Lithium battery

A lithium battery and battery technology, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as affecting the connection firmness of the pole and the tab, affecting the sealing between the pole and the cover, and limited contact length. , to prevent radial movement, increase contact length, and enhance sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

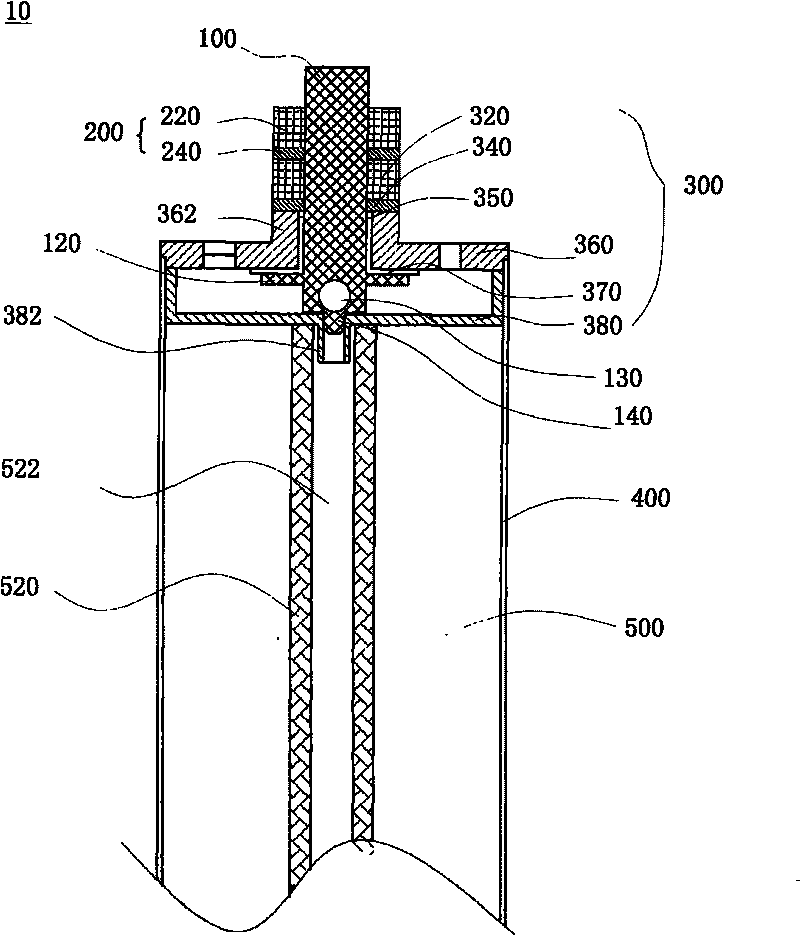

[0046] Such as figure 1 As shown, the lithium battery 10 includes a battery cover assembly 300 , a pole 100 , a battery case 400 and a battery core 500 . The pole 100 passes through the battery cover assembly 300 and is connected to the battery core 500 sealed in the battery casing 400 by the battery cover assembly 300 .

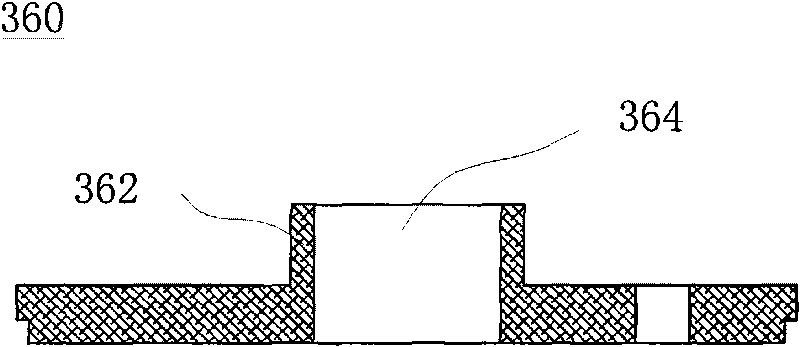

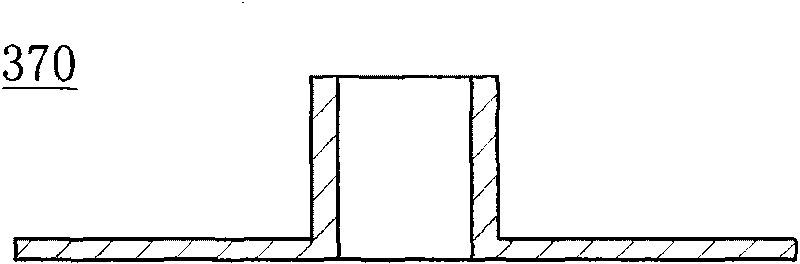

[0047] The battery cover assembly 300 includes a battery cover 360 , an insulator 370 and an insulating spacer 380 . The battery cover 360 is welded on the top of the battery case 400 . The insulating spacer 380 is disposed between the battery cover 360 and the battery core 500 , and its outer wall size is consistent with the inner wall size of the battery case 400 . The tabs (not shown) on the battery core 500 are connected to the pole 100 through the insulating spacer 380 .

[0048] The battery cover 360 is generally connected to the top of the battery case 400 by welding. The pole 100 passes through the battery cover assembly 300 into the interior of ...

Embodiment 2

[0058] On the basis of Example 1, as Image 6 As shown, the pole hole 364 can be a cone with a small upper opening and a large lower opening (such as a cone or a regular polygonal pyramid), and the corresponding part of the pole 100 is a corresponding cone (such as a cone or a regular polygonal pyramid). When the fastening nut 320 is tightened, it will drive the pole 100 to move upwards. Because the opening at the upper end of the pole hole 364 is small, the gap between the tapered part of the pole 100 and the pole hole 364 becomes smaller when the pole hole 364 moves up, which can strengthen seal.

Embodiment 3

[0060] When the fastening nut 320 presses the battery cover 360 , or hits the pole 100 during transportation, the boss 362 will be under pressure from the pole 100 and the fastening nut 320 . In order to increase the stress on the boss 362, the following improvements can be made on the basis of the foregoing embodiments:

[0061] The outer surface of the boss 362 is an arc-shaped ball table-shaped protrusion. The so-called ball table refers to the part of the sphere that is cut by two parallel planes and sandwiched between the two planes. that is, Figure 5 As shown, from the battery cover 360 to the top of the boss 362, the radial dimension of the boss 362 decreases in an arc shape. Under this structure, on the one hand, the thickness of the joint between the boss 362 and the battery cover 360 is enhanced, which can withstand greater pressure. On the other hand, the arc structure can reduce stress concentration after compression and avoid cracks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com