementation steps of the method of the present invention are further described by taking the following specific manner as an example.

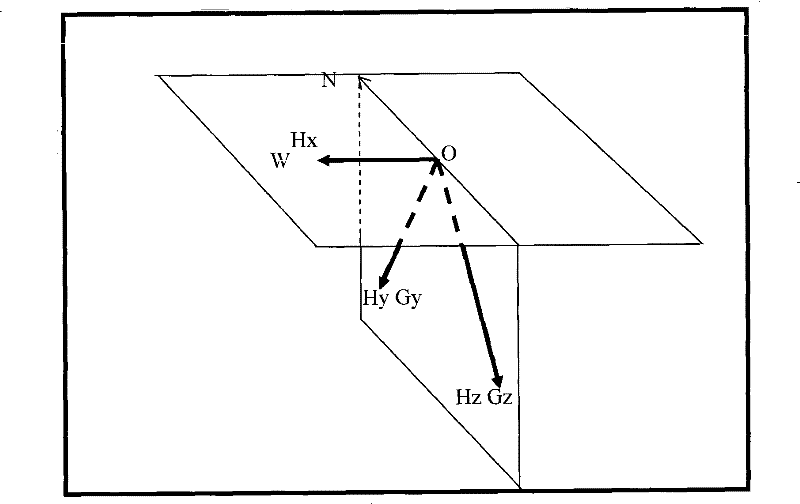

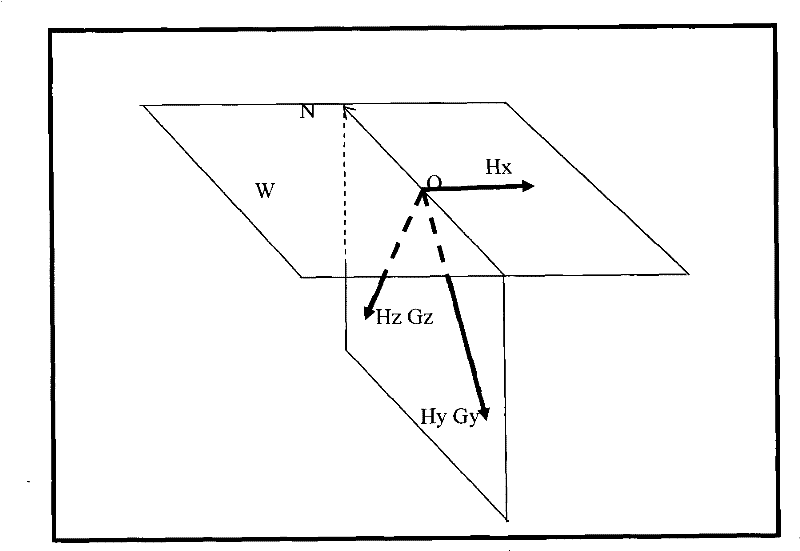

[0052]The applicant believes that the accuracy of the three-component magnetic measurement system in the well depends on the magnetic measurement accuracy of the system and the conversion accuracy from the axial system to the vertical system. The magnetic measurement accuracy is determined by the accuracy of the gravity, magnetic sensors and electronic circuits. The accuracy is determined by the three-axis right-angle deviation of the two axial coordinate systems composed of six gravity and magnetic sensors and the coincidence deviation of the gravity and magnetic coordinates. Due to the narrow space of the downhole probe, it is difficult to rely on mechanical adjustment Therefore, the coordinate conversion error is far greater than the system observation error. The main reason for the low accuracy of the three-component magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com