Apparatus for adjusting the degree of freedom using sensor in assembling optical device

An optical device, a technology of degrees of freedom, applied in the directions of optics, optical components, installation, etc., can solve problems such as difficulty in adjusting degrees of freedom, deterioration of image quality, and image distortion, and achieve the effect of overcoming image distortion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

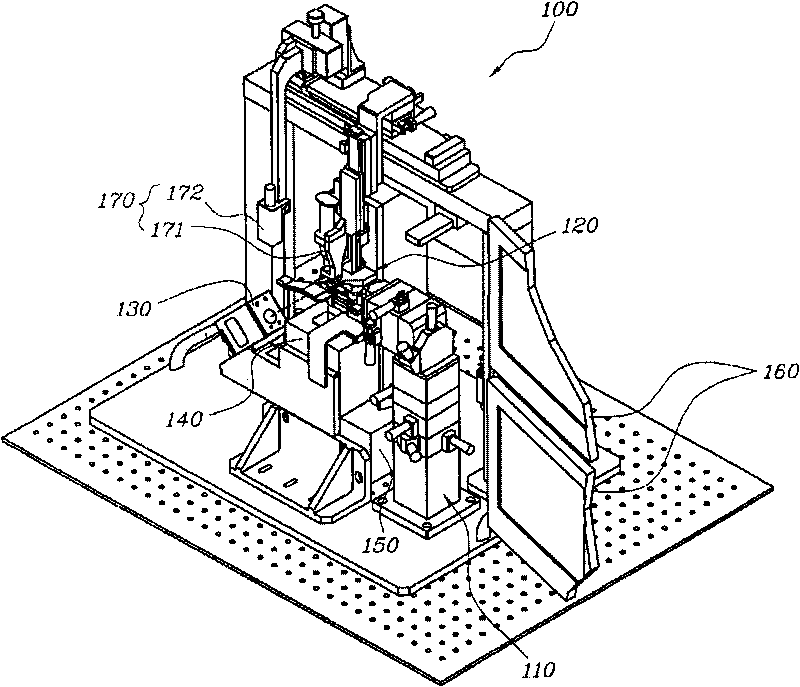

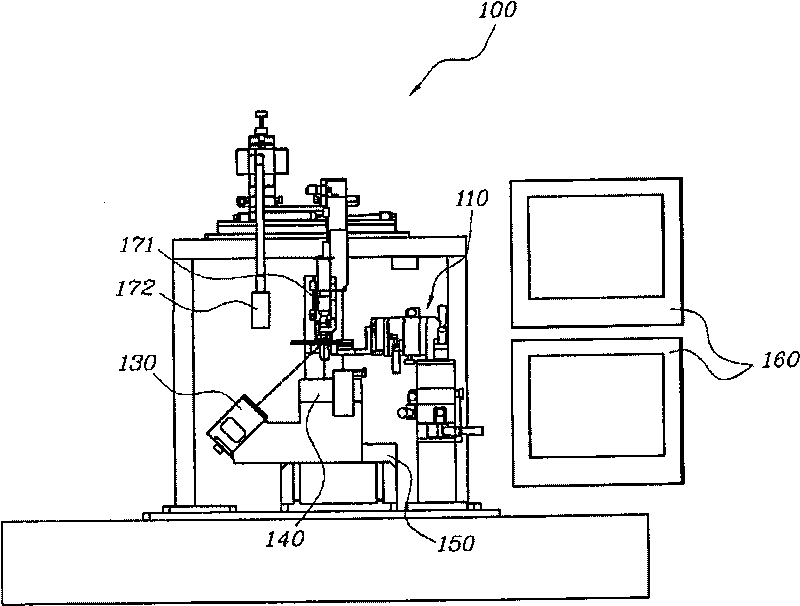

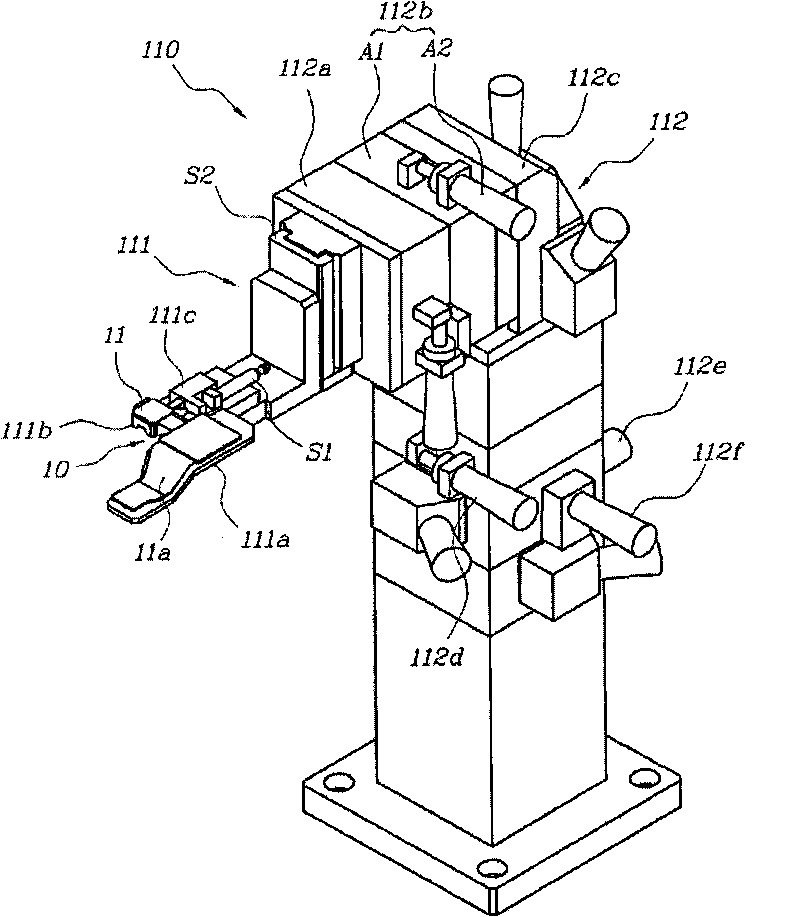

[0030] Such as Figure 1 to Figure 8 As shown, the optical arrangement using the device 100 according to the present invention to adjust the degree of freedom by the sensor during assembly comprises: a printed circuit board (PCB) assembly 10 having a PCB board 11 and an image surface mounted on the PCB board 11 The sensor 12 ; the lens assembly 20 ; and the fixing plate 30 as a connection medium connecting the lens assembly 20 to the PCB assembly 10 .

[0031] The device 100 also includes: a degree of freedom adjustment unit 110, the degree of freedom adjustment unit 110 has a holder 111 and an error control part 112 connected to the holder 111, the holder 111 is used to firmly support the PCB assembly 10, and the error control part 112 is used to During the surface mount image sensor 12, the error is corrected by controlling the position of the holder 111 to adjust the degree of freedom; the board fixing unit 120, the board fixing unit 120 has a fixing jig 121 for firmly load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com