Simple dispenser

A glue dispenser and simple technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of inconvenient operation, prone to deviation, delayed work time, etc., to achieve easy dispensing operation and improve production. Efficiency, high product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with accompanying drawing:

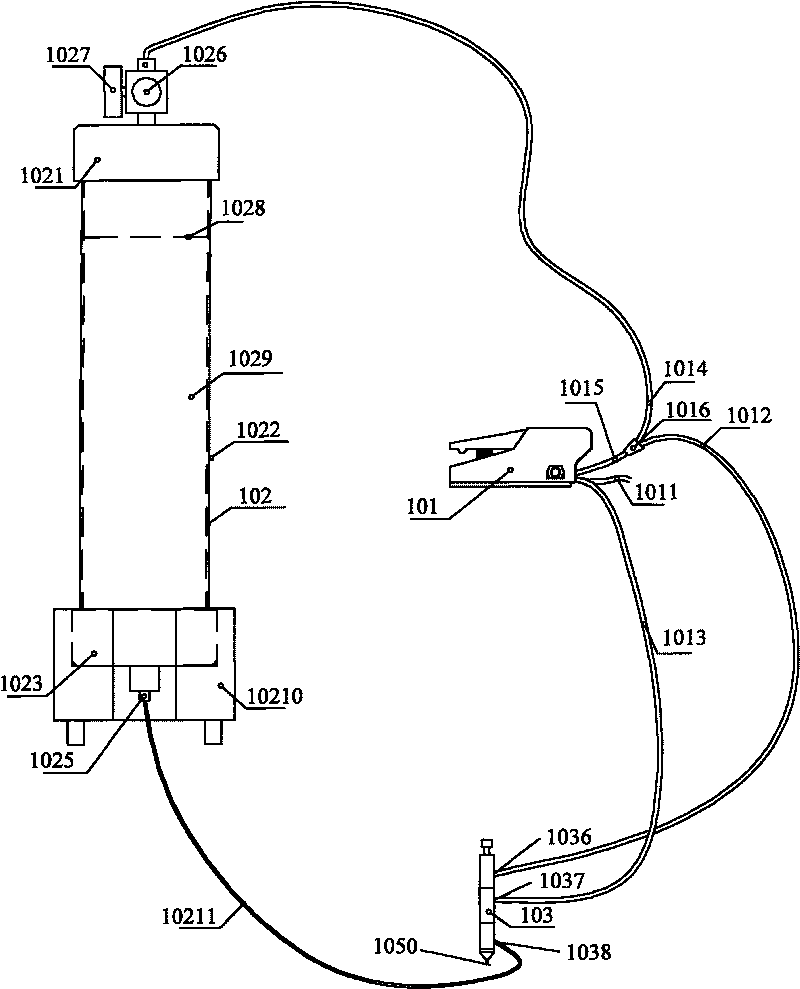

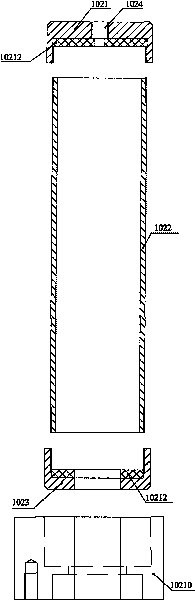

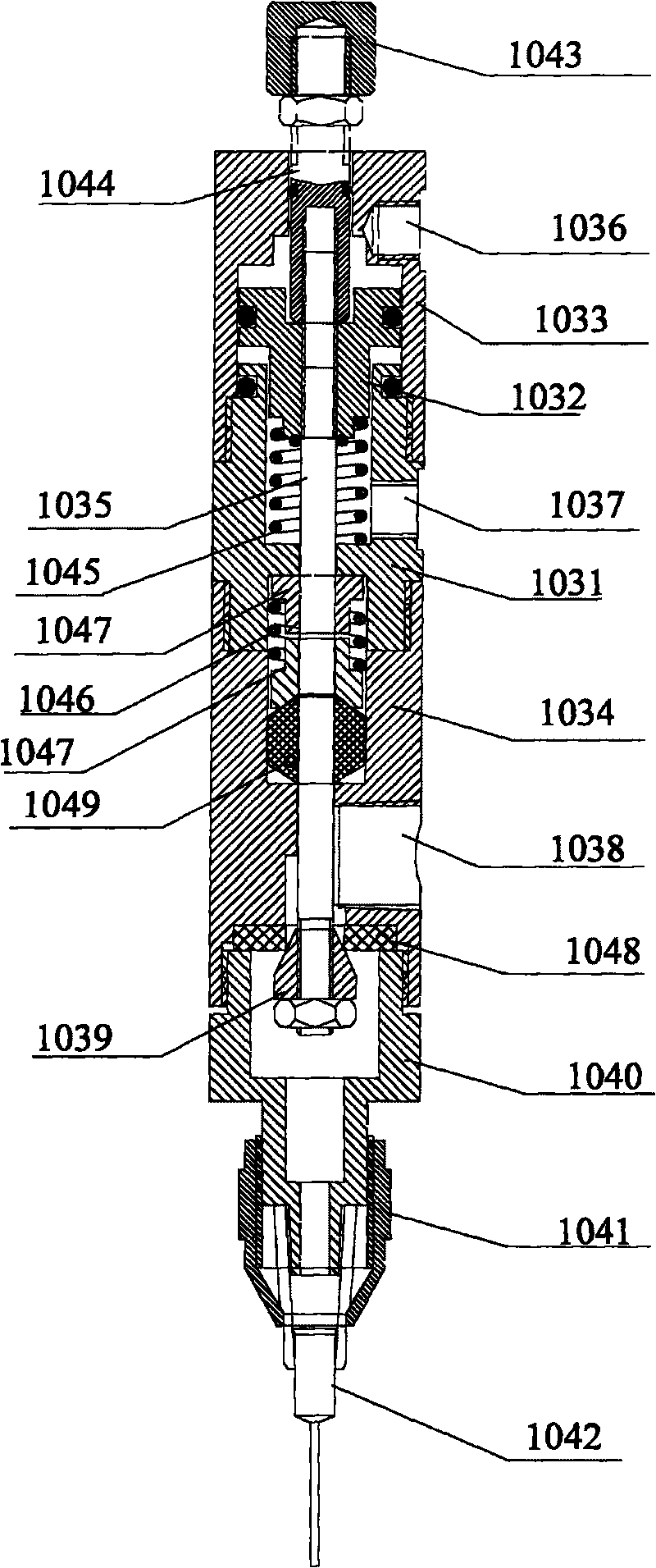

[0031] like figure 1 As shown, the simple dispensing machine provided by the present invention includes an air source, an air source controller 101, a closed barrel 102 that can accommodate glue, and a dispensing valve 103. The air source controller 101 includes an air inlet The first air outlet, the second air outlet, and the air inlet are connected to the air source through the first air pipe 1011 . In this embodiment, the air source is an air compressor, and the air source controller 101 is a foot valve that controls the opening and closing of the first air outlet and the second air outlet. like image 3 As shown, the main body of the dispensing valve 103 is cylindrical in shape. The dispensing valve 103 includes a cylinder, a piston 1032 disposed in the cylinder, a piston connecting rod 1035 connected to the piston 1032 and inserted in the cylinder, and a dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com