Artificial meal forming machine

A molding machine and artificial meat technology, which is applied in the field of soybean protein food processing equipment, can solve problems such as insufficient puffing, affecting food hygiene and safety, and short screws, and achieve the effect of improving fiber and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

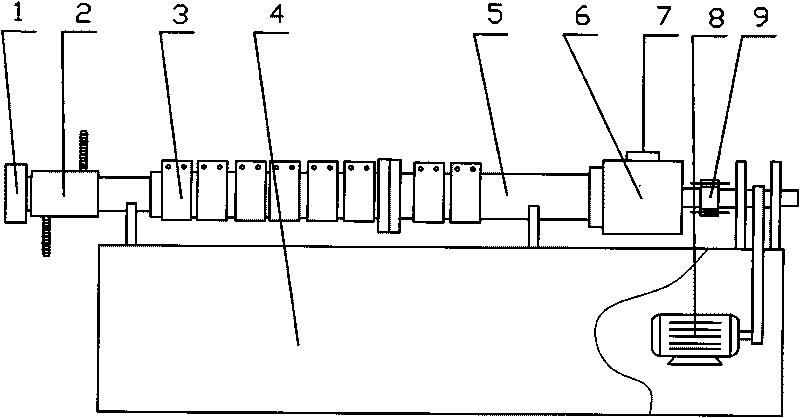

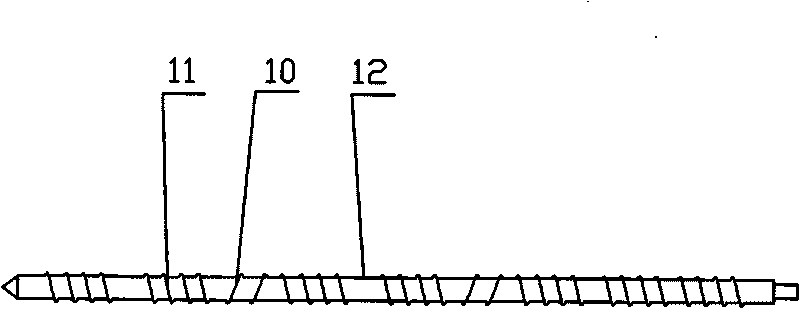

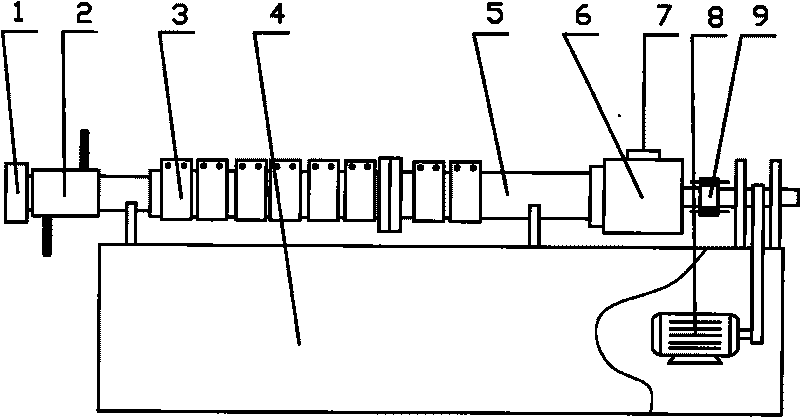

[0019] Such as figure 1 , figure 2 An artificial meat forming machine is shown, which includes a frame body 4, a power part, a feeding part, and a working part. The power part, the feeding part, and the working part are installed on the frame body 4; the feeding part includes a material chamber 6, Feeding port 7, the right end of the screw sleeve 5 of the material chamber; the power part includes the motor 8 and the transmission mechanism; the working part includes the heating element 3, the screw 12 and the screw sleeve 5, the heating element 3 is covered on the outside of the screw sleeve 5, and the screw 12 is located on the screw In the sleeve 5, the motor 8 drives the screw 12 to rotate through the speed change mechanism. In the working part, the right end of the screw 12 is connected with a shaft sleeve through a sliding key. The shaft sleeve is connected with the motor 8 through a transmission mechanism. The inner surface of the shaft sleeve is designed with threads. 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com