Powder transferring control device of powder forming machine

A powder molding machine and control device technology, applied in presses, manufacturing tools, etc., can solve the problems of complex mechanism, inconvenient installation and debugging, unstable transfer time and distance, etc., to achieve convenient installation and debugging, and stable and reliable transfer force. , to ensure the effect of powder transfer time and distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

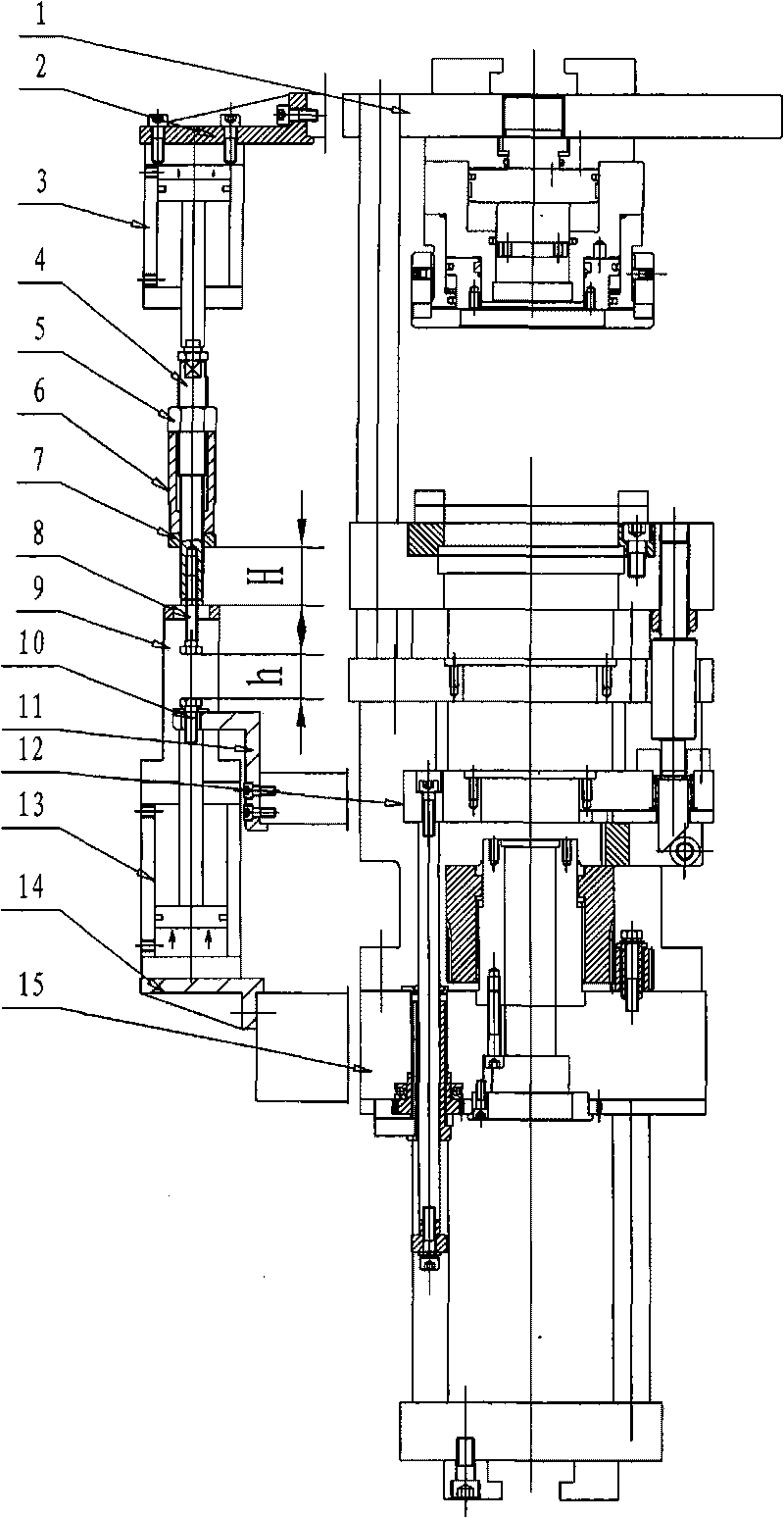

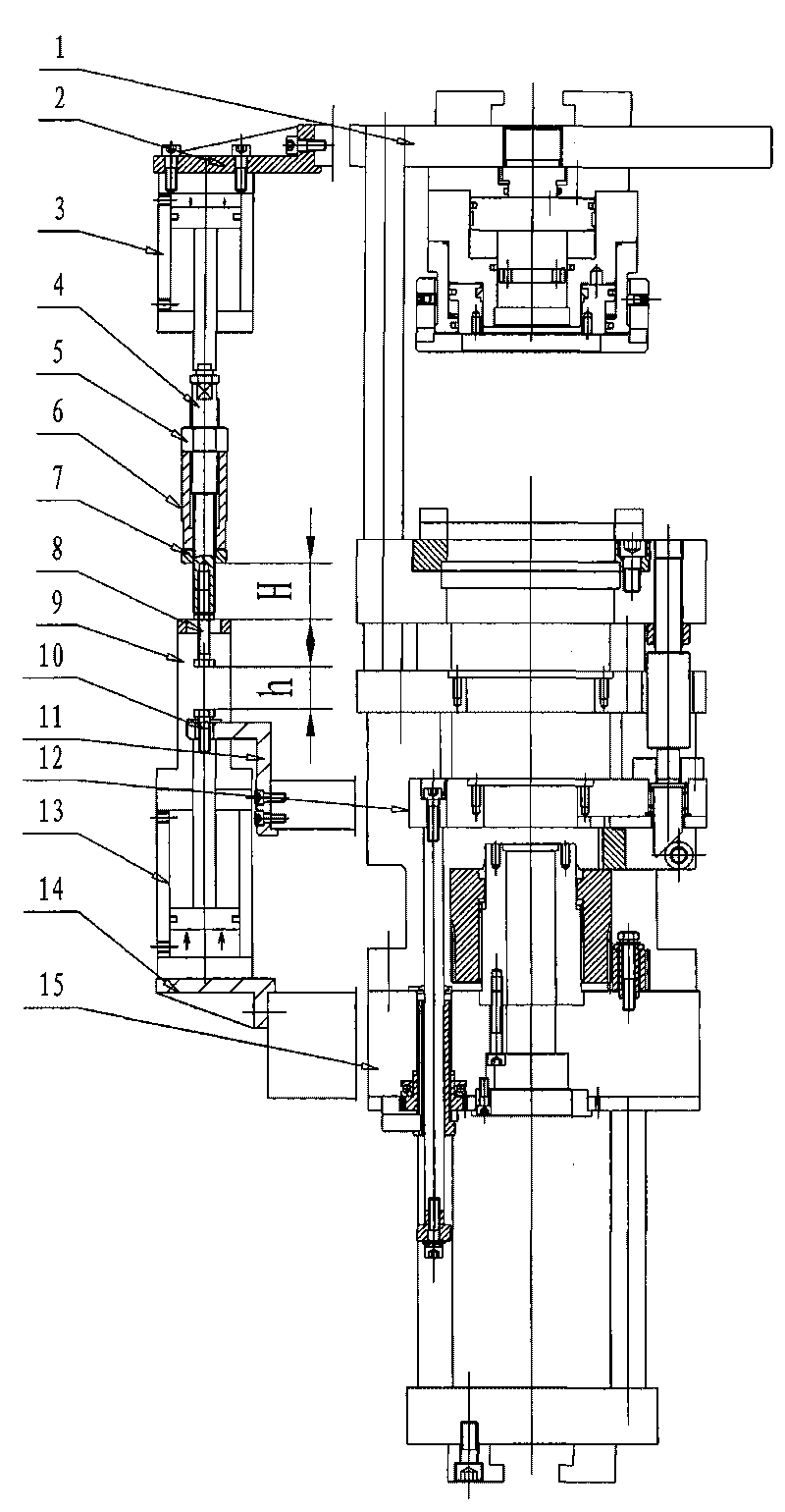

[0008] The present invention is arranged symmetrically on the front and back sides of the formwork, each side includes a powder transfer cylinder 3 connected to the upper template 1 through a powder transfer cylinder bracket 2, the lower part of the piston rod of the powder transfer cylinder 3 is connected to the adjustment screw 4, and the adjustment screw 4 is covered There is a powder-moving screw sleeve 6, and the powder-moving screw sleeve 6 extends downward to a powder-moving bolt 8, and the powder-moving screw sleeve 6 is provided with a powder-moving limit seat 9 that restricts the downward displacement of the powder-moving screw sleeve 6, and the powder-moving limit Bolt 10 cooperating with powder moving bolt 8 is extended upwards in seat 9, and reset cylinder 13 which is fixedly connected with lower fixed punching plate 15 is connected to the bottom of powder shift limit seat 9, and the piston rod of reset cylinder 13 extends to the powder shift limit. Inside the seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com