Ultra-thin light-emitting diode (LED) display

A technology of light-emitting diodes and displays, which is applied in the direction of instruments, electric solid-state devices, semiconductor devices, etc., and can solve problems such as high astigmatism rate and hazy light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

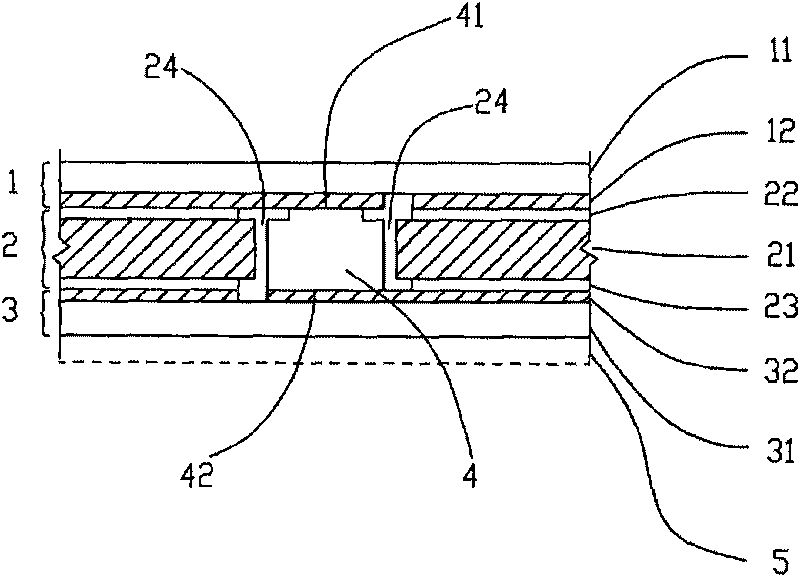

[0031] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and explained below in accordance with the drawings and in combination with the best embodiments of the present invention.

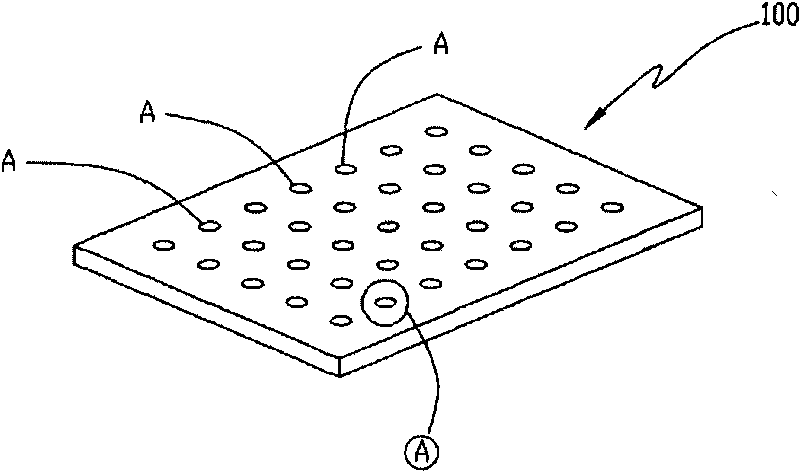

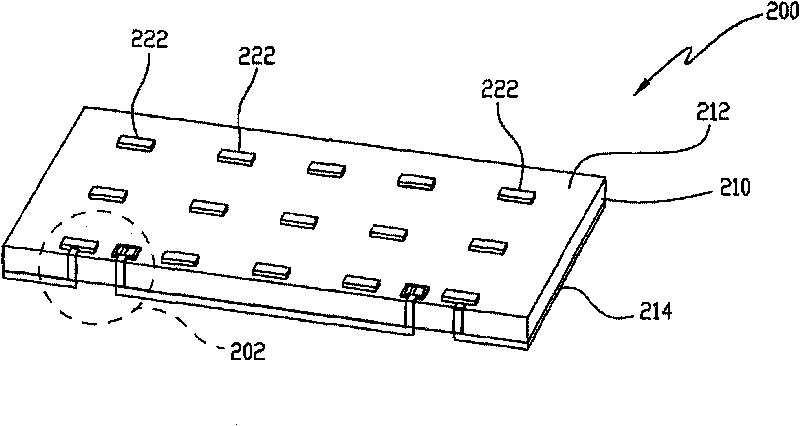

[0032] The ultra-thin light-emitting diode display 100 of the present invention is characterized in that it includes: a top layer 1, a middle layer 2, a bottom layer 3, and a plurality of light-emitting diode crystal grains 4; Layer 5.

[0033] Top layer 1, is a transparent film 11, and its base material is macromolecular transparent plastics, as polyethylene terephthalate (PET) or cyclic olefin copolymer (COC), on one side of transparent film 11, use vacuum evaporation Or sputter conductive substances, such as indium tin oxide (ITO), aluminum zinc oxide (AZO) or indium zinc oxide (IZO), as the transparent conductive film 12; Wet film and dry film wet film mixing method; using photoresist or phot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com