Assembling method and assembling tool for memory and radiating plate

An assembly method and memory technology, applied in cooling/ventilation/heating transformation, semiconductor/solid-state device manufacturing, instruments, etc., can solve the problems of occupying space, inability to combine, and complicated manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to further understand the features and technical contents of the present invention, please refer to the following detailed description and drawings related to the present invention, but the attached drawings are only for reference and illustration, and are not intended to limit the present invention.

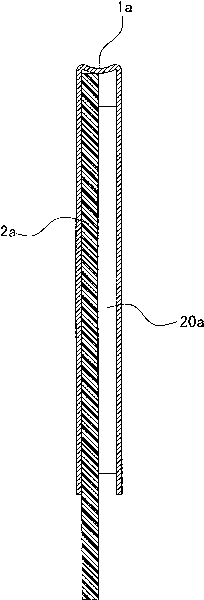

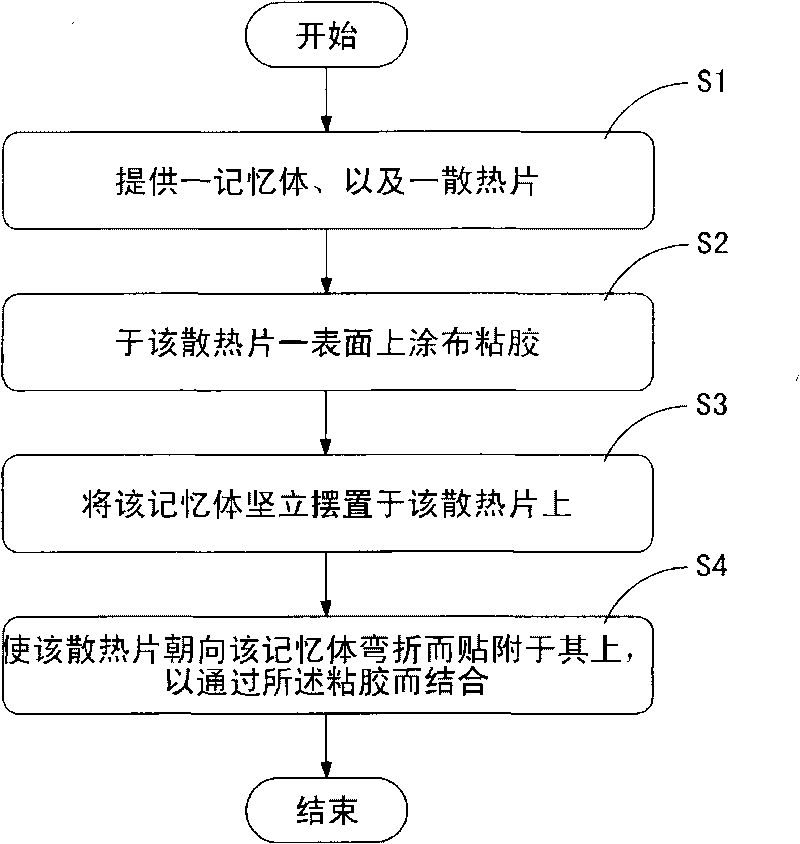

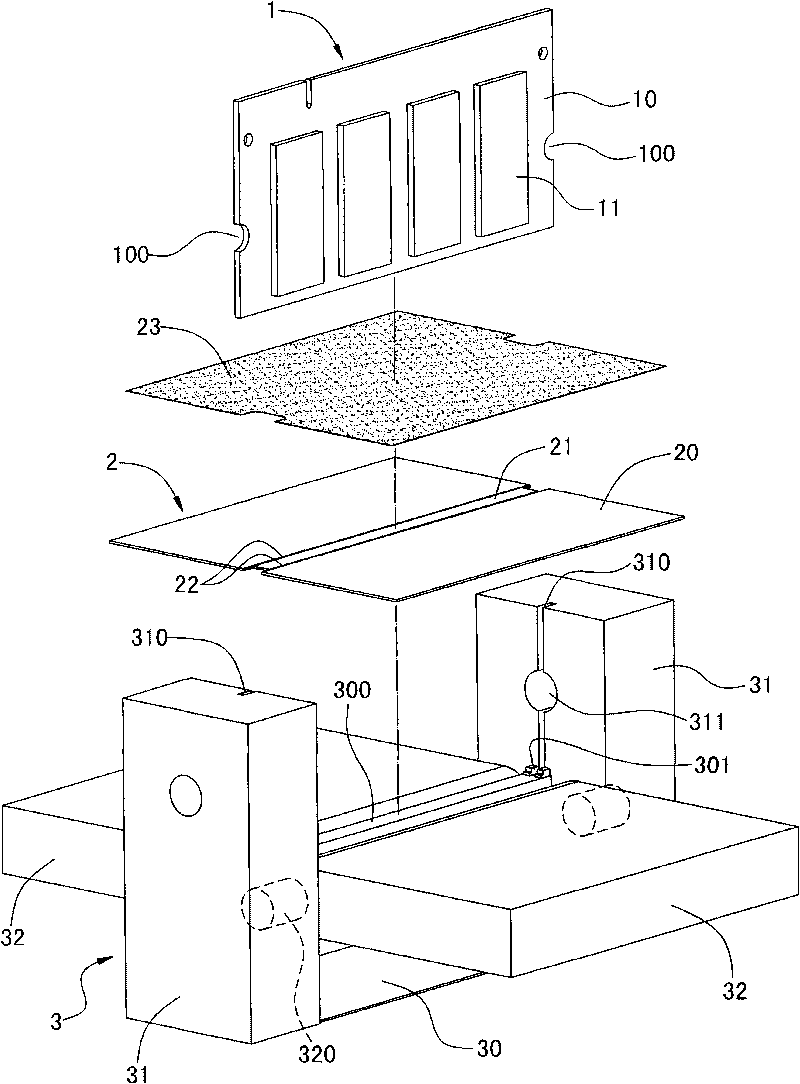

[0047] The invention provides a method for assembling a memory and its cooling fins and a tool thereof. Please see first image 3 and Figure 6 As shown, the assembly tool 3 includes a platform 30, two positioning arms 31, and two splints 32; wherein:

[0048] The platform 30 is a seat of the assembly tool 3 for carrying the above-mentioned components to form a tool. In addition, the two positioning arms 31 are vertically arranged on the platform 30 opposite to each other at intervals, and on the inner side walls corresponding to each other of the two positioning arms 31, a groove 310 extending vertically from top to bottom is provided for The two sides of a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com