Inertia estimating controller and control system

A control device and motor technology, which is applied in the field of inertia estimation control devices and control systems, and can solve problems such as the reduction of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described below with reference to the drawings.

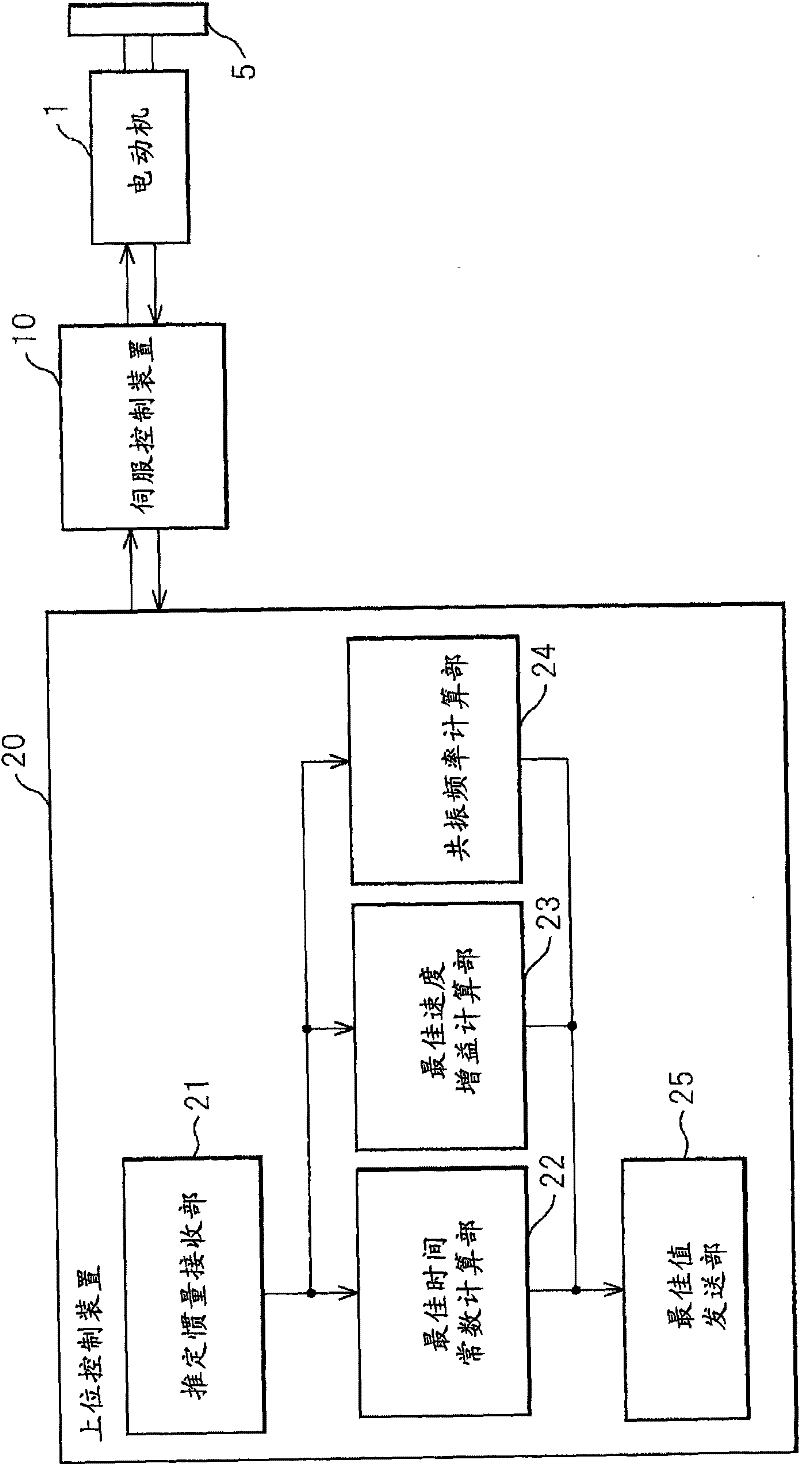

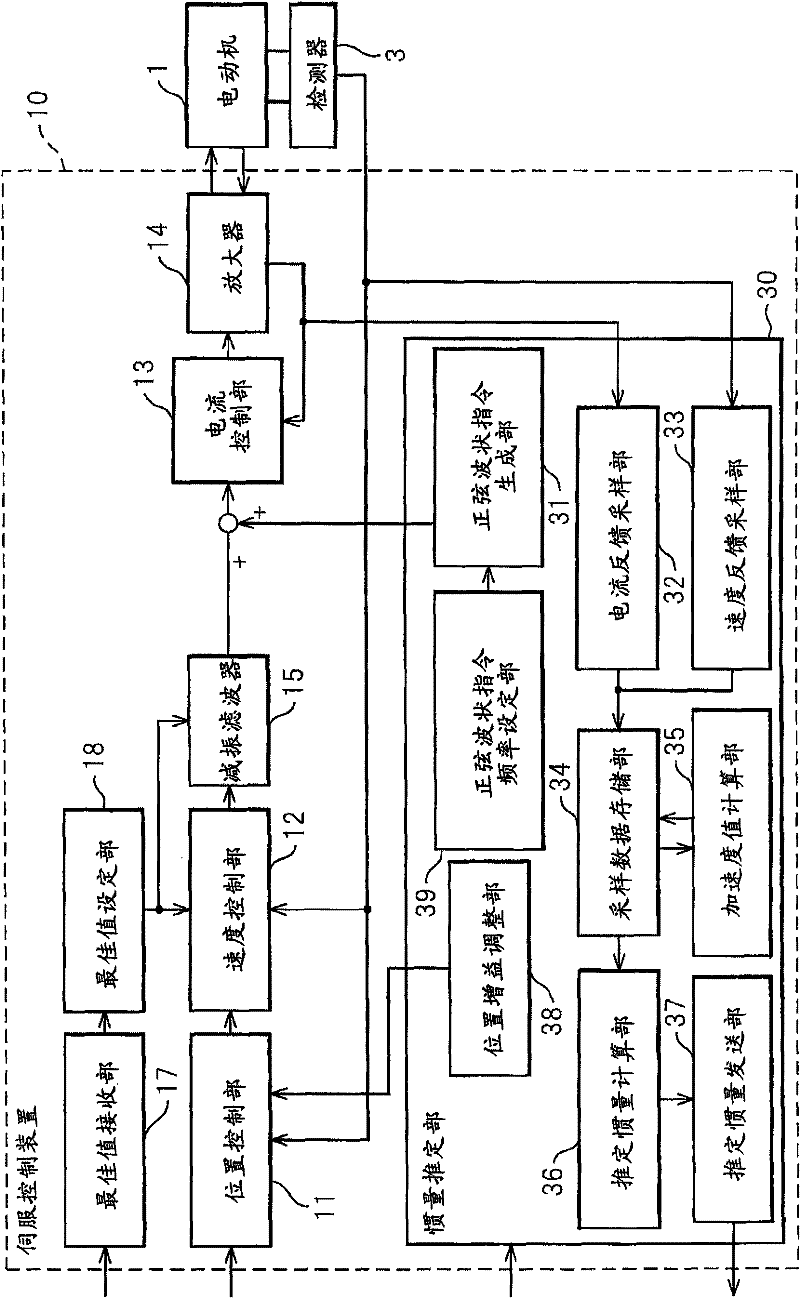

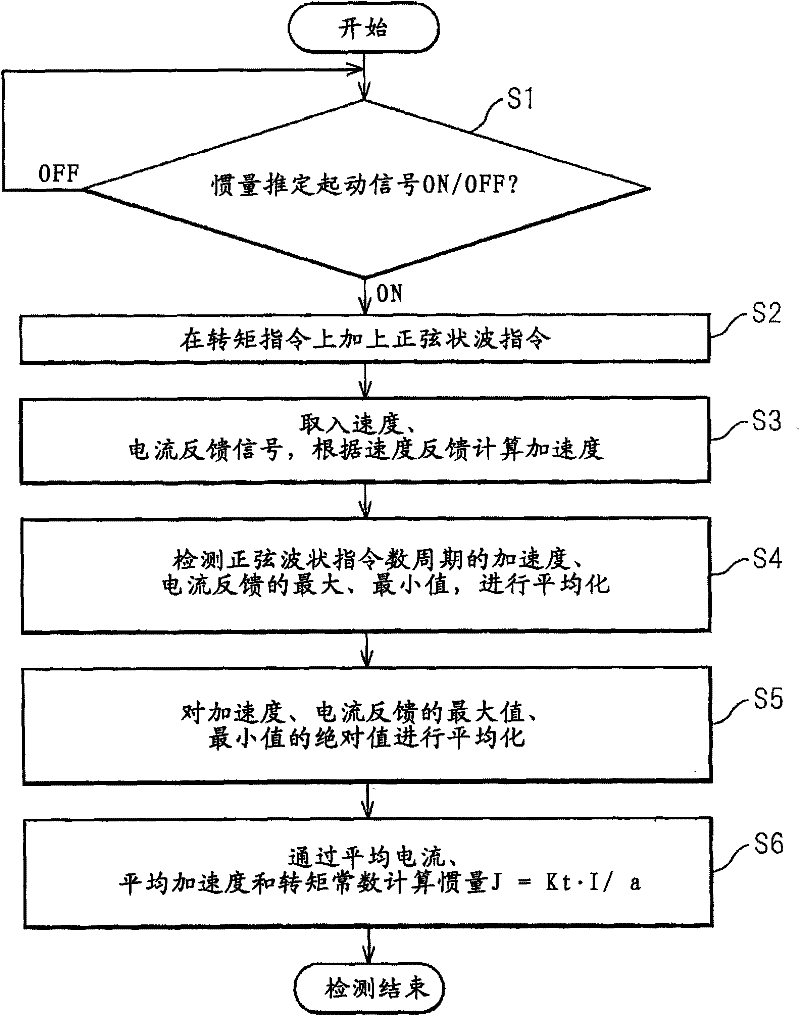

[0027] figure 1 It is a block diagram showing the structure of the control system of this embodiment. As shown in the figure, the control object in this embodiment is the motor 1 that operates the driven body 5 . The motor 1 is used, for example, to change the position or posture of a table holding a workpiece in a machine tool, or to rotate an arm of a robot. The driven body 5 driven by the motor 1 may include a table, a robot arm, and a workpiece that can be mounted or detached thereon, and may also include an operating part of the motor 1 itself.

[0028] The position, speed and torque of the motor 1 are controlled by a servo control device 10 . The servo control device 10 is connected to a host control device 20 such as a CNC (numerical control device) or an external device that issues commands for the position, speed, and torque of the motor 1 in accordance with the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com