Powder material special for space-based weapons

A technology of powder materials and weapons, applied in the field of nano-scale metal powder materials, can solve problems such as the unimaginable degree of attack and "destruction" of earth targets, and the development of aerospace technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

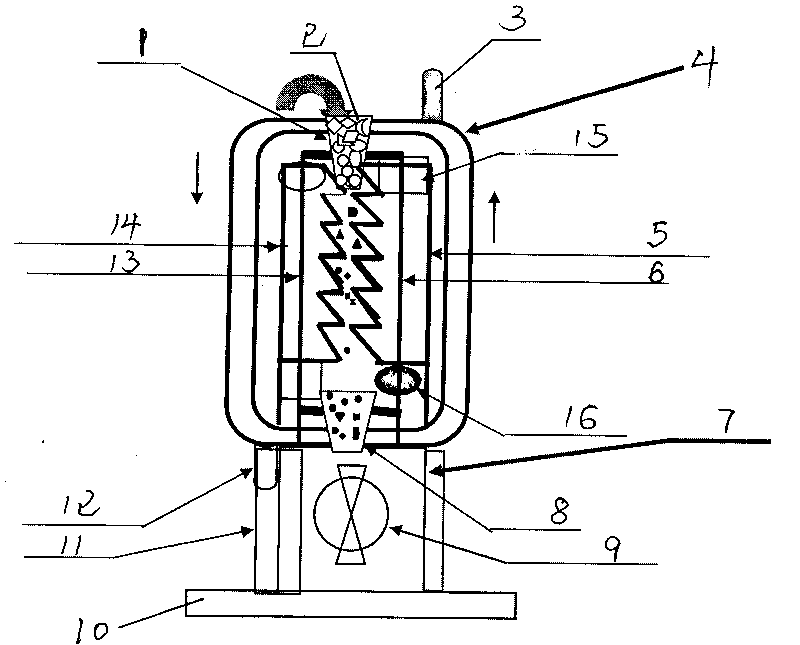

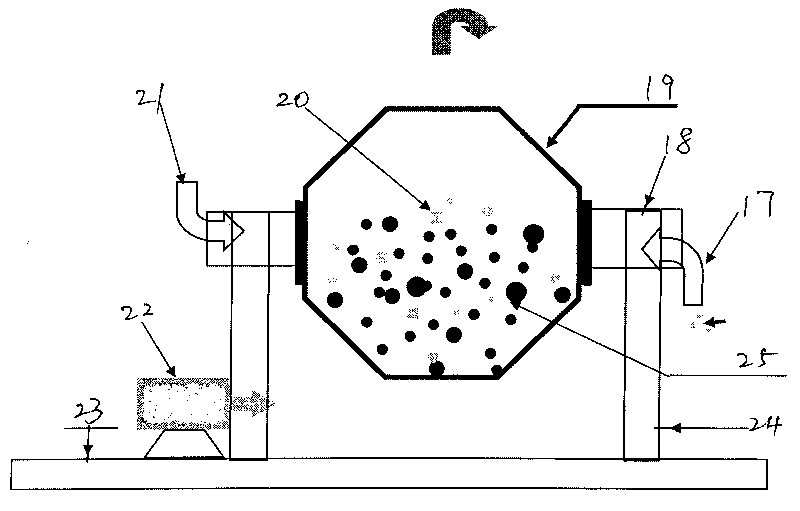

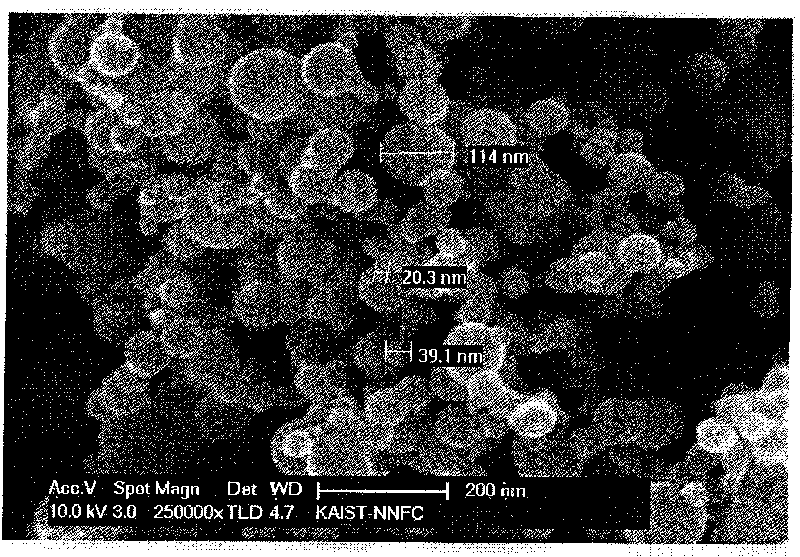

[0024] Example 1, a special powder material for space-based weapons, is prepared by the following method, (for the specific processing method, refer to the metal nano powder zero-boundary particle cutting production process recorded in Patent Application No. 2006100481685,) at -5°C Under the condition that the frequency of high-frequency cutting is set at 5500 times per minute, the special nano-iron powder (nano-titanium powder, nano-tungsten powder, nano-lead powder) whose powder particle shape is irregular sphere is produced and processed, and then divided into Select (500nm is example) D3=42.21nm D25=262nm D50=500nmD75=677.2nm D97=930.3nm The particle distribution of larger powder material, then reuse (patent application number is that 2006101620469 discloses a kind of metal micro, Nano particle coating process), "DQ coating method" continues the anti-oxidation coating on the iron powder particles with a thickness of 1nm-3nm, so that the anti-oxidation time can reach more th...

Embodiment 2

[0029] Example 2, a special powder material for space-based weapons is prepared by the following method. In the case of 5°C, the number of high-frequency cutting is set at 5500 times per minute to produce and process the powder particle shape to be different The special nano-iron powder (nano-titanium powder, nano-tungsten powder, nano-lead powder) of the regular sphere, and then sorted out (500nm as an example) particles with D3=42.21nm D25=262nm D50=500nm D75=677.2nmD97=930.3nm For powder materials with a relatively large distribution, the "DQ coating method" is used to continue the anti-oxidation coating on the iron powder particles with a thickness of 1nm-3nm, so that the anti-oxidation time can reach more than 90 hours.

[0030] According to the characteristics of the use requirements, the coated powder material is input into a high-speed grinder for surface treatment of the powder particles to make the surface of the powder particle material rough and uneven.

Embodiment 3

[0031] Example 3, a special powder material for space-based weapons is prepared by the following method. In the case of 0°C, the number of high-frequency cutting is set at 5250 times per minute to produce and process the powder particle shape to be different The special nano-iron powder (nano-titanium powder, nano-tungsten powder, nano-lead powder) of the regular sphere, and then sorted out (500nm as an example) particles with D3=42.21nm D25=262nm D50=500nm D75=677.2nmD97=930.3nm For powder materials with a relatively large distribution, the "DQ coating method" is used to continue the anti-oxidation coating on the iron powder particles with a thickness of 1nm-3nm, so that the anti-oxidation time can reach more than 90 hours.

[0032] According to the characteristics of the use requirements, the coated powder material is input into a high-speed grinder for surface treatment of the powder particles to make the surface of the powder particle material rough and uneven.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com