Terahertz wave polarizing beam splitter

A polarizing beam splitter and terahertz technology, applied in polarizing components, instruments, optics, etc., can solve problems such as difficult manufacturing process, low transmittance, and complex structure, and achieve simple structure, high transmittance, and high beam splitting rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

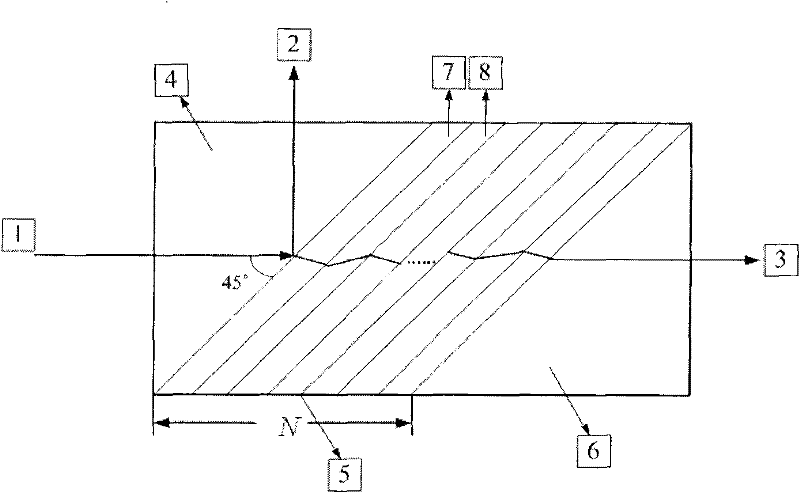

[0017] Terahertz wave polarizing beam splitter:

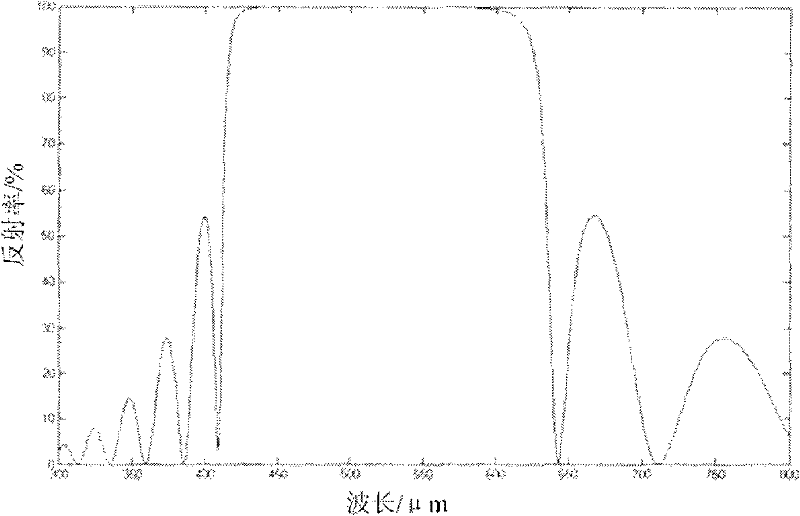

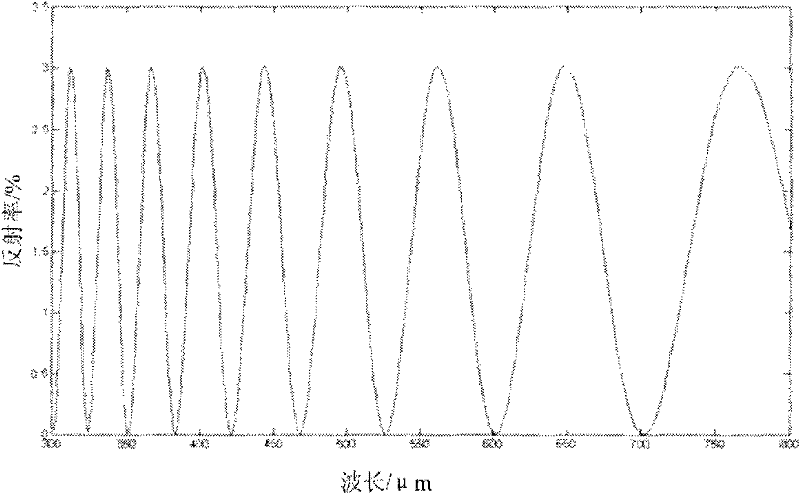

[0018] The first piece of far-infrared optical glass and the second piece of far-infrared optical glass are isosceles right-angled triangles, the refractive index of the far-infrared optical glass is 1.48, and the right-angle side is 20 mm. The refractive index of the first polarizing film is 3.6, the refractive index of the second polarizing film is 2.45, the length of the first polarizing film and the second polarizing film are equal, which is 1.8 μm, and the incident angle of unpolarized light incident on the film polarizer is 45° °. The film polarizer 5 is formed by alternately connecting 10 layers of first polarizing films and 9 layers of second polarizing films, that is, N=19. The TE wave reflectivity curve of the terahertz wave polarizing beam splitter is as follows figure 2 As shown, the maximum reflectance is 99.9%. The TM wave reflectivity curve of the terahertz wave polarizing beam splitter is as follows image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com